A kind of multifunctional ceramsite with the ability to supply alkali and release calcium, preparation method and application thereof

A multifunctional technology for calcium release from alkali, applied in the field of multifunctional ceramsite and its preparation, can solve problems such as secondary pollution, and achieve the effects of high utilization rate, good effect and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation and application process of the present invention are further illustrated below in conjunction with examples.

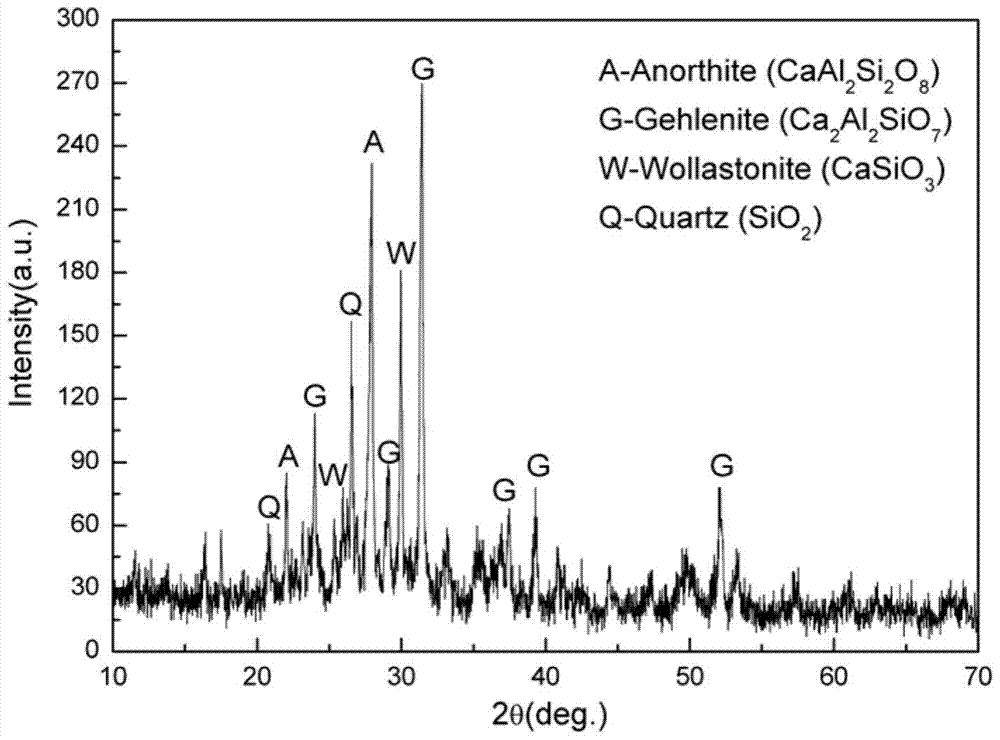

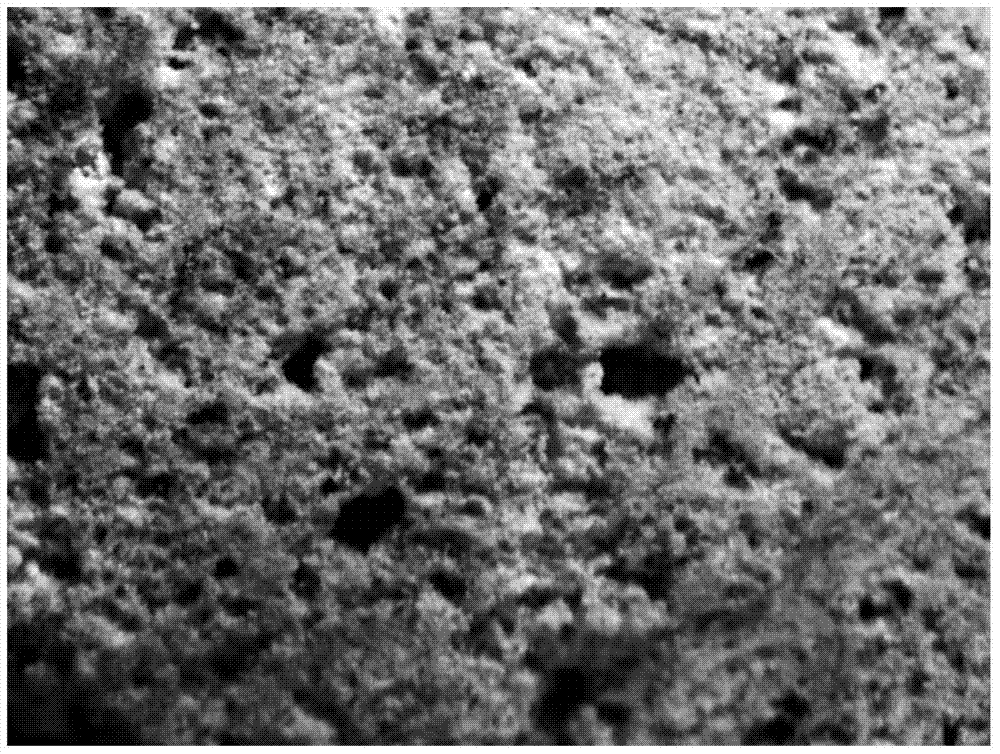

[0022] The principle of the present invention is: (1) obtaining the porosity of ceramsite. Calcium carbonate in papermaking lime mud is decomposed by heat at around 800°C, as shown in formula (a), producing a large amount of CO 2 The gas escapes continuously, forming connected pores in the range of 5-15 μm inside the ceramsite, and the organic wood chips in the raw material are burned out during the calcination process to form large pores in the range of 100-200 μm in the ceramsite. The pore size in the ceramsite is Bimodal distribution. (2) Low-temperature calcination mechanism of ceramsite. The mixture of raw materials such as papermaking lime mud and fly ash belongs to CaO-Al 2 o 3 -SiO 2 system, after calcination at 950-1100°C, anorthite (CaAl 2 Si 2 o 8 ), calcium aluminate feldspar (Ca 2 Al 2 SiO 7 ), wollastonite (CaSiO 3 ) an...

Embodiment 1

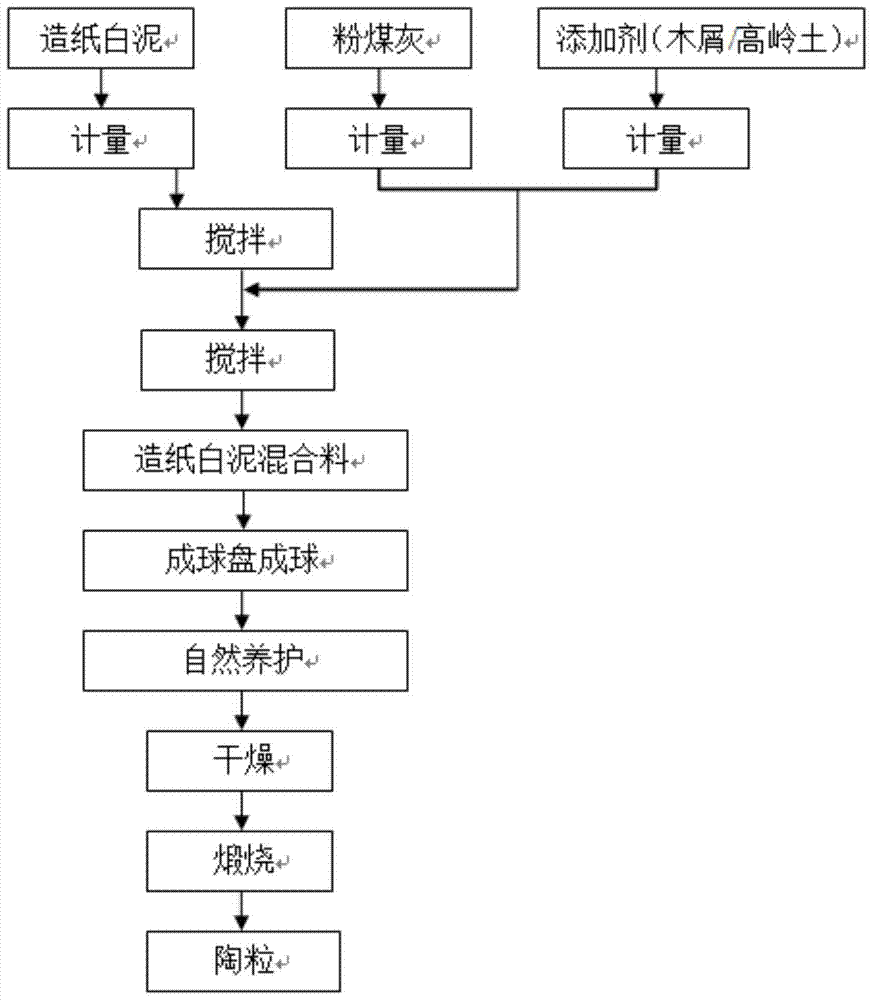

[0034] Example 1: Combining figure 1 , the preparation and application of a kind of multifunctional ceramsite with the ability to release calcium for alkali in the present invention are as follows:

[0035] The ground raw materials are weighed and stirred according to the mass percentage of papermaking white mud: fly ash: wood chips: kaolin = 36:53:10:1, and the water-solid ratio is 0.1; put the evenly stirred mixture into a ball Granulate in a pan to make pellets with a particle size of 2-5 mm; place the pellets at room temperature for 24 hours for natural curing; put the pellets after natural curing in a preheating kiln for drying; dry the pellets after drying The balls are put into the roasting kiln for calcination. The calcination temperature is 1100°C. The heating rate is first raised from room temperature to 800°C at 10°C / min, and then continued to rise to 1100°C at 5°C / min after holding for 1 hour, and the heat preservation rate is 0.5°C. Cool in the furnace after 1 ho...

Embodiment 2

[0037] Example 2: Combining figure 1 , the preparation and application of a kind of multifunctional ceramsite with the ability to release calcium for alkali in the present invention are as follows:

[0038] The ground raw materials are weighed according to the mass percentage of papermaking white mud: fly ash: wood chips: kaolin = 42:44:7:7, and the water-solid ratio is 0.07; put the evenly stirred mixture into a ball Granulate in a pan to make pellets with a particle size of 2-5 mm; place the pellets at room temperature for 24 hours for natural curing; put the pellets after natural curing in a preheating kiln for drying; dry the pellets after drying The balls are put into the roasting kiln for calcination, the calcination temperature is 1050°C, the heating rate is first raised from room temperature to 800°C at 10°C / min, and then continued to rise to 1050°C at 5°C / min after holding for 1 hour. Cool in the furnace after 1 hour.

[0039] The bulk density of the ceramsite is 64...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com