Mesoporous bioactive glass/lasiosphaera composite material, preparation and applications

A technology of bioactive glass and composite materials, which is applied in the fields of hemostatic and antibacterial materials and their preparation, can solve the problems of mesoporous molecular sieves and mesoporous silicon-based xerogels with low biological activity, poor hydrophilicity, and poor hemostasis, etc., and achieve good Bioactivity and biocompatibility, low cost, infection prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

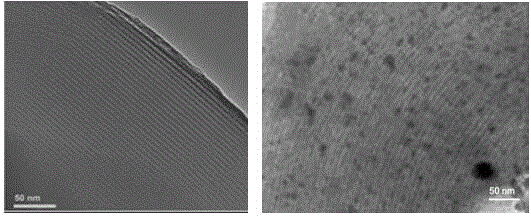

[0047] Dissolve 10g of surfactant P123 in 500ml of deionized water, stir magnetically at 38°C until clear, adjust the pH to less than 1 with hydrochloric acid, then add 200g of tetraethyl orthosilicate (TEOS), stir until the solution is clear, Fully hydrolyze the silicon source, then magnetically stir in a water bath at 60°C for 48 hours to obtain a sol-gel white solution, leave it for 6 hours to remove the supernatant, and then dry it in an oven at 100°C for 36 hours. A dry powder was obtained. The dried powder was raised to 700°C at a heating rate of 1°C / min in a muffle furnace, and sintered for 8 hours to obtain a mesoporous bioglass powder. The particle size of mesoporous glass is 7-15um, and the pore size is 6-20nm. SEM photos show that the resulting mesoporous bioactive glass has a regular and ordered mesoporous nanopore structure, such as figure 1 shown.

Embodiment 2

[0049] Dissolve 10g of surfactant P123 in 500ml of deionized water, stir magnetically at 35~45°C until clarified, adjust the pH value to less than 1 with hydrochloric acid, and then add silicon source, phosphorus source and calcium source in sequence One or more, according to the molar ratio of silicon dioxide and other oxides (100-50): (0-50) to react and add, continue to stir and dissolve completely, then magnetically stir in a water bath at 60°C for 48 hours to obtain a sol-gel Colloidal white solution, after standing for 6 hours to remove the supernatant, dry in an oven at 100°C for 24-48 hours. A dry powder was obtained. The dried powder is raised to 550-700° C. in a sintering furnace at a heating rate of 1° C. / min, and sintered for 6 hours to obtain a mesoporous bioglass powder. The particle size of mesoporous glass is 0.3-15um, and the pore size is 2-20nm.

Embodiment 3

[0051] Dissolve 10g of surfactant P123 in 500ml of deionized water, stir magnetically at 45°C until clarification, adjust the pH value to less than 1 with hydrochloric acid, then add silicon source, phosphorus source and calcium source in sequence, according to the silica React with other oxides at a molar ratio of 1:1. After completely dissolving, heat and stir in a constant temperature water bath at 33-36°C for 48 hours to obtain a white sol liquid. Put the beaker containing the white sol solution at a constant temperature of 100°C Stand in an oven for 24 hours, and dry to obtain a dry powder. The dried powder was raised to 550° C. in a sintering furnace at a heating rate of 1° C. / min, and sintered for 4 hours to obtain a mesoporous bioglass powder. The particle size of mesoporous glass is 0.3-12um, and the pore size is 2-16nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com