Nano-gold coated layered double hydroxide composite material and its preparation and application

A double hydroxide, composite material technology, applied in the direction of drug combination, medical preparations containing active ingredients, organic active ingredients, etc., can solve the problems of weak curative effect, poor drug availability, low targeting, etc. Circulation time in vivo, effect of high drug load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of nano-gold coated layered double hydroxide composite material adopts the following steps:

[0038] (1) Preparation of nano-layered double hydroxide

[0039] a. Prepare a solution containing divalent metal ion salt and trivalent metal ion salt, the molar ratio between divalent metal ion salt and trivalent metal ion salt is 1:3;

[0040] b. Configure NaOH solution and 2 Stir at 60°C for 10 minutes under atmosphere;

[0041] c. Add the step a solution dropwise to the step b solution, N 2 Stirring was continued at 60°C for 3 h under atmosphere;

[0042] d. Take out the sample obtained after the reaction, wash it repeatedly with double distilled water after centrifugation and centrifuge it for 3 times, then put it in a hydrothermal kettle, and react at 100°C for 16h;

[0043] e. Centrifuge the obtained sample, remove the supernatant, place it in a vacuum drying oven at 50° C. for 48 hours and take it out after completely drying it, place it in a ...

Embodiment 1

[0052] Preparation of Nanolayered Double Hydroxide

[0053] Step a: Preparation of MgCl 2 ·6H 2 O (0.6099g, 0.003mol) and AlCl 3 9H 2 O (0.2414g, 0.001mol) metal mixed salt solution total 10mL

[0054] Step b: 40 mL of NaOH solution with a concentration of 0.0006 mol was placed in N 2 Stir at 60°C for 10 minutes under atmosphere

[0055] Step c: Add the solution of step a dropwise to the solution of step b, N 2 Stir at 60°C for 3 hours under atmosphere.

[0056] Step d: Take out the sample after the reaction, centrifuge, use ddH 2 O water was repeatedly washed and centrifuged three times, transferred to a hydrothermal kettle, placed in an oven, and reacted at 100°C for 16 hours.

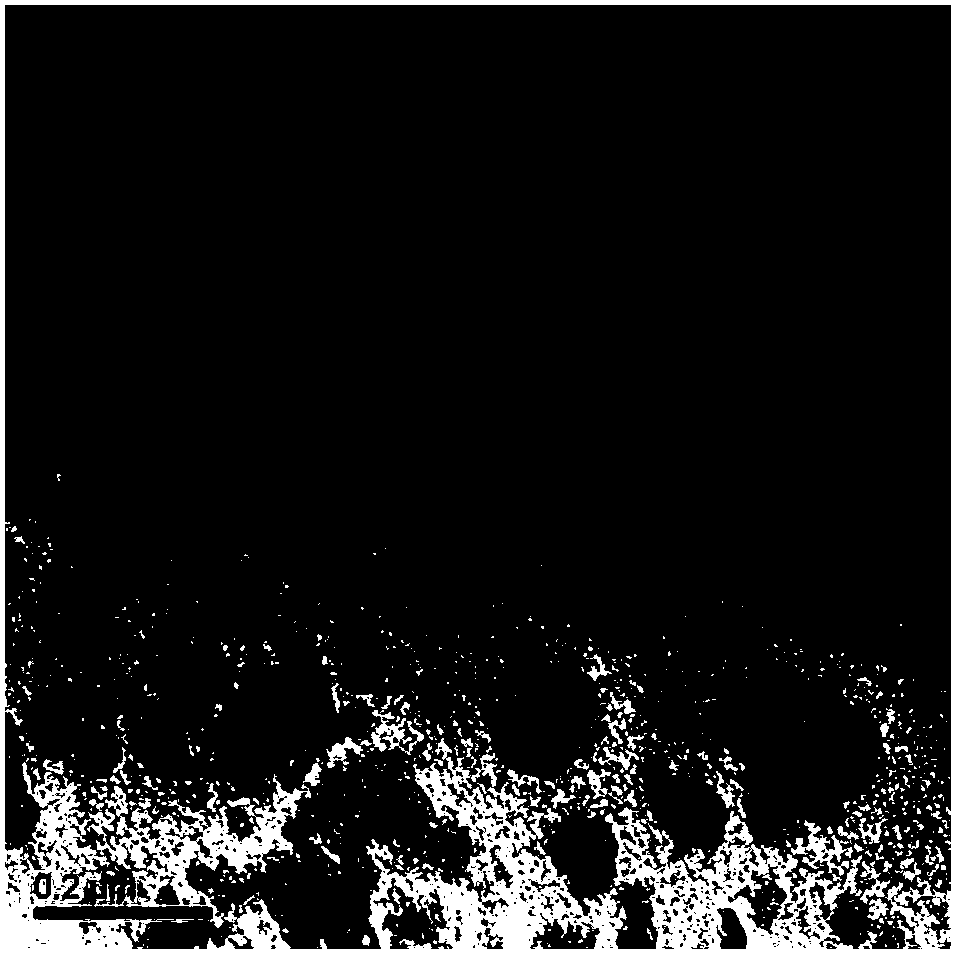

[0057] Step e: Centrifuge the sample, pour off the supernatant, put it in a vacuum drying oven at 50°C for 48 hours, take it out, and grind it into powder in a mortar to obtain the sample. The electron microscope morphology is as follows figure 1 shown.

Embodiment 2

[0059] Preparation of gold nanoparticles.

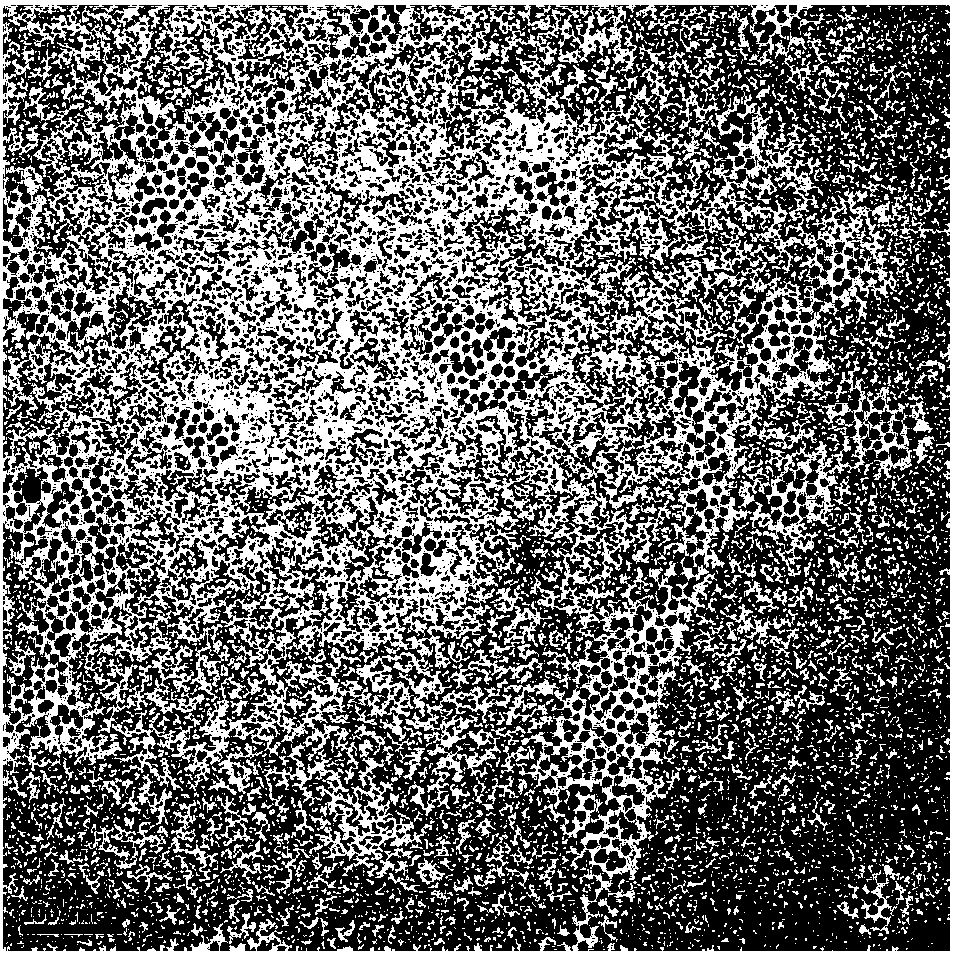

[0060] Prepare tetra-n-octylammonium bromide (136.7mg, 0.25mmol), dodecylamine (111.2mg, 0.6mmol), and chloroauric acid (218.3mg, 0.53mmol) in 5mL of toluene. At room temperature, sodium borohydride (75.6 mg, 2 mmol) was added to the vigorously stirred solution above, and after 2 hours, high-speed centrifugation was performed to obtain oil-soluble gold nanoparticles. Dissolve the obtained nano-gold in 3 mL of chloroform, modify the surface of nano-gold with functionalized polyethylene glycol HS-PEG-COOH (molecular weight 2000 g / mol, 80 mg, 40 μmol) containing mercapto and carboxyl groups, and react at room temperature for 24 hours to obtain The stable 5nm nano-gold system in the water phase is used to interact with LDH, and its electron microscope morphology is as follows figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com