Continuous preparation method for producing chlorohydrocarbon through carbon tetrachloride and olefins

A technology of carbon tetrachloride and chlorinated hydrocarbons, which is applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, and chemical recovery, etc. It can solve the problems of iron powder or iron filler activity, production continuity, destructiveness, and difficulty in removal, etc. problems, to avoid mutual adhesion and agglomeration, improve reaction effect, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention is a kind of continuous preparation method that is used for carbon tetrachloride and olefin production chlorinated hydrocarbon, comprises the following steps:

[0029] (1) Iron powder or iron filler, catalyst auxiliary agent alkyl phosphate and carbon tetrachloride are continuously added in the first ferrous complex catalyst preparation kettle, and iron filler includes iron material, such as iron ring, Iron wire, iron filings, even stainless steel, carbon steel, etc., as long as they are iron-containing substances, make iron fillers easier to obtain and reduce costs. Catalyst additives are selected from triethyl phosphate, tributyl phosphate, trimethyl phosphate One or more mixtures of alkyl phosphates such as esters and triphenyl phosphate, through the use of catalyst aids, the reaction efficiency is accelerated, and the ratio of the amount of carbon tetrachloride to olefins is 1 to 10 : 1, the mass percentage that catalyst auxiliary agent account...

Embodiment 1

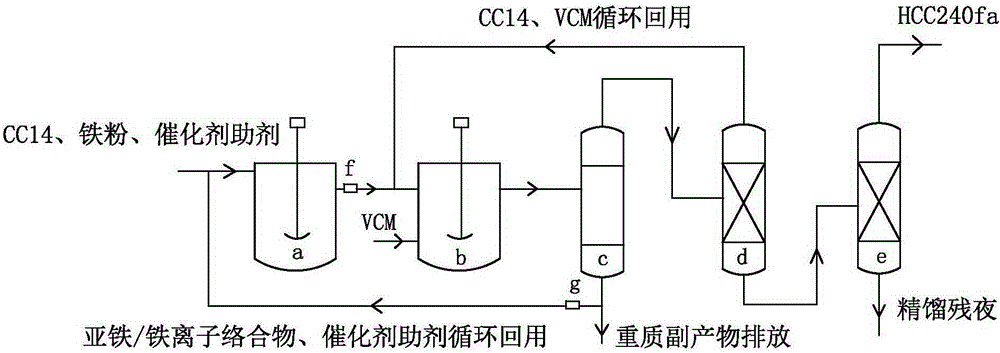

[0033] Such as figure 1 shown

[0034] Carbon tetrachloride, iron powder (80 mesh) and triethyl phosphate are mixed and transported to a 100 liter ferrous complex catalyst preparation kettle through a slurry pump. The reaction temperature in the kettle is 100 ° C, and the reaction pressure is 0.15 MPa. The time is 1h, and the material mixture after the reaction is transported in the second 100 liters of chlorinated hydrocarbon synthesis reactors quickly through the filter, the distance between the two stills is 1.5m, and the inner diameter of the delivery pipe is 75mm, vinyl chloride (VCM) from The lower part is passed into the chlorinated hydrocarbon synthesis reactor and carbon tetrachloride for telomerization reaction. The ratio of carbon tetrachloride, vinyl chloride and triethyl phosphate is 70:14:1, and iron powder accounts for 1% of the mixed material. The mass percentage is 0.1wt%, the reaction temperature is 100°C, the reaction pressure is 0.2MPa, and the reaction re...

Embodiment 2

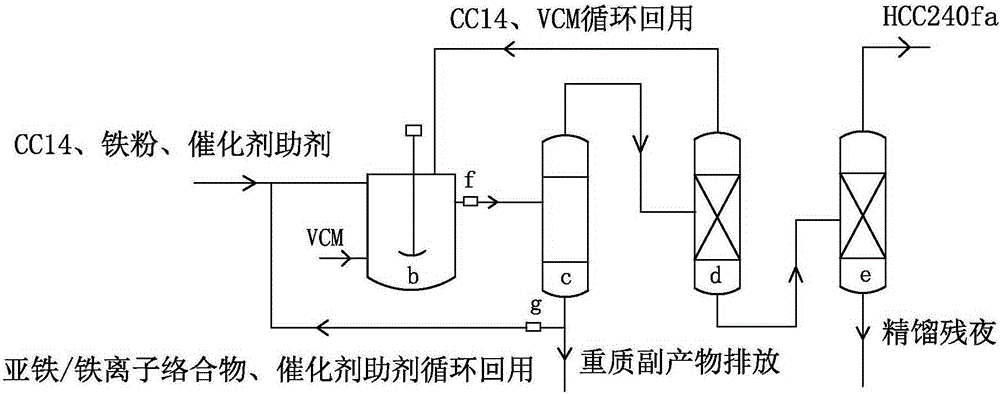

[0038] Such as figure 2 shown

[0039] Carbon tetrachloride, iron powder (80 mesh) and triethyl phosphate are mixed and transported to a 100-liter chlorinated hydrocarbon synthesis reaction kettle through a paddle pump, and vinyl chloride is passed into the chlorinated hydrocarbon synthesis reaction kettle and carbon tetrachloride from the lower part. Telomerization reaction, the ratio of carbon tetrachloride, vinyl chloride, and triethyl phosphate is 70:14:1, the mass percentage of iron powder in the mixed material is 0.1wt%, the reaction temperature is 100°C, and the reaction pressure is 0.2MPa, and the reaction residence time is 1h.

[0040] The reaction product is sent to the thin-film evaporator for flash evaporation after passing through the filter to remove iron powder. Light components such as carbon tetrachloride, vinyl chloride and chlorinated hydrocarbons (HCC240fa) enter the primary distillation tower, and the unreacted product is extracted from the top of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com