Polymer metal binder containing 3,4-dihydropyrimidin-2-one structure and its preparation method and application

A technology of dihydropyrimidine and adhesives, which is applied in the field of polymer metal adhesives and their preparation, can solve the problems of difficult storage and low temperature tolerance during curing time, and achieve good bonding effect and satisfactory adhesion. It takes a short time to achieve the effect of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1, preparation of polymer metal binder containing 3,4-dihydropyrimidin-2-one structure:

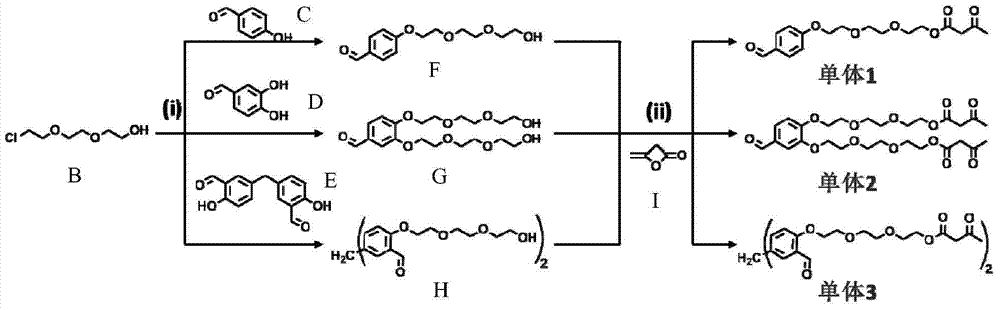

[0036] 1) According to figure 1 The synthetic route diagram in prepares monomer 1, monomer 2 and monomer 3 containing aldehyde group and β-diketone structure, concrete steps are as follows: under potassium carbonate and sodium iodide effect (make the mole of potassium carbonate and compound B Ratio is 2:1.1, makes the mol ratio of sodium iodide and compound B be 1:1.1), compound B and compound C, compound D or compound E are 1.1:1 in organic solvent N,N-two The reaction was carried out in methylamide, the reaction temperature was 110°C, and the reaction time was 8h;

[0037] Then, under the action of triethylamine (making the molar ratio of triethylamine and compound I be 2:1.1), the obtained compound F, compound G or compound H is respectively mixed with compound I in a molar ratio of 1:1.1. In the organic solvent dichloromethane, heated to reflux at 40°C for 6h to obtai...

Embodiment 2

[0039] Example 2, preparation of a polymer metal binder containing 3,4-dihydropyrimidin-2-one structure:

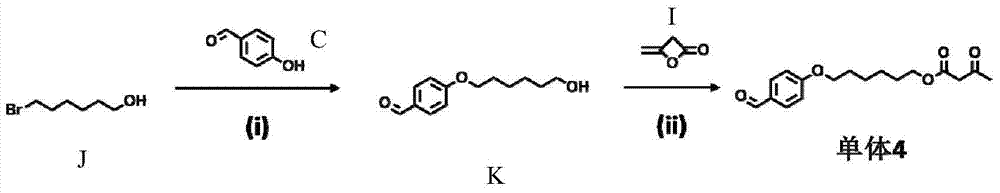

[0040] 1) According to image 3 The synthetic route diagram in prepares the monomer 4 that contains aldehyde group and β-diketone structure, concrete steps are as follows: under the effect of potassium carbonate and sodium iodide (make the mol ratio of potassium carbonate and compound B be 2:1.1, make iodine The molar ratio of sodium chloride and compound B is 1:1.1), compound J and compound C are reacted in the organic solvent N,N-dimethylamide at a molar ratio of 1.1:1, and the reaction temperature is 110°C. The time is 8h;

[0041] Then, under the action of triethylamine (making the mol ratio of triethylamine and compound I be 2:1.1), the obtained compound K and compound I are in the organic solvent dichloromethane in the molar ratio of 1:1.1, Heat to reflux at 40°C for 6h to obtain monomer 4;

[0042] 2) The monomer 4 obtained in step 1) and 0.125mmol / L aqueous ure...

Embodiment 3

[0043] Embodiment 3, bonding experiment between metal materials:

[0044] 1) Dissolve 1.2g of urea in water, and obtain 3mL urea 0.125mmol / L aqueous solution at constant volume;

[0045] 2) Drop 37 μL of urea aqueous solution on the surface of the metal sheet in a 1cm×1cm area, and volatilize to form a film;

[0046] 3) Drop about 40 mg of monomer 1, monomer 2, monomer 3 or monomer 4 obtained in step 1) of Example 1 on the film, and press the two metal sheets tightly;

[0047] 4) Heat the two compressed metal sheets at 130°C for 20 minutes, take them out and cool to room temperature, and then bond the two metal sheets together;

[0048] Tensile test: The multi-function digital testing machine controlled by the computer is used to test the bond shear strength:

[0049]The polymer metal adhesive containing 3,4-dihydropyrimidin-2-one structure obtained from monomer 1 has an adhesive strength of 1.2 MPa to aluminum sheets, 1.4 MPa to stainless steel sheets, and 1.4 MPa to copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com