Ti/W/Mo oxide in-situ reinforced platinum/palladium nanostructured composite catalyst and preparation method thereof

A composite catalyst and oxide technology, applied in the fields of electrocatalysis and material science, can solve the problems of high cost, complicated steps, environmental damage, etc., and achieve high production efficiency, simple and easy method, and improved chemical stability and structural stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

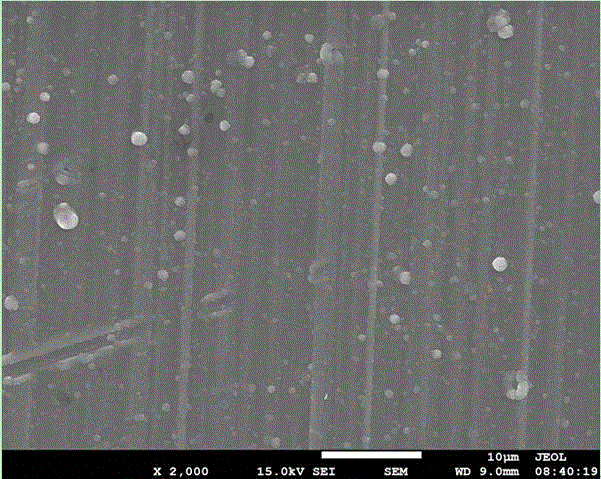

[0035] A kind of oxide in situ enhanced platinum (palladium) nanostructure composite electrocatalyst and preparation method thereof, wherein the oxide nanostructure generated in situ is titanium oxide, noble metal is platinum, wherein the ratio of titanium oxide to platinum is roughly 1: 3. Add 50% carbon powder and mix evenly, and load it on the surface of glassy carbon electrode for related electrochemical tests.

[0036] The preparation method of the above titanium oxide in situ reinforced platinum nanostructure composite electrocatalyst is as follows:

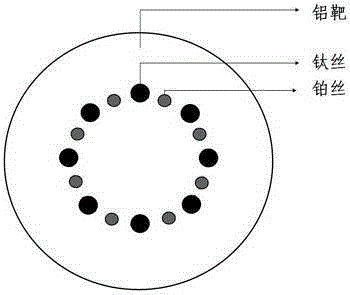

[0037] First process a suitable mosaic composite target, such as attached figure 1 As shown, the aluminum target is selected as the base target, with a diameter of 100mm and a thickness of 6mm. Holes are evenly spaced along the area where the magnetic field lines are dense during the magnetron sputtering process, and titanium wires and platinum wires are implanted to make them closely bonded to each other. The surface is s...

Embodiment 2

[0042] An oxide in-situ enhanced platinum (palladium) nanostructure composite electrocatalyst and preparation method thereof, wherein the oxide nanostructure generated in situ is tungsten oxide, and the noble metal is platinum, wherein the ratio of tungsten oxide to platinum is approximately 1: 1.

[0043] The preparation method of the above tungsten oxide in-situ reinforced platinum nanostructure composite electrocatalyst is as follows:

[0044] Firstly, a suitable mosaic composite target is processed, and an aluminum target is selected as the base target. Holes are uniformly drilled and implanted with tungsten wires and platinum wires at intervals along the magnetron sputtering process where the magnetic force lines are dense, so that they are closely bonded to each other, and the surface Flatten, place the prepared composite target on the target position of the magnetron sputtering furnace. Clean the copper strip substrate, and carry out ultrasonic treatment with deionized...

Embodiment 3

[0047] A kind of oxide in situ enhanced platinum (palladium) nanostructure composite electrocatalyst and preparation method thereof, wherein the oxide nanostructure generated in situ is molybdenum oxide, noble metal is palladium, wherein the ratio of molybdenum oxide to palladium is approximately 1: 1.

[0048] The preparation method of the molybdenum oxide in-situ reinforced palladium nanostructure composite electrocatalyst is as follows:

[0049] Firstly, a suitable mosaic composite target is processed, and the aluminum target is selected as the base target, and holes are evenly spaced along the area where the magnetic force lines are dense during the magnetron sputtering process, and molybdenum wire and palladium wire are implanted to make them closely bonded to each other. Flatten, place the prepared composite target on the target position of the magnetron sputtering furnace. Clean the inorganic silicate glass substrate and perform ultrasonic treatment with deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com