Production method for electrolytic manganese metal

A technology of electrolytic manganese metal and production method, which is applied in the direction of photography technology, instruments, photography auxiliary technology, etc., can solve the problems of increased cost, small profit margin, health damage of operators, etc., and achieves good economic and social benefits, high raw material Utilization rate and the effect of preventing material and liquid from splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

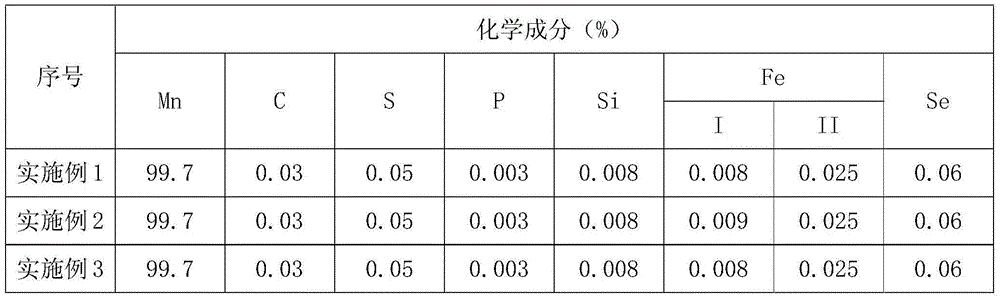

Embodiment 1

[0024] A method for producing electrolytic manganese metal, comprising the steps of preparing ore pulp, neutralizing and removing iron, purifying and removing impurities, electrolyzing, passivating, stripping, and cleaning. The specific process is as follows:

[0025] Preparation of ore pulp: firstly, the low-grade rhodochrosite with a manganese weight fraction of 13% is coarsely crushed and finely crushed to 200 mesh to obtain rhodochrosite powder; the anolyte is dropped into the leaching tank, and the anolyte is the waste liquid produced by electrolytic manganese. After testing, the concentration of sulfuric acid is 30g / L, NH 4+ The concentration is 85g / L, Mn 2+ The concentration is 10g / L. Add rhodochrosite powder according to the ratio of rhodochrosite powder: anolyte weight ratio of 1:2, stir for 5 minutes to disperse the ore powder evenly, and then add the concentration of 90g / l of concentrated sulfuric acid, the reaction temperature is controlled at 75-80°C, in order ...

Embodiment 2

[0033] A method for producing electrolytic manganese metal, comprising the steps of preparing ore pulp, neutralizing and removing iron, purifying and removing impurities, electrolyzing, passivating, stripping, and cleaning. The specific process is as follows:

[0034] Preparation of ore pulp: firstly, the low-grade rhodochrosite with a manganese weight fraction of 16% is coarsely crushed and finely crushed to 160 mesh to obtain rhodochrosite powder; the anolyte is dropped into the leaching tank, and the anolyte is the waste liquid produced by electrolytic manganese. After testing, the concentration of sulfuric acid is 35g / L, NH 4+ The concentration is 100g / L, Mn 2+ The concentration is 15g / L. Add rhodochrosite powder according to the ratio of rhodochrosite powder: anolyte weight ratio of 1:4, stir for 10 minutes to disperse the ore powder evenly, and then add the concentration of 100g / 1 of concentrated sulfuric acid, control the reaction temperature at 85-90°C, in order to ...

Embodiment 3

[0042] A method for producing electrolytic manganese metal, comprising the steps of preparing ore pulp, neutralizing and removing iron, purifying and removing impurities, electrolyzing, passivating, stripping, and cleaning. The specific process is as follows:

[0043] Preparation of ore pulp: firstly, the low-grade rhodochrosite with a manganese weight fraction of 15% is coarsely crushed and finely crushed to 200 mesh to obtain rhodochrosite powder; the anolyte is dropped into the leaching tank, and the anolyte is the waste liquid produced by electrolytic manganese. After testing, the concentration of sulfuric acid is 32g / L, NH 4+ The concentration is 90g / L, Mn 2+ The concentration is 12g / L. Add rhodochrosite powder according to the ratio of rhodochrosite powder: anolyte weight ratio of 1:3, stir for 8 minutes to disperse the ore powder evenly, and then add the concentration of 95g / l of concentrated sulfuric acid, control the reaction temperature at 85-90 ° C, in order to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com