Oxidized graphene metal/metallic oxide nanoparticle modified hollow fiber ultrafiltration membrane, and preparation method thereof

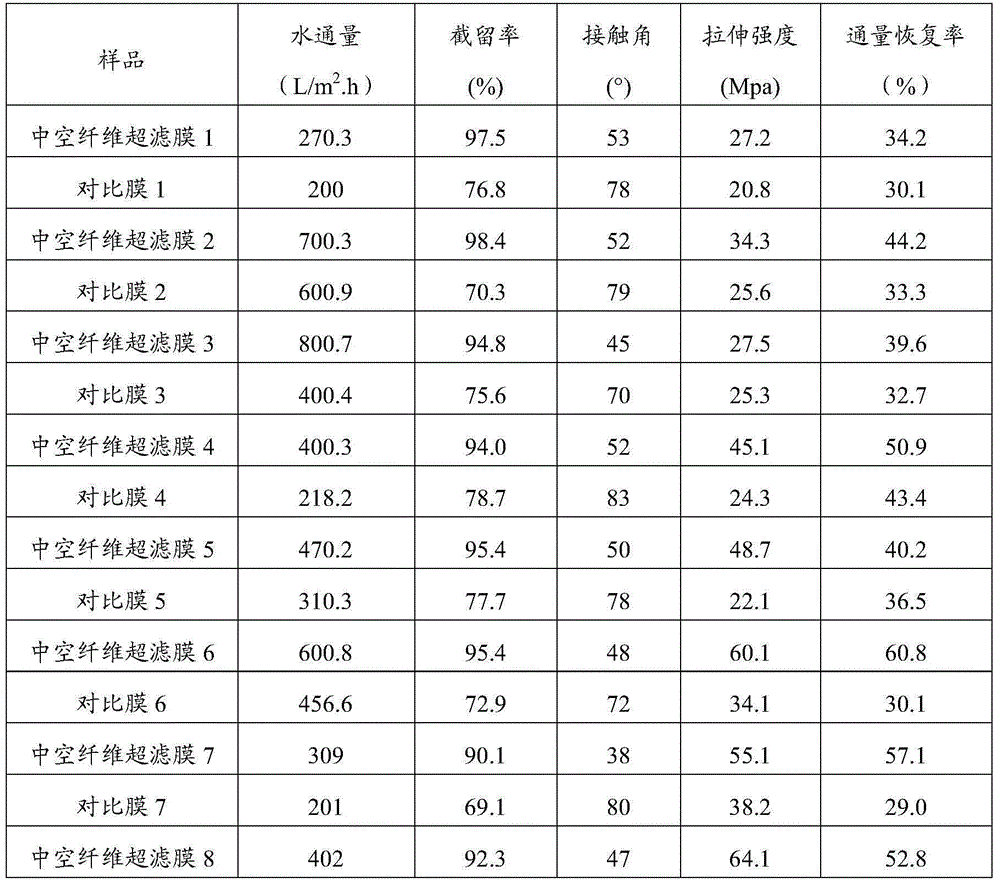

A technology of nano-particles and oxides, applied in chemical instruments and methods, ultrafiltration, membrane technology, etc., can solve the problems of shortening the service life of the membrane, polluting the filtered water body, and easy to fall off the membrane body, etc., to achieve large water flux, pro- Strong water and good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

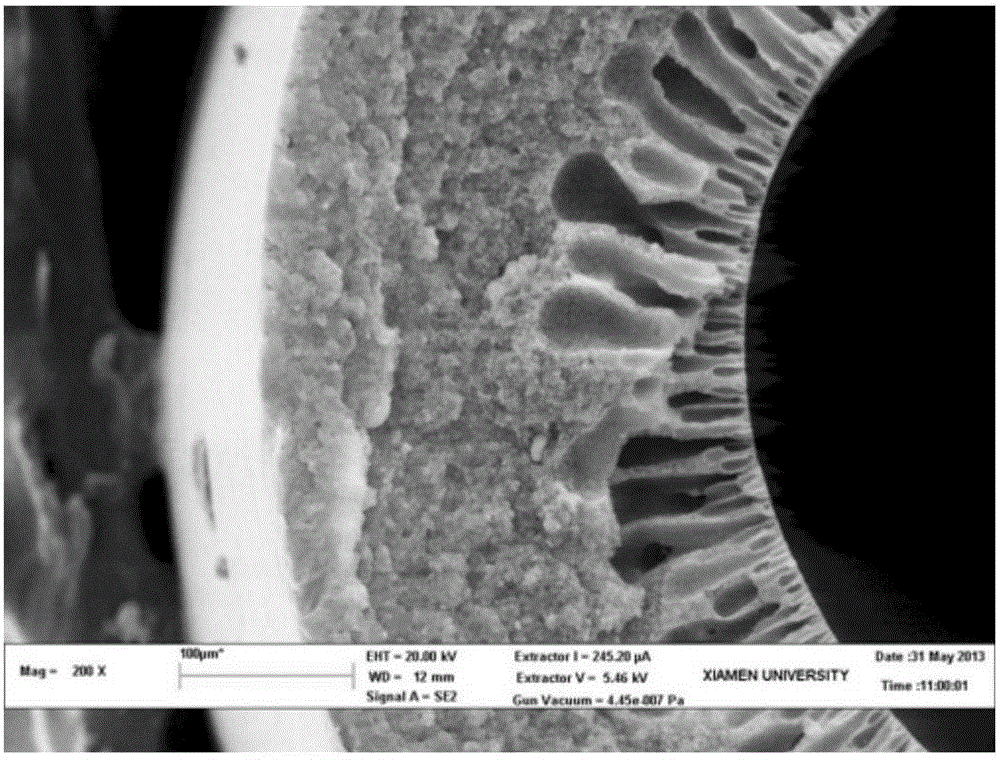

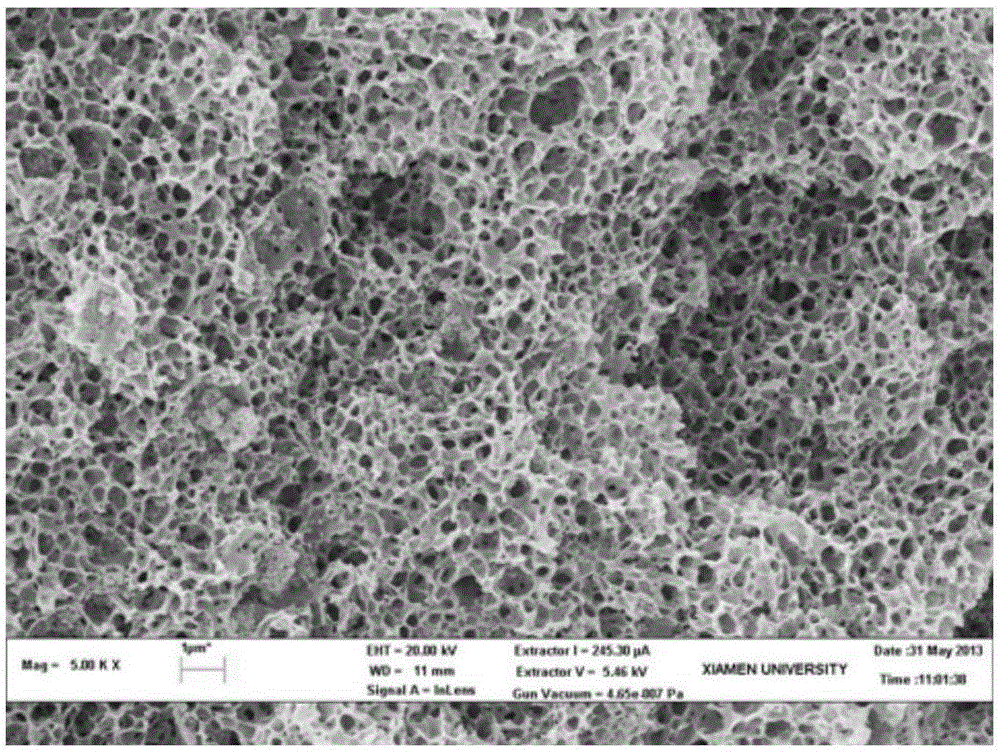

Image

Examples

Embodiment 1

[0030] 1) Mix 1 part of graphene oxide, 0.001 part of silver nanoparticles, and 200 parts of water-methanol mixture with a first solvent volume ratio of 1:1, and ultrasonically disperse to obtain a graphene oxide silver nanoparticle dispersion;

[0031] 2) 10 parts of high molecular polymer membrane material polyvinylidene fluoride, 30 parts of porogen lithium nitrate, 59.9 parts of second solvent dimethylformamide, and 0.1 part of graphene oxide silver nanoparticle dispersion were uniformly mixed to obtain cast Membrane fluid;

[0032] 3) Leave the casting solution to defoam for 24 hours and then extrude the core solution from the spinning nozzle at the same time. The temperature of the spinning nozzle is 50°C. The casting solution passes through the air at a speed of 0.5m / min and then enters the coagulation bath, stay in the coagulation bath for 3s, take it out, and obtain a hollow fiber ultrafiltration membrane 1 modified by graphene oxide silver nanoparticles; place it in ...

Embodiment 2

[0040] 1) 1 part of graphene oxide, 3 parts of copper nanoparticles, and 10 parts of the first solvent ethanol are mixed and ultrasonically dispersed to obtain a dispersion of graphene oxide copper nanoparticles;

[0041] 2) 10 parts of polymer film material polyvinyl chloride, 5 parts of porogen sodium chloride, 70 parts of second solvent dimethylacetamide, and 15 parts of graphene oxide copper nanoparticle dispersion are uniformly mixed to obtain a casting Membrane fluid;

[0042] 3) Leave the casting solution to defoam for 24 hours and extrude the core solution from the spinning nozzle at the same time. The temperature of the spinning nozzle is 90°C. The casting solution passes through a distance of 5mm at a speed of 3m / min in the air and then solidifies. bath, stay in the coagulation bath for 20s, take it out, and obtain the hollow fiber ultrafiltration membrane 2 modified by graphene oxide copper nanoparticles; place it in an aqueous solution for rinsing for 24 hours, and...

Embodiment 3

[0047] 1) 1 part of graphene oxide, 3 parts of gold nanoparticles, and 200 parts of the first solvent acetone are mixed and ultrasonically dispersed to obtain a graphene oxide gold nanoparticle dispersion;

[0048] 2) 30 parts of polymer membrane material polysulfone, 3 parts of porogen calcium chloride and 2 parts of calcium nitrate, 55 parts of second solvent dimethyl sulfoxide, and 10 parts of graphene oxide gold nanoparticle dispersion are uniform Mix to obtain casting solution;

[0049] 3) Leave the casting solution to defoam for 24 hours and extrude the core solution from the spinning nozzle at the same time. The temperature of the spinning nozzle is 90°C. The casting solution passes through a distance of 50mm at a speed of 3m / min in the air and then solidifies. bath, stay in the coagulation bath for 15s, take it out, and obtain a hollow fiber ultrafiltration membrane 3 modified by graphene oxide gold nanoparticles; place it in an aqueous solution for rinsing for 24 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com