Recombinant Escherichia coli for expressing arginine deiminase gene and application of recombinant Escherichia coli

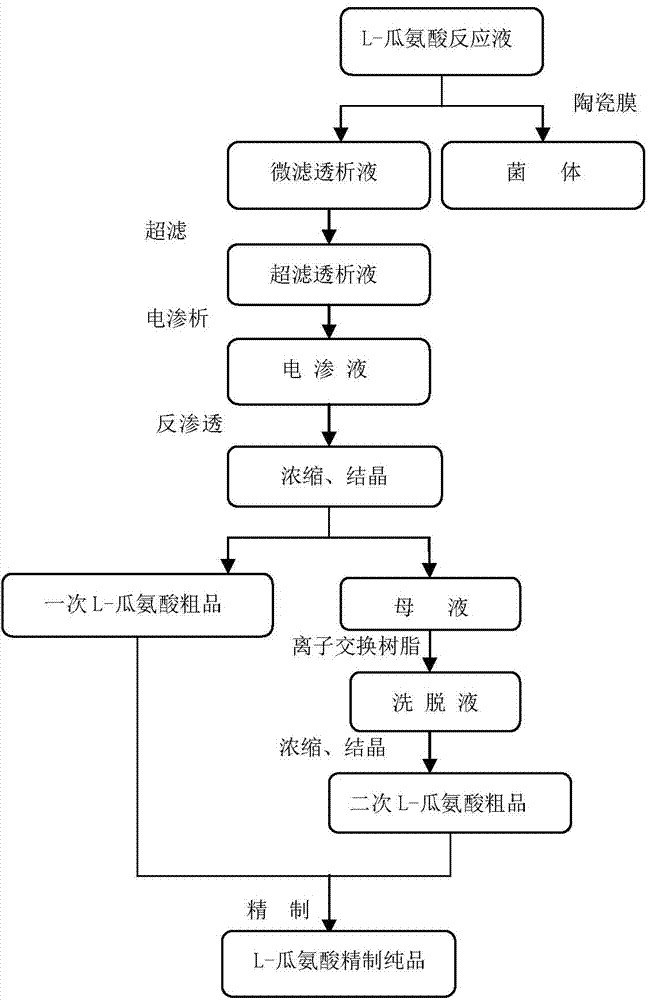

An arginine deiminase, recombinant Escherichia coli technology, applied in the application, genetic engineering, plant genetic improvement and other directions, can solve the problem of poor temperature tolerance (transformation temperature can only be controlled around 37 ℃, unfavorable separation and purification, wet The problem of high amount of bacterial cells can shorten the transformation time, shorten the production cycle and reduce the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The acquisition of embodiment 1 bacillus cereus mutant strain

[0038] 1. Preparation of Type-Based Strains

[0039] Take a strain of Bacillus cereus obtained from the soil as the starting strain, insert it into a medium containing 100ml, cultivate it at 30-37°C, 100-200r / min for 5-30h, then take 1ml of the bacterial solution and add it to 9ml of sterile water, mix well, dilute the concentration to 10 times, continue to dilute 10 times in this way -2 , 10 -3 and 10 -4 times, and the bacterial solution is set aside.

[0040] The composition of the culture medium is: 0.1-10% peptone, 0.1-5% yeast powder, 0.1-10% sodium chloride, the balance is deionized water, and the pH is 6.0-7.5.

[0041] 2. N ion beam mutagenesis

[0042] Take 0.5ml of the bacterial solution prepared in step 1, apply it to a sterile petri dish and dry it, and use a TITAN ion beam implanter to perform N ion beam implantation on the bacteria with an energy of 30keV and an injection dose of 1-5×10 ...

Embodiment 2

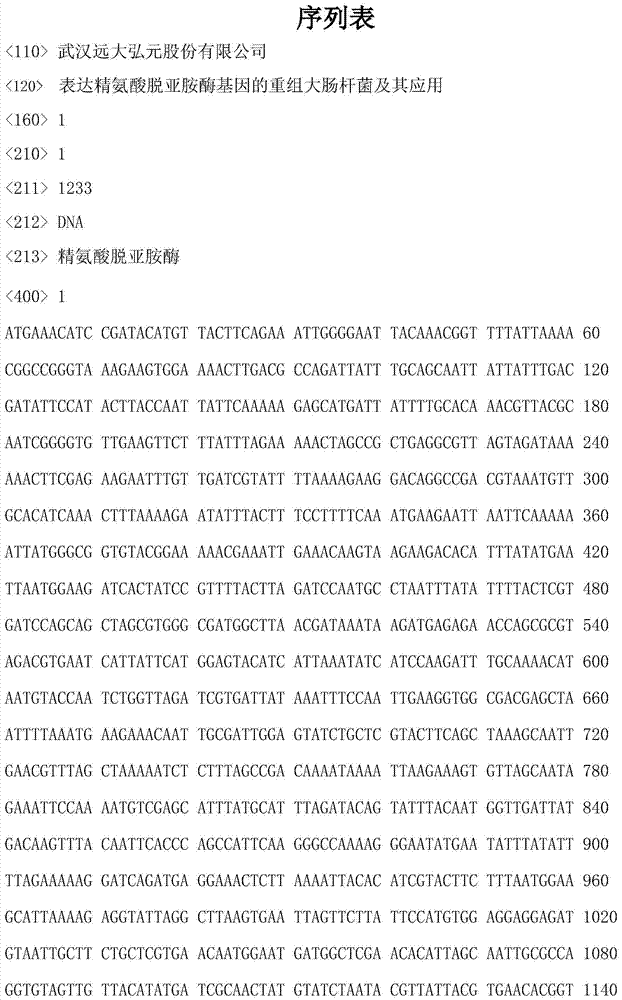

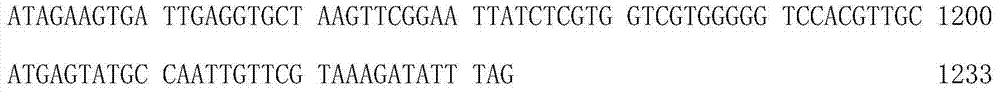

[0052] Example 2 Genome Extraction, Target Fragment Amplification and Genetic Engineering Bacteria Construction

[0053] 1. Reagents and materials: Escherichia coli DH5α, BL21, pMD19-T simple vector, and pET28a vectors are all preserved by our laboratory.

[0054] Experimental reagents: DNA polymerase (KOD DNA Polymerase) was purchased from TOYOBO; restriction enzymes (EcoRI and NotI), T4DNA Ligase, dNTPs, DNA marker DL2,000, plasmid mini-extraction kit, and DNA purification kit were purchased from From Takara Corporation. Bacterial genome extraction kits were purchased from Tiangen Company, ampicillin, kanamycin sulfate, and IPTG were purchased from Biosharp Company, and other chemical reagents were of analytical grade.

[0055] 2. Extraction of Bacillus cereus genomic DNA

[0056] Select a single colony of Bacillus cereus 93-11 with the preservation number CCTCC NO: M 2015047 and inoculate it into 1-4ml of LB liquid medium for overnight culture; take 1-4ml of the overnight...

Embodiment 3

[0069] The fermentation culture of embodiment 3 recombinant bacteria

[0070] 1. Seed culture:

[0071] Put the engineered bacteria preserved in glycerin into a 250ml eggplant bottle LB solid slope and cultivate for 16-24h, then wash it down with sterile water, and take about 25ml and put it into the seed medium.

[0072] Seed medium: corn steep liquor 2-10%, monosodium glutamate 1-10%, MgSO 4 0.01-0.1%, KH 2 PO 4 0.01-0.1%, pH 4.0-7.5, prepared with deionized water;

[0073] Seed culture conditions: the strain is cultured in the seed medium for 5-30 hours at 30-37°C and a shaking speed of 100-300rpm to obtain seed bacteria;

[0074] 2. Fermentation culture

[0075] Fermentation medium: corn steep liquor 3-15%, monosodium glutamate 2-12%, MgSO 4 0.01-0.1%, KH 2 PO 4 0.01-0.1%, pH 4.0-7.5, prepared with deionized water;

[0076] Fermentation conditions: 1-10% inoculum size, 30-37°C, 150-450rpm rotation speed, culture in the fermentation medium for 0.5-4h, add lactose w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com