Polymer lithium-sulfur battery and preparation method thereof

A lithium-sulfur battery and polymer technology, applied in lithium batteries, secondary batteries, battery electrodes, etc., can solve the problems of complex preparation process, low conductivity, poor interface compatibility, etc., and achieve high energy density and safety performance. The effect of high and low polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

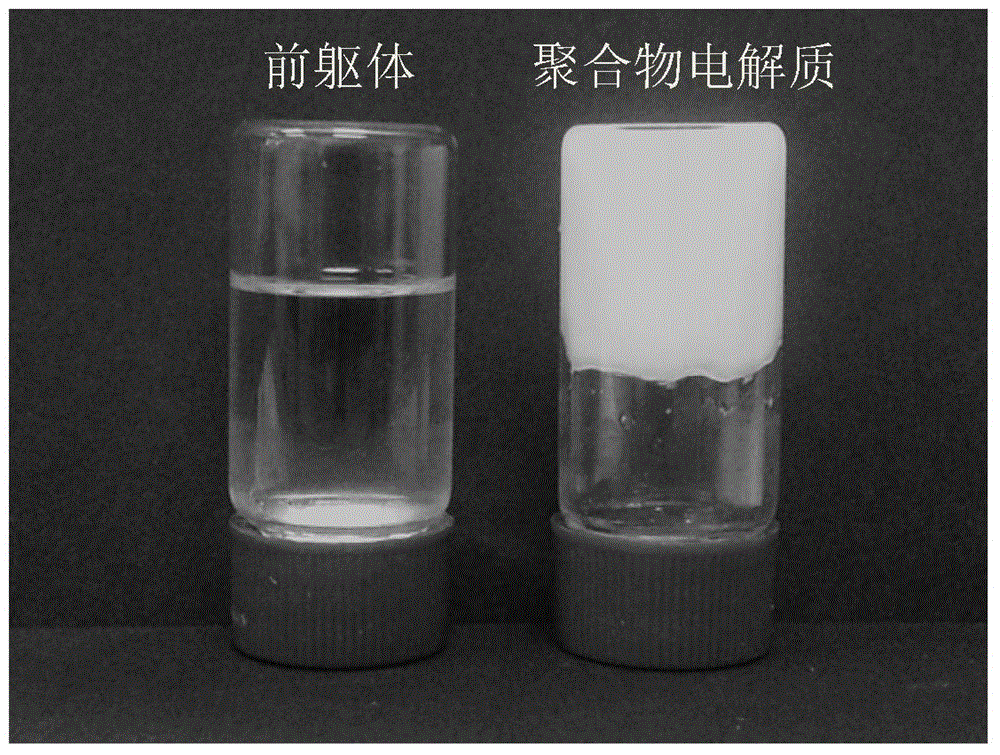

[0031] Step 1) take by weighing the following components according to the following mass relation, by weight, ethoxylated pentaerythritol tetraacrylate: ethylene carbonate: diethyl carbonate: ethyl methyl carbonate: lithium hexafluorophosphate: lauroyl peroxide=5:30:20 :30:14.9:0.1. Ethylene carbonate, diethyl carbonate and ethyl methyl carbonate are mixed uniformly, then lithium hexafluorophosphate is added, and ethoxylated pentaerythritol tetraacrylate and lauroyl peroxide are added to the above electrolyte to obtain a polymer electrolyte precursor;

[0032] Step 2) Prepare the battery cell to be injected: according to the weight ratio, the ratio of nano-sulfur powder: acetylene black: polyvinylidene fluoride is 70:25:5 to weigh the positive electrode material; according to the weight ratio, lithium intercalation graphite: acetylene black : The ratio of polyvinylidene fluoride is 90:5:5. Weigh the negative pole piece material. After stirring, coating, cold pressing, slitting...

Embodiment 2

[0035] Step 1) take by weighing the following components according to the following mass relationship, according to weight ratio, dipentaerythritol hexaacrylate: ethylene glycol dimethyl ether: 1,3-dioxolane: base two (trifluoromethanesulfonic acid) sulfite Lithium amide: azobisisobutyronitrile = 3:40:40:30:14.9:0.1. Mix ethylene glycol dimethyl ether and 1,3-dioxolane evenly, then add lithium bis(trifluoromethanesulfonic acid)imide, and then add bispentaerythritol hexaacrylate and azobisisobutyronitrile. The above-mentioned electrolyte solution prepares a polymer electrolyte precursor;

[0036] Step 2) Prepare the battery cell to be injected: according to the weight ratio, the ratio of sulfur-carbon composite material: carbon nanotube: polytetrafluoroethylene is 70: 25: 5 to weigh the positive electrode material, after stirring, coating, cold pressing , slitting, welding and other processes to obtain the pole piece to be wound, and then winding it together with the isolation...

Embodiment 3

[0039] Step 1) Weigh the following components according to the following mass relationship, and according to the weight ratio, succinonitrile: acrylonitrile substituted polyvinyl alcohol: lithium hexafluorophosphate: boron trifluoride=75:10:14.9:0.1. heating and melting succinonitrile at 50°C, adding acrylonitrile to replace polyvinyl alcohol, lithium hexafluorophosphate and boron trifluoride into the nitrile melt and mixing them evenly to obtain an all-solid polymer electrolyte precursor;

[0040] Step 2) Preparation of the battery cell to be injected: according to the ratio of organic sulfide: graphene: sodium carboxymethyl cellulose to 70:25:5, weigh the positive electrode material; according to the lithium-inserted silicon-carbon composite material: graphene: Sodium carboxymethyl cellulose is weighed in the ratio of 90:5:5, and the negative electrode pole piece material is mixed to obtain the pole piece to be wound through the processes of stirring, coating, cold pressing, sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Coulombic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com