Composite oxygenator for removing nitrite from aquaculture water and preparation method thereof

A technology for nitrite and aquaculture water, applied in the direction of microorganism-based methods, biochemical equipment and methods, chemical instruments and methods, etc., can solve the requirements of high-density aquaculture, insufficient degradation efficiency, and single function and other problems, to achieve the effect of helping food digestion and absorption, improving intestinal digestive function, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

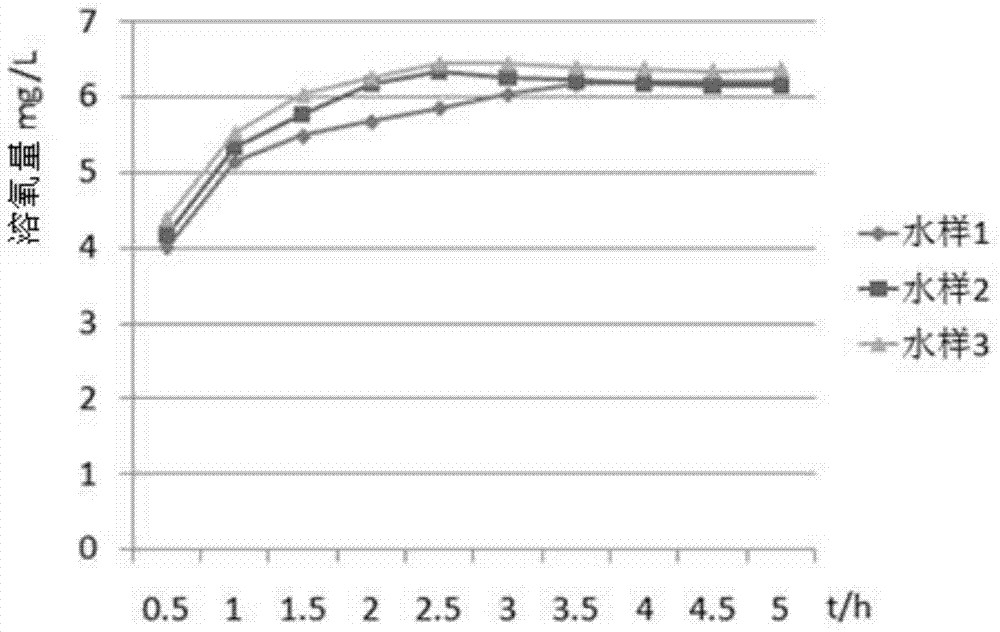

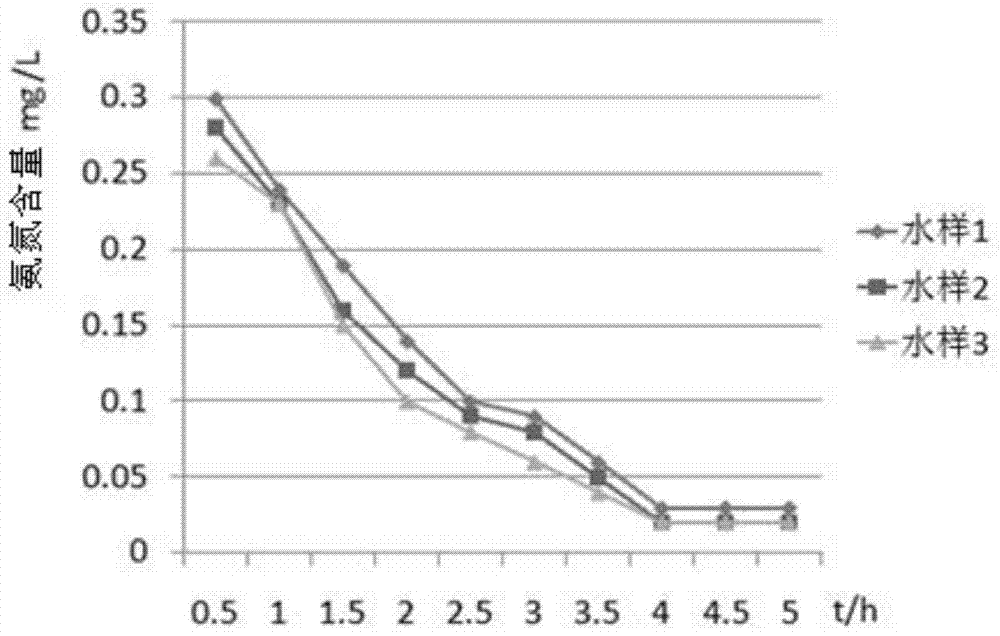

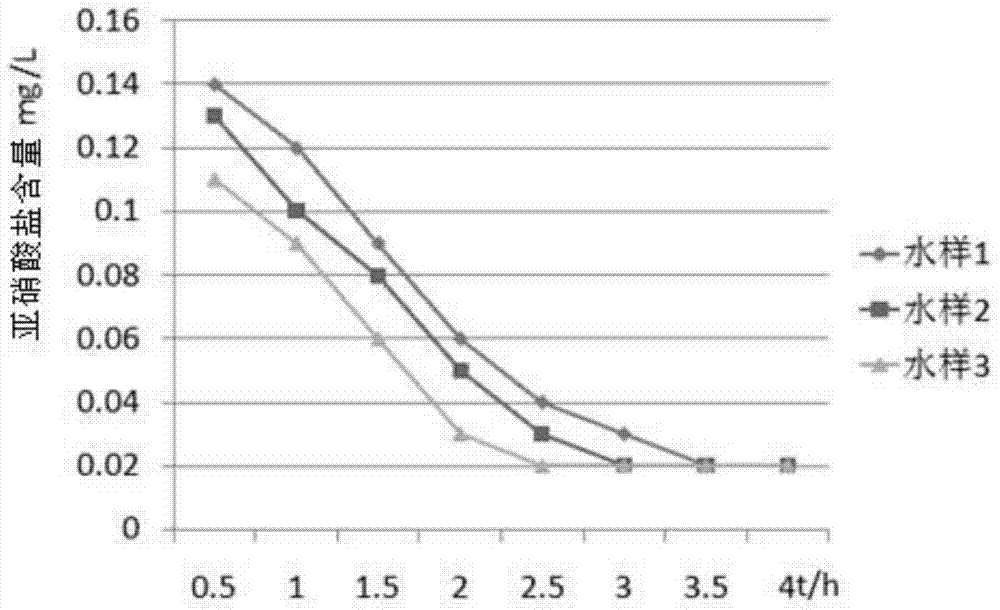

Embodiment 1

[0057] The composite oxygenator for removing nitrite in aquaculture water of this embodiment is prepared from the following components by weight:

[0058] 40 parts of oxygenation components, 24 parts of composite microbial agents, 5 parts of adsorbents, 1.0 parts of growth promoters (consisting of sodium pyruvate, p-aminophenyl arsenic acid, potassium chloride and a weight ratio of 1:1:2:2) Calcium sulfate), 7 parts of Chinese medicine admixture, 0.02 parts of sodium perchlorate, 1 part of sodium silicate, 1.4 parts of sodium alginate;

[0059] The specific preparation method is as follows:

[0060] (1) Oxygen-enhancing component treatment: Weigh percarbonamide and coated sodium percarbonate in a weight ratio of 1:3, put them in the mixer, and add 8% relative to the total weight of percarbonamide and coated sodium percarbonate The polyoxyethylene monostearate is mixed with a mixer for 5 minutes, and the mixture is evenly mixed into a dry mixed powder to obtain the oxygen-enhancing c...

Embodiment 2

[0074] The composite oxygenator for removing nitrite in aquaculture water of this embodiment is prepared from the following components by weight:

[0075] 45 parts of oxygen-enhancing ingredients, 31 parts of composite microbial agents, 17 parts of adsorbents, and 1.75 parts of growth promoters (consisting of sodium pyruvate, p-aminophenylarsenic acid, potassium chloride and a weight ratio of 1:1:2:2) Calcium sulfate), 8.5 parts of Chinese medicine admixture, 0.05 parts of sodium perchlorate, 2 parts of magnesium silicate, 1.8 parts of sodium alginate;

[0076] The specific preparation method is as follows:

[0077] (1) Oxygen-enhancing component treatment: Weigh percarbonamide and coated sodium percarbonate in a weight ratio of 1:4, put them in the mixer, and add 16.5% of the total weight of percarbonamide and coated sodium percarbonate Adipic acid, mixed with a mixer for 12.5 minutes, mixed evenly into a dry mixed powder, to obtain oxygen-enhancing ingredients;

[0078] (2) Prepara...

Embodiment 3

[0091] The composite oxygenator for removing nitrite in aquaculture water of this embodiment is prepared from the following components by weight:

[0092] 50 parts of oxygenation components, 38 parts of composite microbial agents, 29 parts of adsorbents, 2.5 parts of growth promoters (consisting of sodium pyruvate, p-aminophenyl arsenic acid, potassium chloride and the weight ratio of 1:1:2:2 Calcium sulfate), 10 parts of Chinese medicine admixture, 0.12 parts of sodium perchlorate, 3 parts of nitrilo trimethylene phosphoric acid, 2.2 parts of polyvinyl alcohol;

[0093] The specific preparation method is as follows:

[0094] (1) Oxygen-enhancing component treatment: Weigh percarbonamide and coated sodium percarbonate in a weight ratio of 1:5, put them in the mixer, and add 25% of the total weight of percarbonamide and coated sodium percarbonate The adipic acid is mixed with a mixer for 20 minutes, and the mixture is evenly mixed into a dry mixed powder to obtain the oxygen-enhancin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com