Device and method for catalyzing lignite to prepare methane directly

A methane and lignite production technology, applied in the manufacture of combustible gas, bulk chemical production, granular/powdered fuel gasification, etc., can solve the problems of increasing investment in air separation equipment, large water consumption, and limited economic benefits, and achieve savings Effects of space and equipment investment, investment cost reduction, and water conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

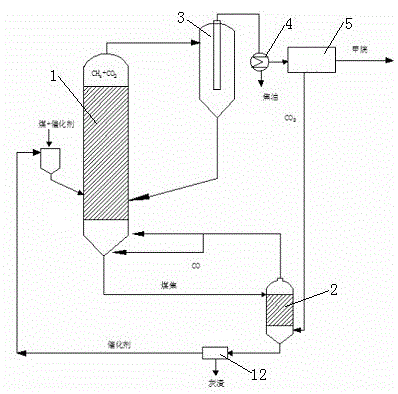

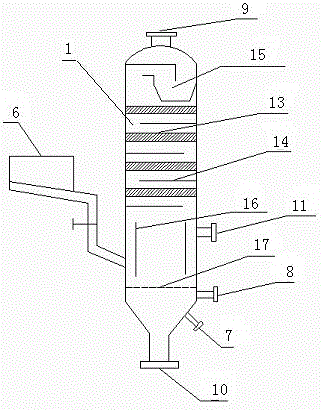

[0041] like figure 1 As shown, a lignite catalyzed direct methane production device is characterized in that it includes a reaction furnace 1, a carbon monoxide generation furnace 2, a gas-solid separator 3, a condenser 4, and a gas purification separator 5; Side is provided with coal, catalyst inlet 6, and right side is provided with carbon monoxide gas inlet, and described carbon monoxide gas inlet is made up of first inlet 7 and second inlet 8, and first inlet 7 is arranged upward along the bottom center of reaction furnace, and second inlet 8 is set upward at an angle of 30-70 degrees to the axial direction of the reaction furnace; the top of the reaction furnace is provided with a synthesis gas outlet 9, and the bottom is provided with a coal char outlet 10, the synthesis gas outlet 9 is connected to the gas-solid separator, and the top of the gas-solid separator 3 is connected to the condensation 4, the other end of the condenser 4 is connected to the gas purification se...

Embodiment 2

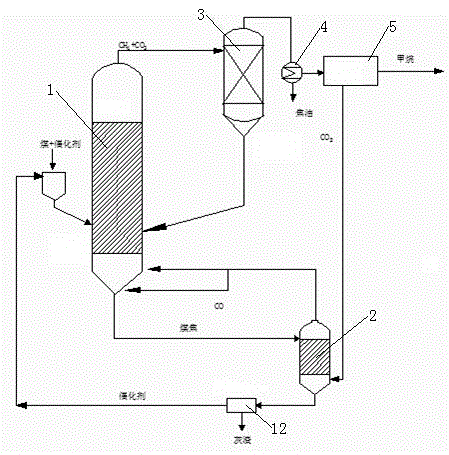

[0060] The present invention provides another preferred embodiment, see figure 2 .

[0061] General reaction device layout and reaction furnace structure concrete embodiment 1 of the present invention, the difference is that in this embodiment, the gas-solid separator is a particle moving bed dust collector; further, the particle moving bed dust collector adopts synthetic Gas methanation catalysts act as dust removal particles to generate higher levels of methane gas.

[0062] After the methane-containing gas products generated in the reactor leave the reactor, they can also enter the particle moving bed for gas-solid separation, such as image 3 As shown, the separated solids can be used for other purposes, or returned to the gasifier for reuse, wherein the synthetic gas methanation catalyst is used as dust removal particles in the particle moving bed, the advantage of this is that the reaction is not complete The synthesis gas can also continue to react here to generate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com