Water-soluble polyurethane flame-retardant coating and preparation method thereof

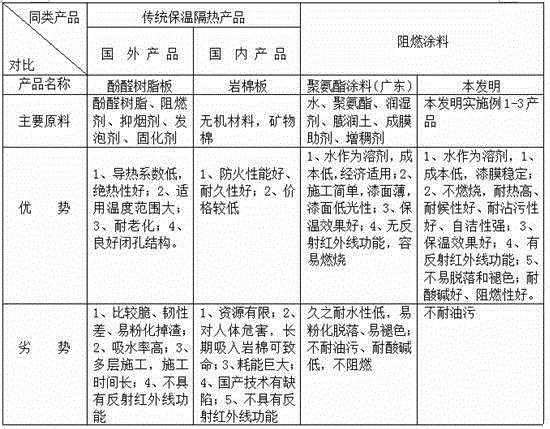

A water-soluble polyurethane and flame retardant coating technology, applied in polyurea/polyurethane coatings, antifouling/underwater coatings, anti-corrosion coatings, etc. Thickness ratio and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

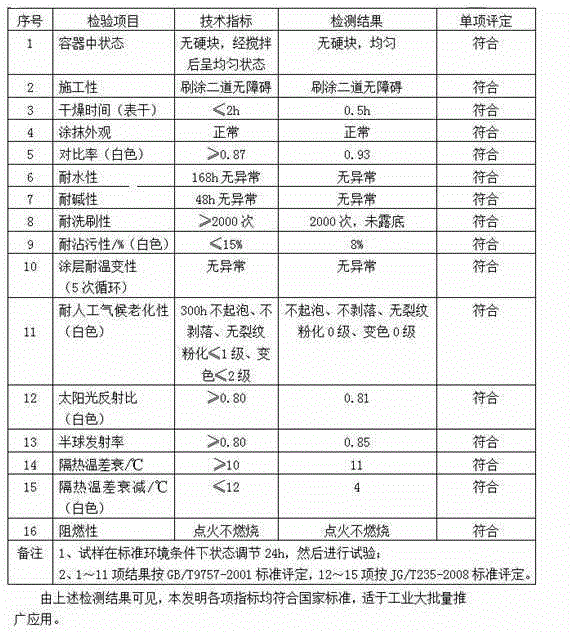

Examples

Embodiment 1

[0046] First, 40 parts of polyurethane prepolymer, 1 part of N-methylolacrylamide, 2 parts of dibutyl phthalate, 0.5 parts of monoalkoxy pyrophosphate titanate coupling agent, 3 parts of talc powder with product number TL75-45-98GB, 3 parts of light calcium carbonate (micronized calcium carbonate with average particle size d=1-5μm), 0.1 part of tributyl phosphate, 0.5 part of isopropanol; mixed solvent 10 parts (mixture of lignin and ethylene glycol butyl ether plus water, the weight ratio is 3:1:10), 3 parts of flame retardant materials (the mixture of sericite powder and brominated flame retardant plus antimony trioxide, the weight ratio 10:2:1), 1 part of leveling agent polyacrylate solution, 2 parts of iron oxide yellow; prepare materials.

[0047] The production method is to add 2 kilograms of ethanol with a volume concentration of 50-70% per kilogram of N-methylolacrylamide to dissolve, and then mix it with polyurethane prepolymer in a reaction kettle. The reaction temp...

Embodiment 2

[0049] First, 45 parts of polyurethane prepolymer, 1.5 parts of N-methylolacrylamide, 3 parts of dibutyl phthalate, 0.7 parts of monoalkoxy pyrophosphate titanate coupling agent, 5 parts of talcum powder with product number TL75-45-98GB, 6 parts of light calcium carbonate (micronized calcium carbonate with average particle size d=1-5 μm), 0.2 part of tributyl phosphate, 0.7 part of isopropanol; mixed solvent 13 parts (a mixture of lignin and ethylene glycol butyl ether plus water, the weight ratio is 3:1:10), 5 parts of flame retardant materials (a mixture of sericite powder and brominated flame retardant plus antimony trioxide, the weight ratio 10:2:1), 1 part of N-methylpyrrolidone solution of polyurea modified by anti-settling agent, for material preparation.

[0050] The production method is to add 2 kilograms of ethanol with a volume concentration of 50-70% per kilogram of N-methylolacrylamide to dissolve, and then mix it with polyurethane prepolymer in a reaction kettl...

Embodiment 3

[0052] First, 50 parts of polyurethane prepolymer, 2 parts of N-methylolacrylamide, 5 parts of dibutyl phthalate, 1 part of monoalkoxypyrophosphate titanate coupling agent, 8 parts of talcum powder with product number TL75-45-98GB, 10 parts of light calcium carbonate (micronized calcium carbonate with average particle size d=1-5 μm), 0.3 parts of tributyl phosphate, 1 part of isopropanol; mixed solvent 15 parts (a mixture of lignin and ethylene glycol butyl ether plus water, the weight ratio is 3:1:10), 8 parts of flame retardant materials (a mixture of sericite powder and brominated flame retardant plus antimony trioxide, the weight ratio 10:2:1), 1 part of antifreeze 1,3-propanediol, 1 part of iron oxide red, and prepare materials.

[0053] The production method is to add 2 kilograms of ethanol with a volume concentration of 50-70% per kilogram of N-methylolacrylamide to dissolve, and then mix it with polyurethane prepolymer in a reaction kettle. The reaction temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com