Preparation method and device of high-purity lithium sulfide

A technology of lithium sulfide and lithium sulfide hydride, applied in the field of chemistry, can solve the problems of irritation and toxicity, flammable and explosive organic solvents, high reaction temperature, high product yield and purity, direct and simple purification process, and high reaction temperature. low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

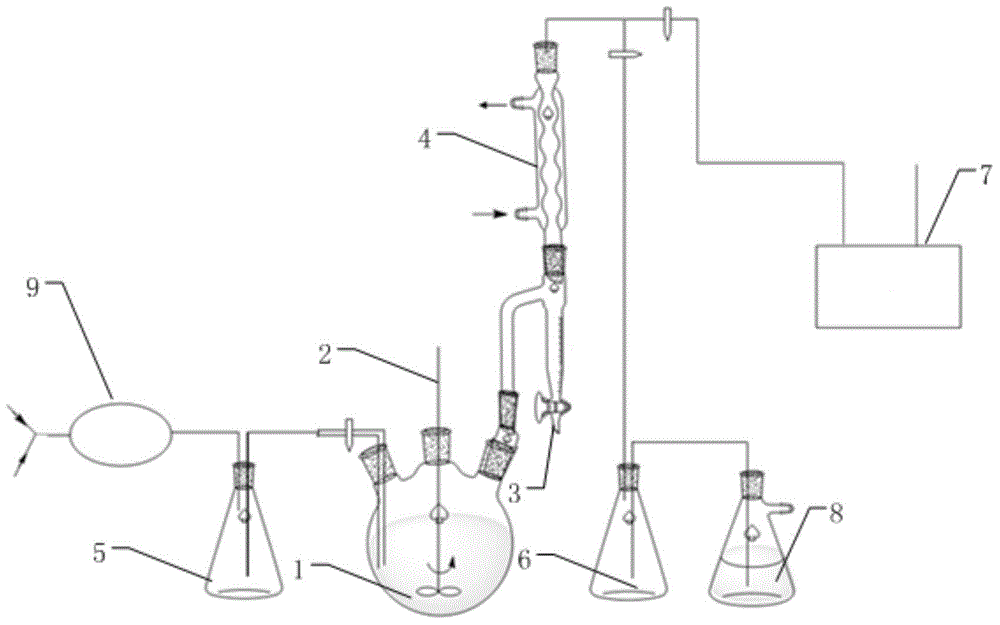

Image

Examples

preparation example Construction

[0043] The invention provides a method for preparing high-purity lithium sulfide, comprising:

[0044] Purify lithium hydroxide, the purification temperature is 110-120°C, and the purification time is 3-4h; mix lithium hydroxide with N-methylpyrrolidone to obtain a mixed solution; heat the mixed solution to 130°C under the protection of an inert gas -140°C, the inert gas can be argon or nitrogen, and the flow rate of the inert gas is 0.15~0.25m 3 / h, while heating, start stirring, the stirring time is 2 to 3 hours, and the stirring speed is 150 to 250 rpm; hydrogen sulfide gas is passed into the mixed solution, and the reaction time is 2 to 4 hours to obtain Lithium hydrogen sulfide slurry; remove hydrogen sulfide from lithium hydrogen sulfide by high temperature method, and remove hydrogen sulfide at a temperature of 170-180°C to obtain lithium sulfide slurry; remove excess hydrogen sulfide gas by purging with inert gas , the purging process lasts for 2 to 3 hours; the lithi...

Embodiment 1

[0055] Take 500g of lithium hydroxide monohydrate in a 5L round-bottomed flask and dehydrate under reduced pressure at 120°C for 3 hours to remove the crystal water and purify the lithium hydroxide. After cooling down, add 3.5L N-methylpyrrolidone, vacuumize, and purge the system with argon gas, the flow rate is 0.15m 3 / h, after repeating this three times, the temperature was raised to 140°C, mechanically stirred for 3h, and the stirring speed was 160 rpm. Introduce hydrogen sulfide gas, react at the above temperature and stir for 4h. After that, stop passing hydrogen sulfide, raise the temperature to 180°C, react for 2 hours, remove hydrogen sulfide to generate lithium sulfide, and then purge with argon to remove excess hydrogen sulfide gas, and the purge process lasts for 2 hours. The reaction slurry was centrifuged at a centrifugal speed of 7000 rpm and a centrifugation time of 0.5h. The centrifuged precipitate was redissolved in 500ml of N-methylpyrrolidone and refluxed ...

Embodiment 2

[0058] Take 500g of lithium hydroxide monohydrate in a 5L round-bottomed flask and distill and dehydrate under reduced pressure at 120°C to remove crystal water. After cooling down, add 4 LNMP, vacuumize, and purge the system with argon gas. After repeating this three times, the temperature is raised to 140° C., and mechanically stirred for 3 hours. Introduce hydrogen sulfide gas and react at the above temperature for 2h with stirring. After that, the flow of hydrogen sulfide was stopped, and the temperature was raised to 190°C to remove hydrogen sulfide and generate lithium sulfide. After the reaction slurry was centrifuged, the centrifuged precipitate was redissolved in 300ml of NMP, refluxed at 150°C for 2 hours, filtered and dried while hot to obtain 246.10g of high-purity lithium sulfide. The centrifugal liquid is decolorized by vacuum distillation to recover NMP and can be reused.

[0059] Take 500g of lithium hydroxide monohydrate in a 5L round-bottomed flask and dehy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com