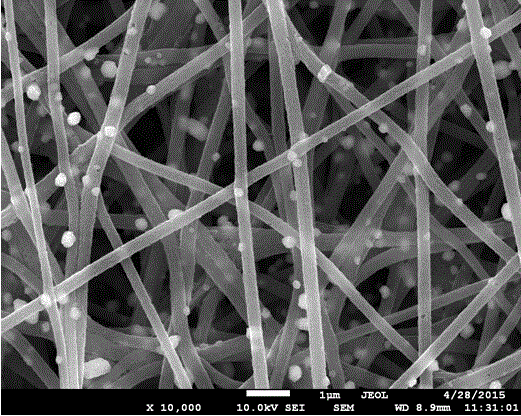

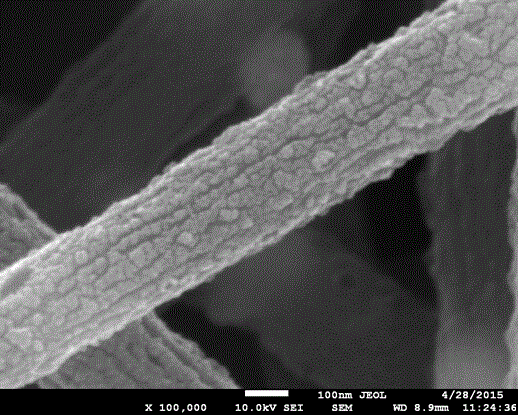

Graphene-doped porous carbon/ferroferric oxide nano-fiber lithium battery anode material and preparation method thereof

A technology of ferroferric oxide and nanofibers, which is applied in battery electrodes, fiber treatment, secondary batteries, etc., can solve the problems of poor charge transmission and diffusion performance, volume change particle agglomeration, and poor cycle stability, so as to improve cycle stability The effect of high performance and rate performance, simple processing, and large porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of the porous carbon / ferric oxide nanofiber lithium battery negative electrode material doped with graphene adopts the following steps:

[0021] (1) Put graphene oxide into N-N dimethylformamide, ultrasonically disperse it for 8 hours, add polyacrylonitrile powder, polymethyl methacrylate powder and iron salt, and stir at 80°C for 4 hours to obtain electrospun silk solution. The mass fraction of polyacrylonitrile is 6-10%, the mass fraction of polymethyl methacrylate is 5-10%, and the mass fraction of iron salt is 20-30%;

[0022] (2) Transfer the electrospinning solution obtained in step (1) to a syringe for electrospinning. The spinning voltage is 10-30kv, the spinning flow rate is 0.1-2.0ml / h, and the distance between the needle tip and the receiving plate is 10-30cm;

[0023] (3) Pre-oxidize the nanofibers obtained in step (2) at 200-300°C in an air atmosphere, and then transfer them to a carbonization furnace. The rate is raised to 600°C, ...

Embodiment 2

[0028] The preparation method of the porous carbon / ferric oxide nanofiber lithium battery negative electrode material doped with graphene adopts the following steps:

[0029] (1) Put graphene oxide into N-N dimethylformamide, ultrasonically disperse for 8 hours, add polyacrylonitrile powder, polymethyl methacrylate powder and iron salt, and stir at 80°C for 5 hours to obtain electrospun Silk solution, the mass fraction of polyacrylonitrile is 6-10%, the mass fraction of polymethyl methacrylate is 5-10%, and the mass fraction of iron salt is 20-30%;

[0030] (2) Transfer the electrospinning solution obtained in step (1) to a syringe for electrospinning, the spinning voltage is 10-30kv, the spinning flow rate is 0.1-2.0ml / h, the distance between the needle tip and the receiving plate The distance is 10-30cm;

[0031] (3) Pre-oxidize the nanofibers obtained in step (2) at 200-300°C in an air atmosphere, and then transfer them to a carbonization furnace. The rate is raised to 65...

Embodiment 3

[0034] The preparation method of the porous carbon / ferric oxide nanofiber lithium battery negative electrode material doped with graphene adopts the following steps:

[0035] (1) Put graphene oxide into N-N dimethylformamide, ultrasonically disperse for 8 hours, add polyacrylonitrile powder, polymethyl methacrylate powder and iron salt, and stir at 80°C for 5 hours to obtain electrospun silk solution. The mass fraction of polyacrylonitrile is 6-10%, the mass fraction of polymethyl methacrylate is 5-10%, and the mass fraction of iron salt is 20-30%;

[0036] (2) Transfer the electrospinning solution obtained in step (1) to a syringe for electrospinning. The spinning voltage is 10-30kv, the spinning flow rate is 0.1-2.0ml / h, and the distance between the needle tip and the receiving plate is 10-30cm;

[0037] (3) Pre-oxidize the nanofibers obtained in step (2) at 200-300°C in an air atmosphere, and then transfer them to a carbonization furnace. The rate is raised to 700°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com