Water-soluble vitamin D3 nanometer particles and preparation method thereof

A technology of water-soluble vitamins and nanoparticles, which is used in food preparation, food forming, and food ingredients as solubility improvers. and other problems, to achieve the effects of good colloidal stability and chemical stability, good colloidal stability and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

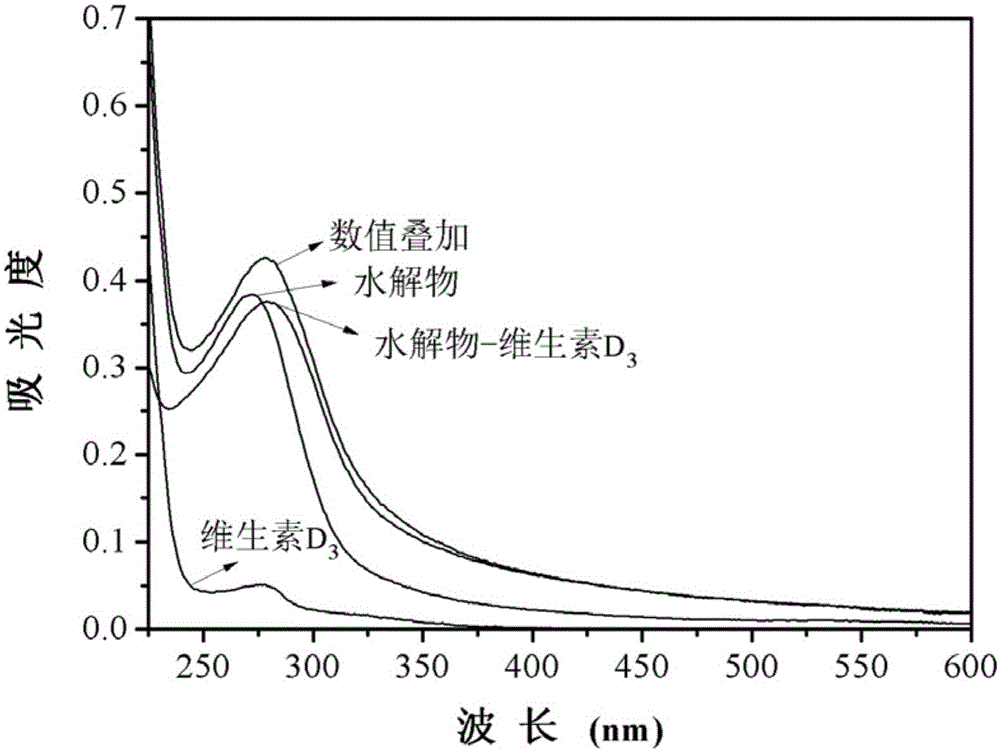

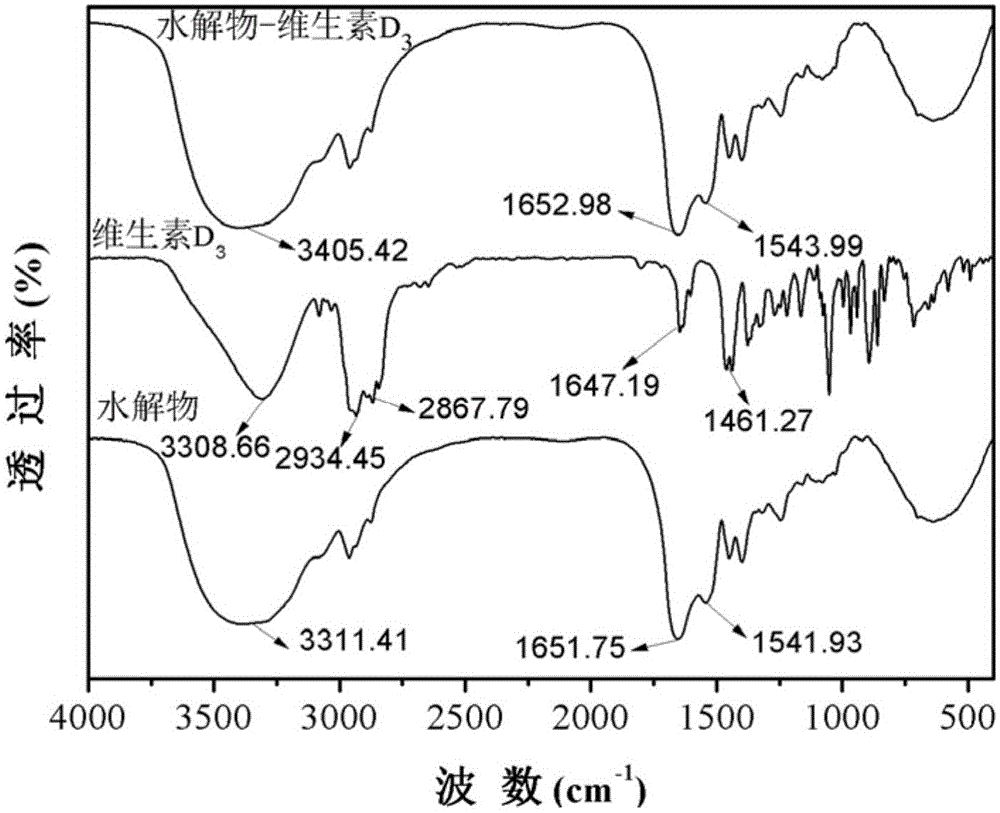

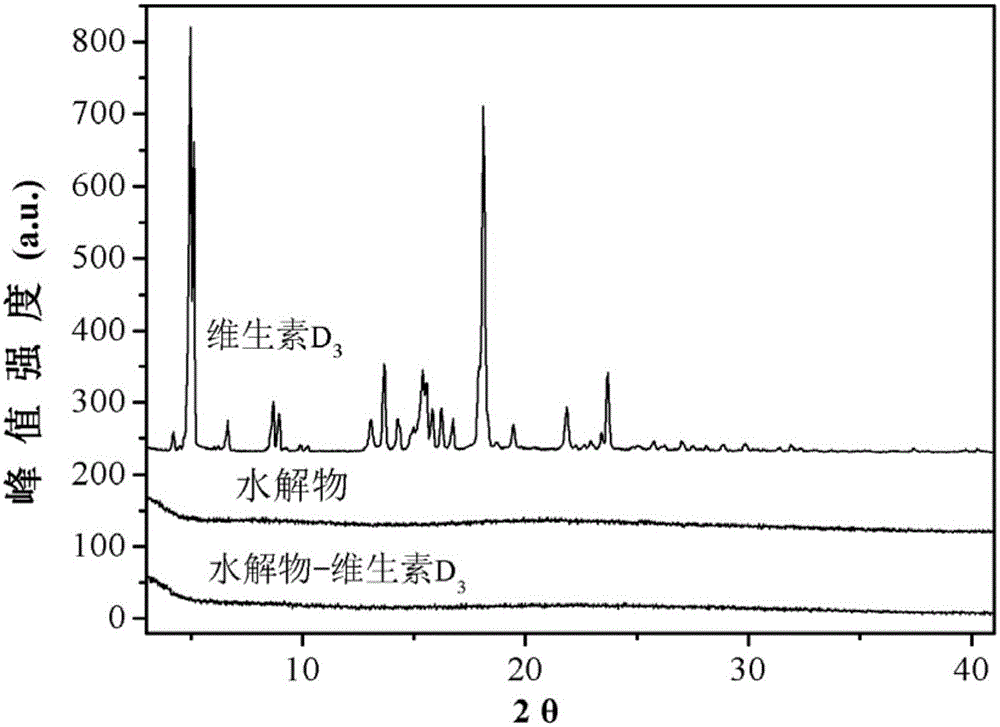

[0042] A water-soluble vitamin D 3 A method for preparing nanoparticles, comprising the steps of:

[0043] Step 1: Uniformly disperse corn protein concentrate (protein content: 87.5±0.6%, dry basis) in deionized water to prepare a 3% (w / v, g / mL) dispersion. Heat the dispersion in a water bath to 50° C. and adjust the pH to 9.0 with 1M NaOH, add Alcalase protease at a mass ratio of 2% for enzymolysis, and keep the temperature and pH constant for 2 hours. After the enzymatic hydrolysis, the pH of the material was adjusted to 7.0 with 1M HCl, and then heated in a boiling water bath for 5 minutes to inactivate the enzyme. After the hydrolyzate was centrifuged at 10000r / min for 20min, the supernatant was passed through a 0.65μm microfiltration membrane and put into a dialysis bag with a molecular weight cutoff of 100Da, and dialyzed in deionized water at 4°C for 24h, every 8 hours Change the dialysate once. After the dialysis, the zein hydrolyzate was obtained through rotary eva...

Embodiment 2

[0056] A preparation of vitamin D based on corn protein hydrolyzate 3 The method for nanoparticles, comprising the steps of:

[0057] Step 1: Uniformly disperse corn protein concentrate (protein content: 87.5±0.6%, dry basis) in deionized water to prepare a 3% (w / v, g / mL) dispersion. The dispersion solution was heated in a water bath to 50° C. and then adjusted to pH 9.0 with 1M NaOH. Alcalase protease was added at a mass ratio of 3% for enzymatic hydrolysis. The enzymatic hydrolysis was carried out for 1 h while maintaining a constant temperature and pH. After the enzymatic hydrolysis, the pH of the material was adjusted to 7.0 with 1M HCl, and then heated in a boiling water bath for 5 minutes to inactivate the enzyme. After the hydrolyzate was centrifuged at 10000r / min for 20min, the supernatant was passed through a 0.65μm microfiltration membrane and put into a dialysis bag with a molecular weight cutoff of 200Da, and dialyzed in deionized water at 4°C for 24h, every 8 hou...

Embodiment 3

[0064] A preparation of vitamin D based on corn protein hydrolyzate 3 The method for nanoparticles, comprising the steps of:

[0065] Step 1: Uniformly disperse corn gluten powder (protein content: 53.2±0.8%, dry basis) in deionized water to prepare a 5% (w / v, g / mL) dispersion. The dispersion solution was heated to 50°C in a water bath and then adjusted to pH 8.0 with 1M NaOH. Alcalase protease was added at a mass ratio of 1% for enzymatic hydrolysis. Under the condition of maintaining constant temperature and pH, the enzymatic hydrolysis was carried out for 3 hours. After the enzymatic hydrolysis, the pH of the material was adjusted to 6.0 with 1M HCl, and then heated in a boiling water bath for 5 minutes to inactivate the enzyme. After the hydrolyzate was centrifuged at 10000r / min for 20min, the supernatant was passed through a 0.65μm microfiltration membrane and put into a dialysis bag with a molecular weight cutoff of 100Da, and dialyzed in deionized water at 4°C for 24h,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com