Method for liquid-phase synthesis of nano spherical lithium battery anode material lithium iron phosphate

A positive electrode material, lithium iron phosphate technology, applied in the direction of phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high requirements for synthesis equipment, unfavorable industrial production, large particle size of products, etc. Conditions and experimental equipment requirements are low, the effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

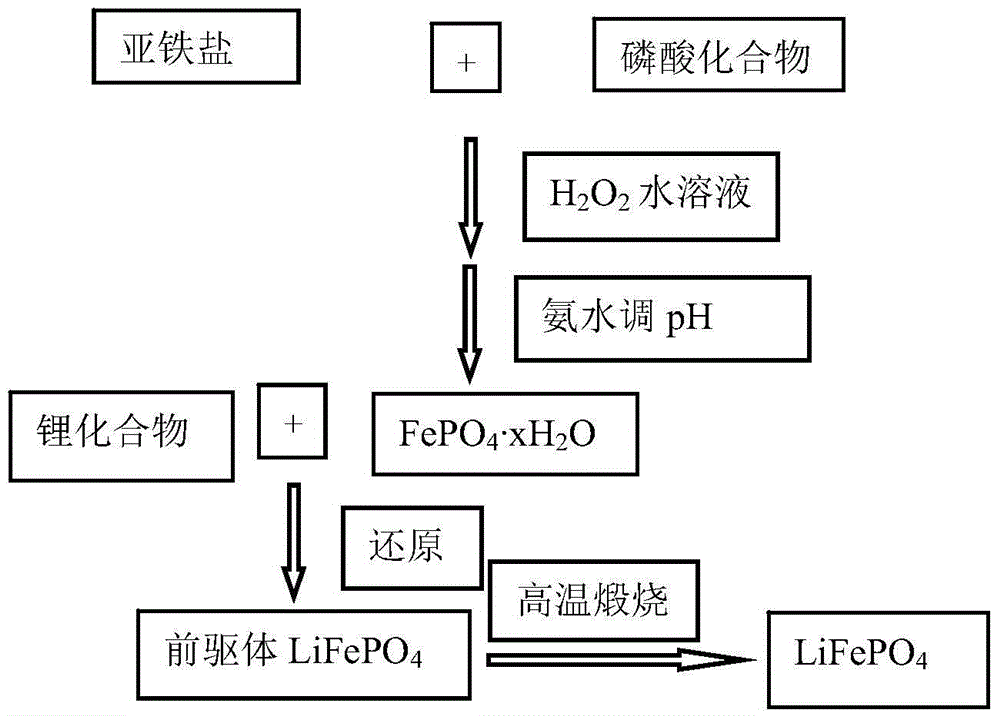

[0038] A nano-spherical lithium battery cathode material LiFePO 4 The method for liquid-phase method synthesis, comprises the steps:

[0039] (1) FePO 4 2H 2 Preparation of O: Weigh 27.4g FeSO 4 ·7H 2 O and 11.5gNH 4 h 2 PO 4 (Fe / P molar ratio is 1:1) respectively dissolved in distilled water to make 1mol L -1 solution, mix the two solutions evenly under stirring, add 20mg polyvinyl alcohol, drop 7.34g H 2 o 2 Aqueous solution (mass concentration is 30%, Fe / H 2 o 2 The molar ratio is 1:0.6), with NH 3 ·H 2 O adjusts the pH to 2, particles are generated, and filtered to obtain filtrate 1 and particle 1, and particle 1 is washed with distilled water until it is washed with Ba(OH) 2 Solution detects no SO in the washed filtrate4 2- , dried at 80°C to obtain FePO 4 2H 2 0; 20mg polyvinyl alcohol can make the particles generated in the reaction solution uniformly dispersed and uniform in appearance;

[0040] (2) LiFePO 4 Preparation: Weigh 3.78g FePO 4 2H 2 O an...

Embodiment 2

[0050] A nano-spherical lithium battery cathode material LiFePO 4 The method for liquid-phase method synthesis, comprises the steps:

[0051] (1) FePO 4 2H 2 Preparation of O:

[0052] Adopt the filtrate 1 that embodiment 1 step (1) obtains to replace the dissolved FeSO in embodiment 1 step (1) 4 and NH 4 h 2 PO 4 The amount of distilled water used is not enough to make up with distilled water, and others obtain FePO with embodiment 1 step (1). 4 2H 2 O, called step (1) cycle 1 time, denoted as #A, similarly, recycle 2, 3, 4, 5 times of filtrate 1 to prepare FePO 4 2H 2 O, recorded as #B, #C, #D, #E in turn.

[0053] (2) with embodiment 1 step (2);

[0054] (3) Characterization of the product: see the discharge curve of the product Figure 6 .

Embodiment 3

[0056] A nano-spherical lithium battery cathode material LiFePO 4 The method for liquid-phase method synthesis, comprises the steps:

[0057] (1) FePO 4 2H 2 The preparation of O: with embodiment 1 step (1);

[0058] (2) Use the filtrate 2 obtained in Example 1 step (2) to replace the ethanol in Example 1 step (2) as a solvent, the amount is not enough to make up with absolute ethanol, and the others are the same as Example 1 step (2) to obtain LiFePO 4 , which is called step (2) cycle 1 time, denoted as #1, similarly, the filtrate 2 is recycled twice to obtain LiFePO 4 , denoted as #2.

[0059] (3) Characterization of the product: see the discharge curve of the product Figure 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com