Copper ore processing technology

A processing process and technology for copper ore, applied in the field of processing technology of copper ore, can solve the problems of unfavorable copper extraction, unfavorable copper extraction in ammonium salt solution, large dissolution loss of extractant, etc., so as to shorten the leaching time and selectivity Strong, improve the effect of leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

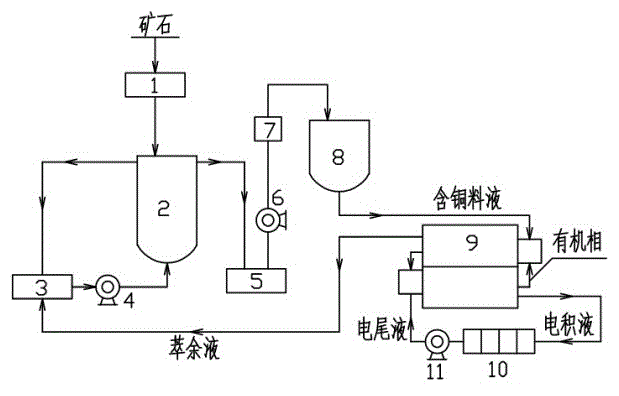

Embodiment 1

[0069] The newly mined oxygen-sulfur mixed ore was selected and analyzed by non-ferrous geological tests: total copper: 1.8%, primary copper sulfide: 0.128%, secondary copper sulfide: 0.488%, free copper oxide: 1.12%, combined copper oxide: 0.064%, Vulcanization rate: 34.22%, oxidation rate: 65.78%, binding rate: 3.56%, after the mixed ore is crushed by sand making machine 1 with 6mm mesh, the particle size distribution is: <40 mesh accounts for 17%, 40 mesh -3mm accounts for 33%, 3-6mm accounts for 50%, put the crushed ore into the leaching tank 2, add the leaching agent in the leaching liquid heating tank 3, prepare the leaching liquid, and pump the leaching liquid into the leaching tank from the bottom of the leaching tank 2 with the pump A4 In 2, a certain amount of leaching agent is replenished every day, and the ore leaching process is completed after a leaching cycle of 20 days, and then the leaching solution is discharged from the drain port at the bottom of the leachin...

Embodiment 2

[0071] The leaching process in the present invention is: select the ore with a copper grade of 1.800% and a copper metal content of 162 kg, and add 9 tons (dry weight) of the ore into the leaching tank 2, and the measured specific gravity is 1.56t / m 3 According to the mineral composition, calculate the amount of leaching agent and oxidant that should be added, add the leaching agent and oxidizing agent in two stages, first add the leaching agent in the leachate heating tank 3, and configure a 3 Use a pump with a pump head of 40m to drive the leachate into the leaching tank 2 from the bottom of the leaching tank 2, so that the leachate can seep out evenly on the surface of the ore, and then according to the analysis of the concentration of copper in the leachate and the concentration of the leaching agent, daily Supplement a certain amount of leaching agent, after a leaching cycle of 20 days, complete the ore leaching process, draw the daily leached copper amount and leaching ra...

Embodiment 3

[0081] Extraction process in the present invention: the leachate in the high-level storage tank 8 flows into the extraction and stripping tank 9 by itself, and the high-level storage tank 8 is connected with the extraction tank through a reinforced plastic pipe, and a gate valve is connected therebetween to control the flow of the leachate. After mixing, it enters the clarification chamber, the organic phase is in the upper layer, the leachate is in the lower layer, and the raffinate is returned to the leaching system for recycling;

[0082] The extraction conditions are:

[0083] 1) The average copper concentration of the feed liquid is 4.0g / L, the extraction rate is 80%, and the processing capacity of the feed liquid is 313L / d, 12L / h;

[0084] 2) The extraction adopts one-stage extraction and one-stage back-extraction, the extraction ratio is 1:1, and the back-extraction ratio is 1.5-2:1;

[0085] 3) 2 sets of stirring motors, 1 set for extraction and 1 set for stripping, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com