Oil-resistant anti-corrosion waterborne paint and preparation method thereof

A water-based paint, oil-resistant technology, used in anti-corrosion coatings, polyester coatings, coatings, etc., can solve problems such as single function, weak adhesion, poor oil resistance and anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

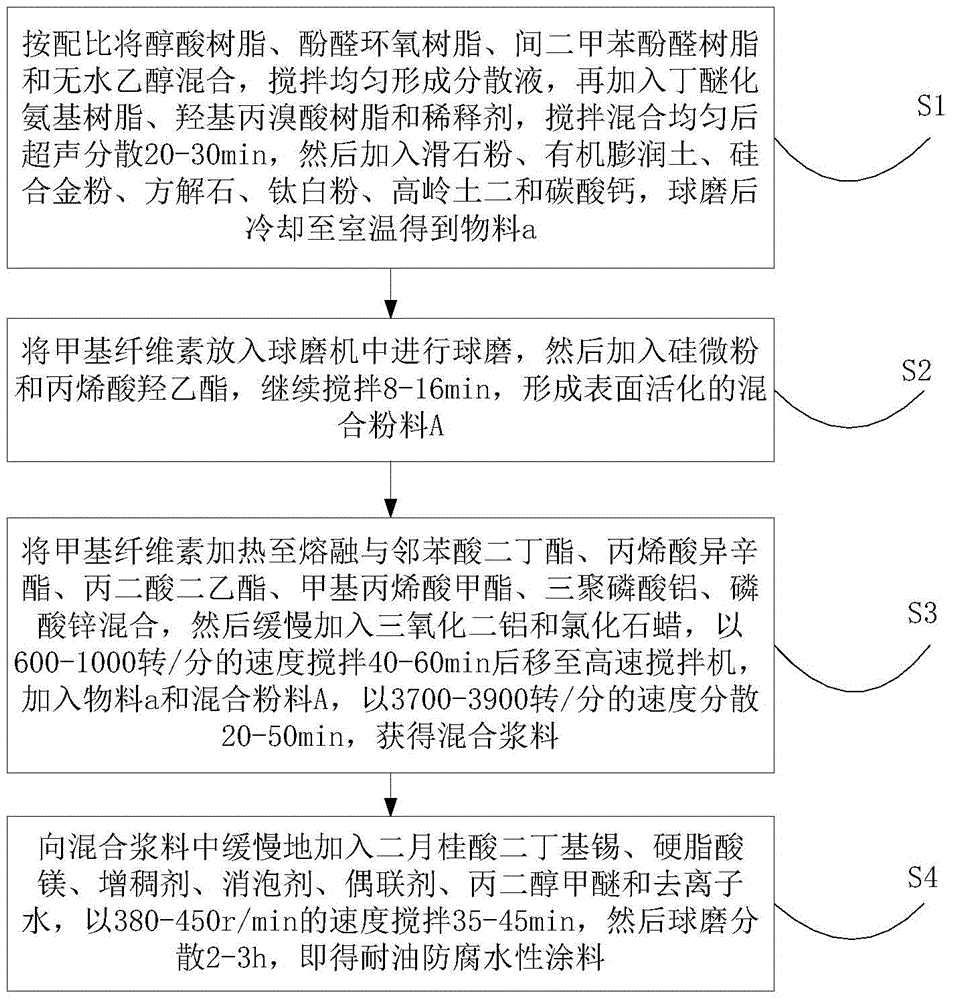

[0021] refer to figure 1 , the preparation method of a kind of oil-resistant anticorrosion water-based paint that the present invention proposes, comprises the steps:

[0022] S1. Mix alkyd resin, novolac epoxy resin, m-xylenol phenolic resin and absolute ethanol according to the proportion, stir evenly to form a dispersion, then add butylated amino resin, hydroxypropanol resin and diluent, stir and mix After uniformity, ultrasonically disperse for 20-30 minutes, then add talcum powder, organic bentonite, silicon alloy powder, calcite, titanium dioxide, kaolin and calcium carbonate, and cool to room temperature after ball milling to obtain material a;

[0023] S2. Put the methyl cellulose into a ball mill for ball milling, then add silicon micropowder and hydroxyethyl acrylate, and continue stirring for 8-16 minutes to form a surface-activated mixed powder A;

[0024] S3. Heat methyl cellulose to melt and mix with dibutyl phthalate, isooctyl acrylate, diethyl malonate, methyl...

Embodiment 1

[0028] A kind of oil-resistant anticorrosion water-based coating that the present invention proposes, its raw material comprises by weight: 100 parts of alkyd resin, 35 parts of phenolic epoxy resin, 10 parts of m-xylenol phenolic resin, 5.5 parts of butylated amino resin, hydroxypropyl bromide 10 parts of acid resin, 5.5 parts of dibutyl phthalate, 5.5 parts of hydroxyethyl acrylate, 4.5 parts of isooctyl acrylate, 4.5 parts of diethyl malonate, 5 parts of methyl methacrylate, 4 parts of aluminum tripolyphosphate 3 parts of zinc phosphate, 4.5 parts of absolute ethanol, 6 parts of aluminum oxide, 6.5 parts of chlorinated paraffin, 5 parts of methyl cellulose, 4 parts of talcum powder, 5.5 parts of organic bentonite, 5.5 parts of silicon alloy powder, calcite 3.5 parts, 6 parts of zinc stearate, 5.5 parts of titanium dioxide, 4 parts of kaolin, 6.5 parts of calcium carbonate, 3 parts of silicon micropowder, 4.5 parts of dibutyltin dilaurate, 3.5 parts of magnesium stearate, 3.5...

Embodiment 2

[0035] A kind of oil resistant anticorrosion water-based coating that the present invention proposes, its raw material comprises by weight: 80 parts of alkyd resin, 50 parts of phenolic epoxy resin, 5 parts of m-xylenol phenolic resin, 9 parts of butylated amino resin, hydroxypropyl bromide 5 parts of acid resin, 8 parts of dibutyl phthalate, 2 parts of hydroxyethyl acrylate, 6 parts of isooctyl acrylate, 1 part of diethyl malonate, 8 parts of methyl methacrylate, 2 parts of aluminum tripolyphosphate 5 parts of zinc phosphate, 3 parts of absolute ethanol, 9 parts of aluminum oxide, 4 parts of chlorinated paraffin, 8 parts of methyl cellulose, 1 part of talcum powder, 8 parts of organic bentonite, 2 parts of silicon alloy powder, calcite 6 parts, 4 parts of zinc stearate, 9 parts of titanium dioxide, 2 parts of kaolin, 9 parts of calcium carbonate, 1 part of silicon micropowder, 7 parts of dibutyltin dilaurate, 1 part of magnesium stearate, 6 parts of thickener, 2 parts of dilu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com