Method for preparing cathode material of lithium ion battery from mixed waste alkaline batteries

A lithium-ion battery and positive electrode material technology, which is applied in the field of solid waste recycling, can solve the problems of limiting the recycling efficiency of mixed waste batteries of various types, achieve superior performance and save raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

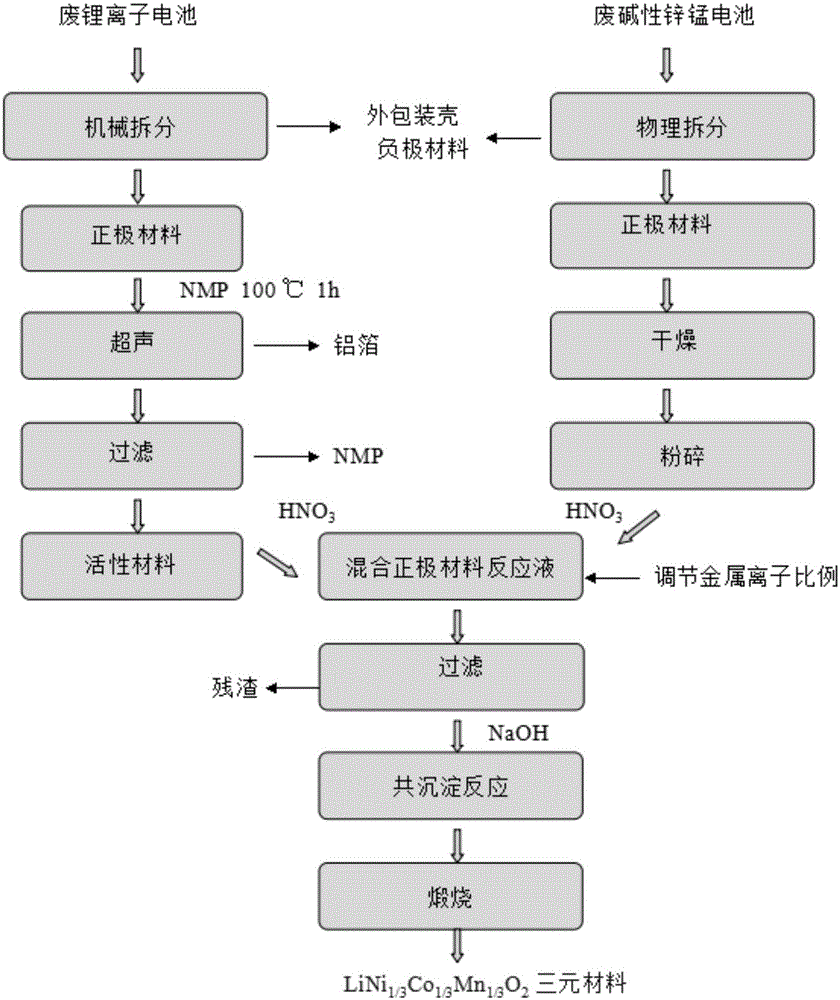

Method used

Image

Examples

Embodiment 1

[0017] Optimization of dissolution conditions for mixed spent alkaline batteries.

[0018] For waste lithium-ion batteries, first connect the positive and negative electrodes with wires to make them self-discharge, so as to prevent discharge or spontaneous combustion during manual disassembly. The positive electrode material containing aluminum foil is then separated. When optimizing the separation conditions of the cathode material and aluminum foil, water, carbon tetrachloride, dichloromethane, and NMP were selected as ultrasonic solvents. The results showed that no matter what type and brand of lithium cobaltate cathode material, NMP was used as the ultrasonic solvent. Ultrasound for 3 minutes can completely separate the positive electrode material and aluminum foil. Filter and dry. The positive electrode active material of the lithium ion battery can be obtained. For the spent alkaline zinc-manganese battery, use a hacksaw to saw from the battery collector, and manually...

Embodiment 2

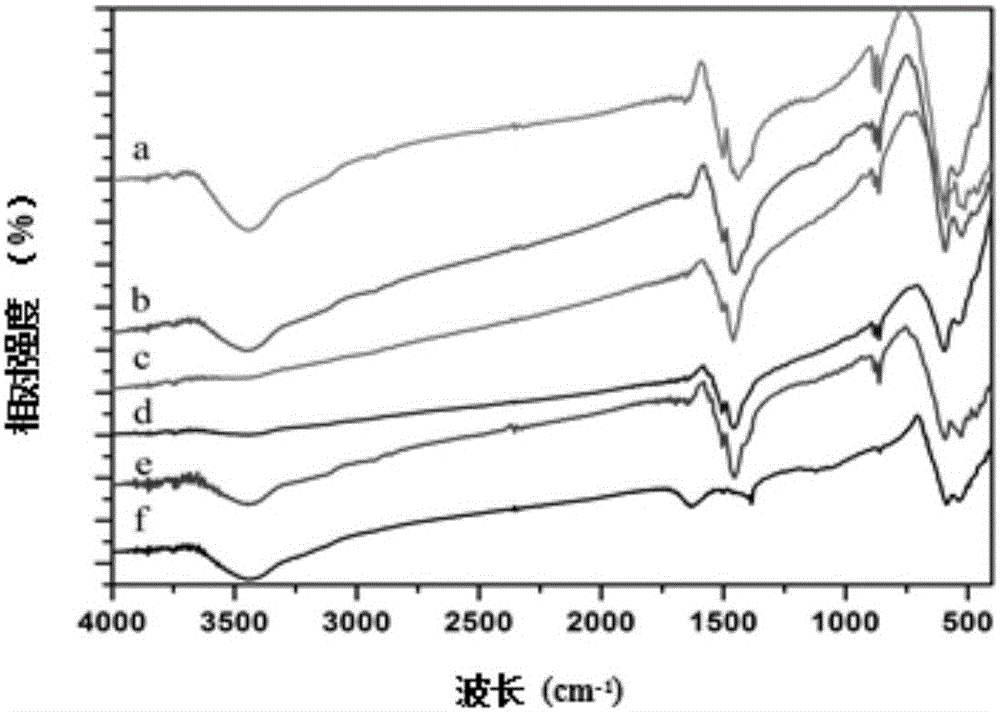

[0020] Preparation of LiNi under different pH conditions 1 / 3 co 1 / 3 mn 1 / 3 o 2 IR of cathode material picture Spectrum.

[0021] When different gelling agents or precipitating agents are used to form gels, their polarity, polar moment and access to active ions are different. There will be different effects on the exchange reaction in the sol. When only water is used as a solvent, the precursor does not contain active substances that can undergo polycondensation reactions, and the cross-linking between the products is only through heating, stirring and evaporating the solvent, so that the products can be connected by hydrogen bonds to form a gel. When absolute ethanol or ethylene glycol is used as a solvent, adding citric acid as a gelling agent can form a gel. The reason for the formation of the gel is that the citric acid and the solvent undergo a strong polymerization reaction and quickly form a continuous three-dimensional network. structure. In this experiment, wat...

Embodiment 3

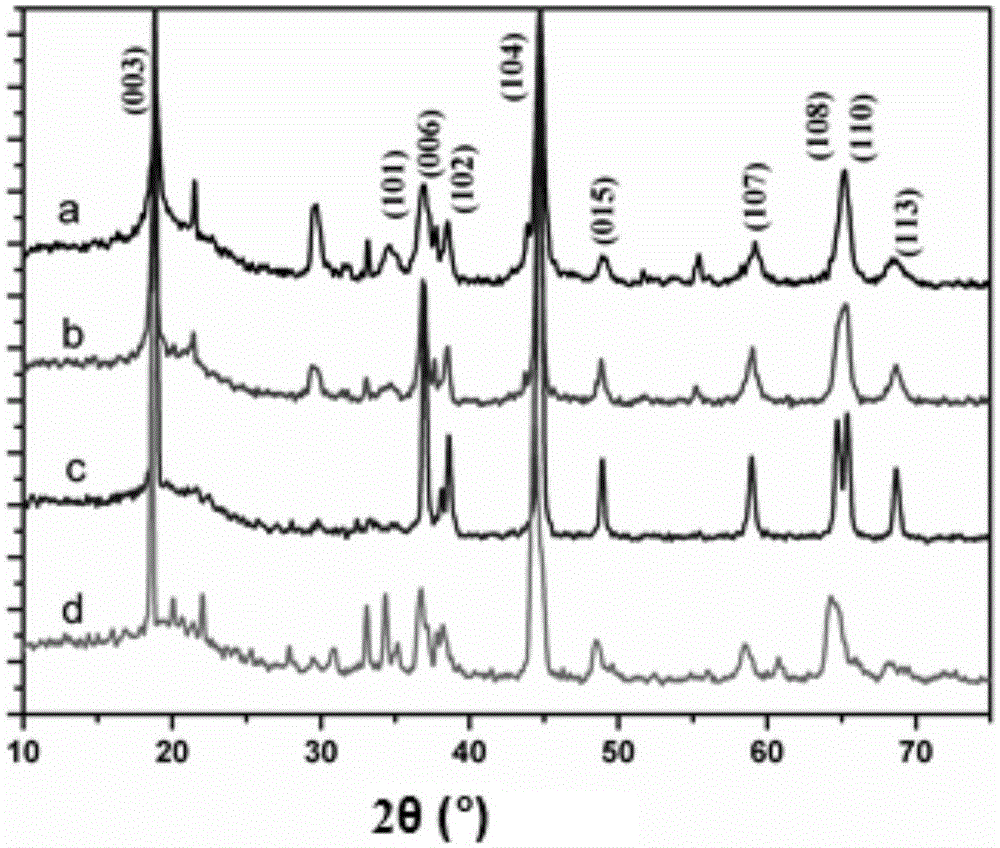

[0023] Effect of different calcination temperatures on LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The influence of cathode material preparation.

[0024] Depend on image 3 It can be seen that the XRD in the case of a, b, and d calcined picture There are miscellaneous peaks in the spectra, but c has better crystallinity in the case of calcination; this result shows that the calcination temperature gradually increases, and the crystal grains are gradually formed, but when the calcination temperature is too high, micropore shrinkage may occur and agglomeration occurs. If the calcination temperature is too low, the precursor may not be completely decomposed. On the whole, the crystallinity is strong at 850°C, and there is no impurity peak.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com