Cement-based polymer waterproof mortar additive and its preparation method and application

A polymer-based, waterproof mortar technology, applied in the field of building materials, can solve the problems of water-soluble migration, concrete spalling, unstable quality, etc., and achieve the effect of improving the adsorption and bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

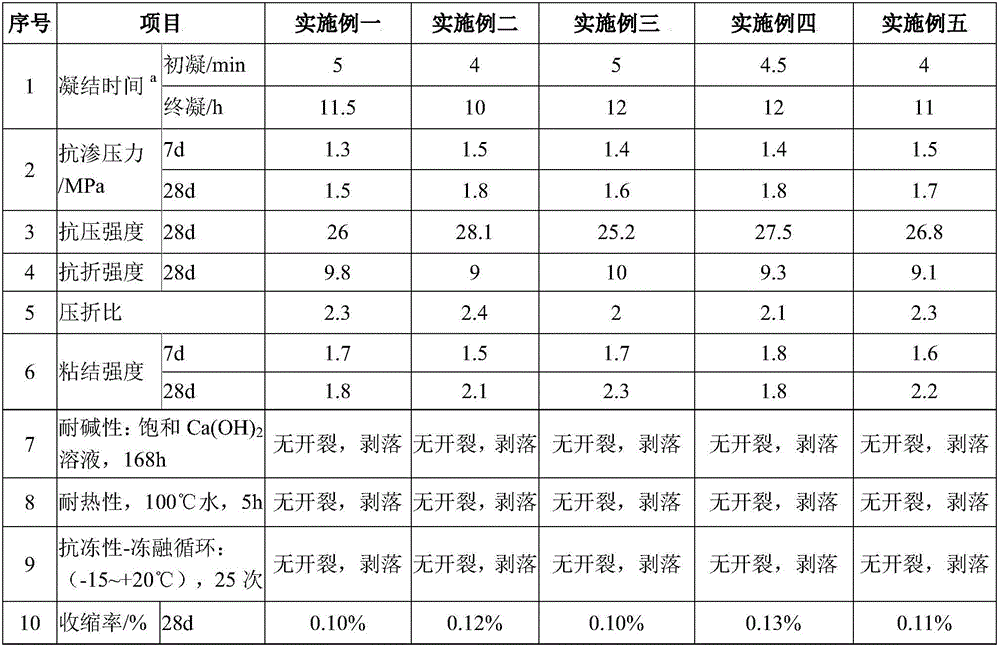

Examples

Embodiment 1

[0047] The invention provides a cement-based polymer waterproof mortar additive, which is made of the following raw materials in parts by weight: 1 part of ethylene-vinyl acetate redispersible latex powder; 5 parts of polypropylene fiber; 2 parts of polyaspartic acid 6 parts of cerium oxide; 2 parts of attapulgite; 5 parts of sodium polyacrylate; 10 parts of fly ash, 8 parts of heavy calcium carbonate, 0.2 parts of sulfonated melamine superplasticizer, 0.8 parts of silicone defoamer, 0.6 parts of cellulose ether.

[0048] The present invention also provides a method for preparing a cement-based polymer waterproof mortar additive, specifically comprising the following steps:

[0049] 1) Put the attapulgite in phosphoric acid with a mass fraction of 50% for 10 hours, then roast it in a high-temperature resistance furnace at a temperature of 400°C for 1.8 hours; then boil it with 0.1mol / L hydrochloric acid solution for 10 minutes, and wash it with distilled water To neutrality; ...

Embodiment 2

[0056] The invention provides a cement-based polymer waterproof mortar additive, which is made of the following raw materials in parts by weight: 6 parts of ethylene-vinyl acetate redispersible latex powder; 10 parts of polyacrylonitrile fiber; polyaspartic acid 5 parts; 12 parts of cerium oxide; 6 parts of attapulgite; 8 parts of sodium polyacrylate; 20 parts of fly ash, 10 parts of heavy calcium carbonate, 0.6 parts of polycarboxylate water reducer, 1.2 parts of silicone defoamer, 0.8 parts of cellulose ether.

[0057] The present invention also provides a method for preparing a cement-based polymer waterproof mortar additive, specifically comprising the following steps:

[0058] 1) After the attapulgite was left to stand in phosphoric acid with a mass fraction of 50% for 12 hours, it was roasted for 2 hours at a temperature of 450°C in a high-temperature resistance furnace; then it was boiled with 0.1mol / L hydrochloric acid solution for 15 minutes, and washed with distilled...

Embodiment 3

[0065] The invention provides a cement-based polymer waterproof mortar additive, which is made of the following raw materials in parts by weight: 3 parts of ethylene-vinyl acetate redispersible latex powder; 5 parts of polypropylene fiber; 5 parts of polyaspartic acid 7 parts of cerium oxide; 5 parts of attapulgite; 7 parts of sodium polyacrylate; 16 parts of fly ash, 8 parts of heavy calcium carbonate, 0.5 parts of sulfonated melamine superplasticizer, 0.9 parts of silicone defoamer, 0.8 parts of cellulose ether.

[0066] The present invention also provides a method for preparing a cement-based polymer waterproof mortar additive, specifically comprising the following steps:

[0067] 1) Put the attapulgite in phosphoric acid with a mass fraction of 50% for 11 hours, then roast it in a high-temperature resistance furnace at a temperature of 430°C for 1.9 hours; then boil it with 0.1mol / L hydrochloric acid solution for 12 minutes, and wash it with distilled water To neutrality;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com