Biological chemistry-thermochemistry multi-point crosslinking biomass waste processing method and system

A biomass waste and biochemical technology, applied in the field of biochemical-thermochemical multi-point cross-linking treatment of biomass waste, can solve the problems of low solid-liquid separation efficiency, easy corruption, low competitiveness, etc., and achieve shortening of anaerobic Effect of reaction time, accelerated methane production rate, reduction of pollution and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

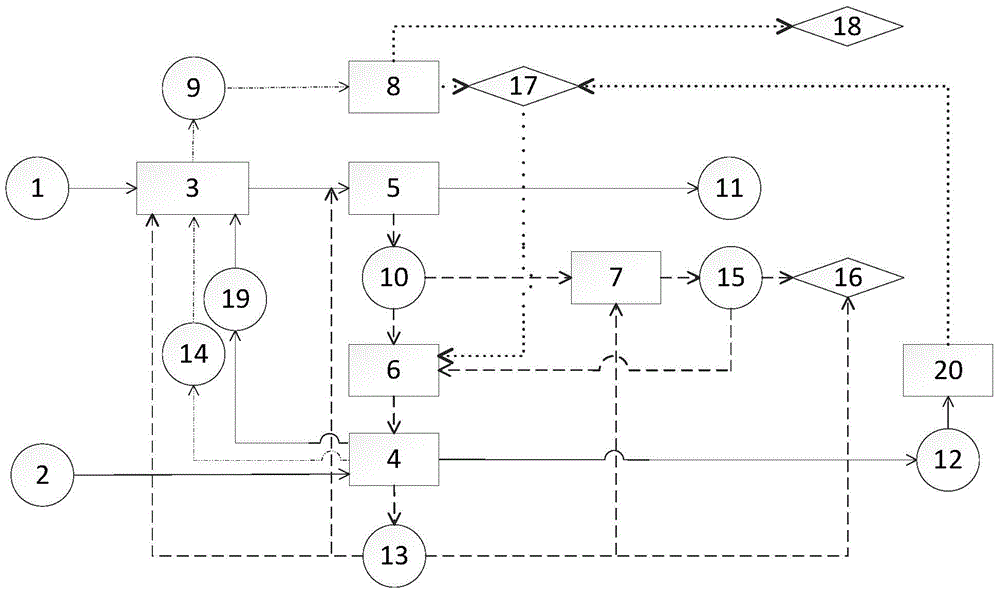

[0039] Biochemical-thermochemical multi-point cross-linking method for treating biomass waste, using figure 1 The process shown, the realization of this method comprises the following steps: (1) dry biomass waste 2 is converted into pyrolysis gas 14, biochar 13, pyrolysis oil 12, water phase condensate 19 through pyrolysis unit 4; (2) Pyrolysis gas 14 and water phase condensate 19 enter the anaerobic digestion unit 3 for processing wet biomass waste 1; (3) biochar 13 enters the anaerobic digestion unit 3, and enters the solid-liquid separation unit 5 along with the digestion residue (4) The digested residue is divided into biogas slurry 11 and biogas residue 10 through the solid-liquid separation unit 5, and biochar 13 can be added before the solid-liquid separation unit 5; (5) The biogas residue 10 is post-processed in the composting unit 7 , forming a compost product 15, which can be used as a soil conditioner 16; biochar 13 can be replenished in the composting unit 7; (6) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com