Au@Cu2-deltaX nanoscale crystal and preparation method and application thereof

A nanocrystal, aucu2- technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as low absorption of sulfides, reduced photothermal conversion efficiency, etc., and achieve mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

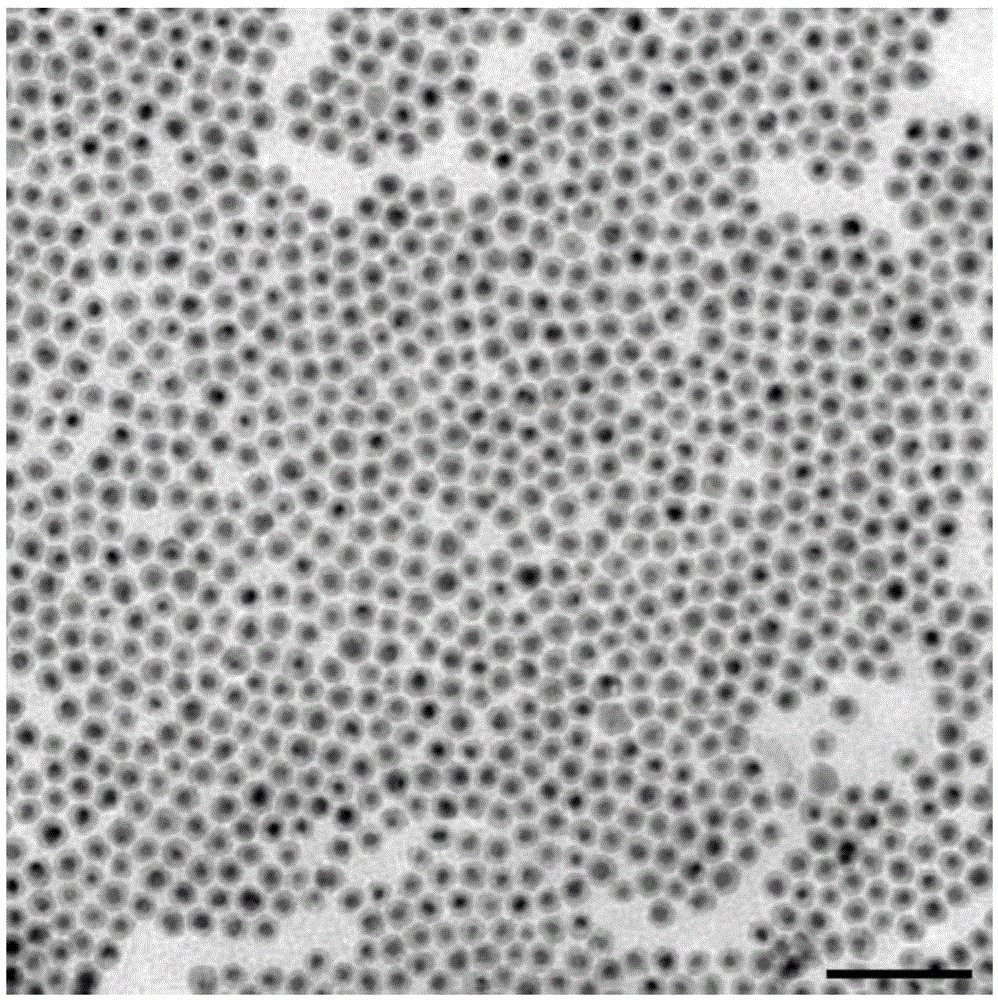

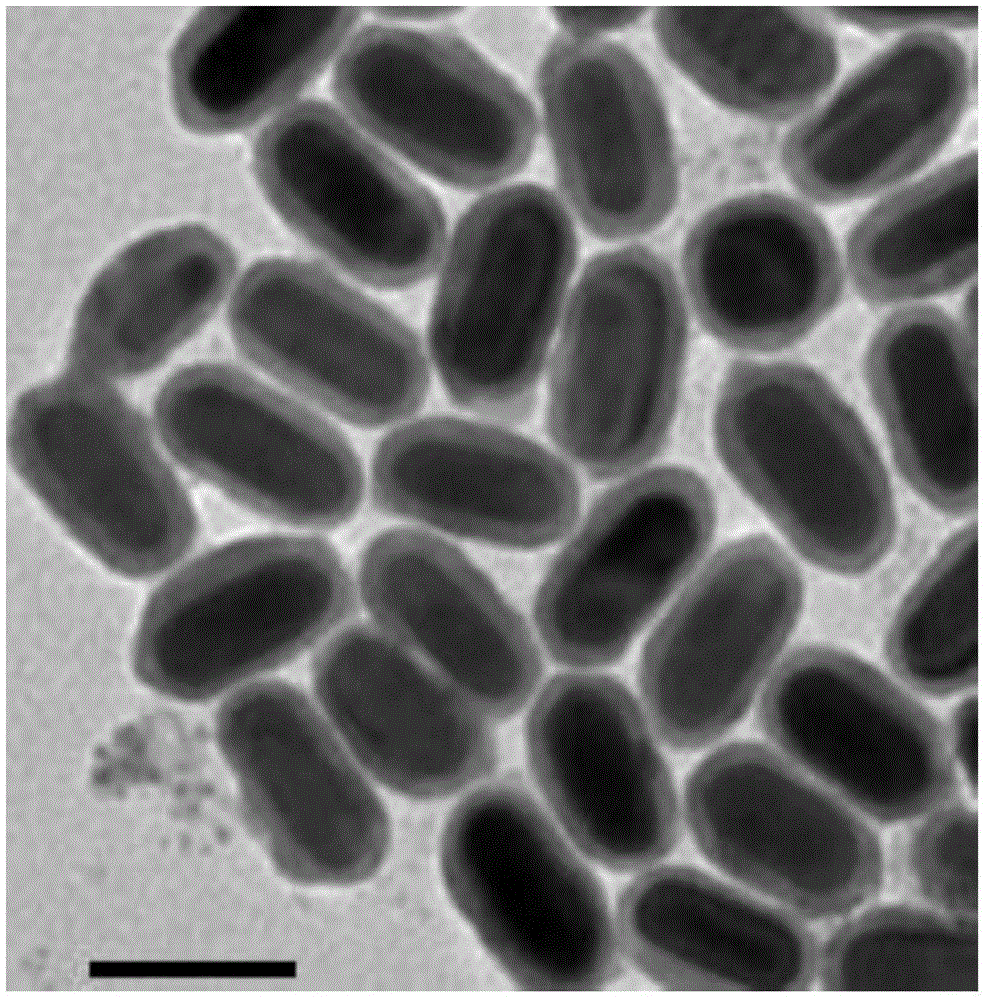

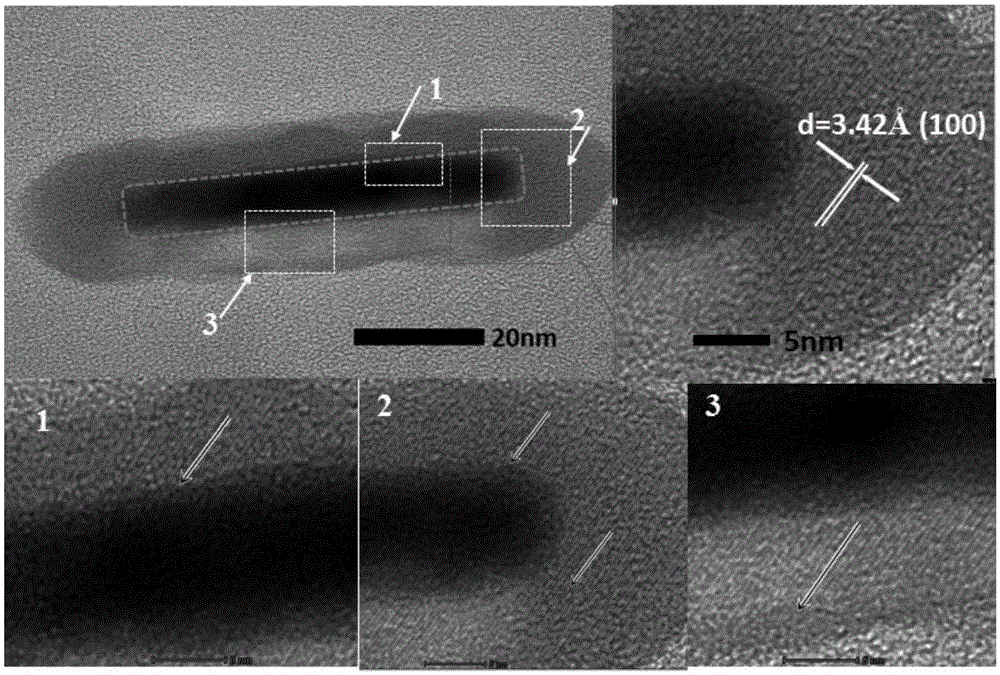

[0063] 1. Preparation of granular AuCdS nanocrystals

[0064] (1) Stir 0.72mL of oleic acid, 1mL of 1mol / L sodium hydroxide solution, 4mL of acetonitrile and 4mL of water at room temperature, then add chloroauric acid (HAuCl 4 4H 2 (2) 20 mg, stirred to form a uniform transparent microemulsion, added 80 μL of 0.1mol / L ascorbic acid solution and 13 mL of cyclohexane, and continued to stir for 6 h, left to stand, after layering, take the organic layer liquid; add ethanol to the organic layer liquid 39mL, and centrifuged at 2000rpm for 7min to obtain 4nm granular Au nanocrystals;

[0065] (2) Disperse the granular Au nanocrystals in 20mL of toluene to obtain the granular Au nanocrystal sol, the concentration is 1mg / mL, take the granular Au nanocrystal sol 8mL, add 0.2mL of oleylamine, silver nitrate methanol of 10mg / mL After 1mL of the solution, seal it in a 20mL screw bottle, heat it in an oil bath to 60°C, and keep the temperature constant for 16h to obtain a granular AuAg na...

Embodiment 2

[0079] 1. Preparation of granular AuCdS nanocrystals

[0080] (1) At room temperature, stir 0.72mL of oleic acid, 1mL of 1mol / L sodium hydroxide solution, 4mL of acetonitrile and 4mL of water evenly, then add 20mg of chloroauric acid and stir to form a uniform and transparent microemulsion, add 0.1mol / L 80μL of ascorbic acid solution and 13mL of cyclohexane, and continue to stir for 6h, add 4mg of chloroauric acid, 40μL of 0.1mol / L ascorbic acid solution, continue to stir for 3h; stand still, take the organic layer liquid after layering; add to the organic layer liquid 39 mL of absolute ethanol, and centrifuged at 2000 rpm for 7 min to obtain 5 nm granular Au nanocrystals;

[0081] (2) Disperse the granular Au nanocrystals in 40mL of toluene to obtain the granular Au nanocrystal sol, the concentration is 1mg / mL, take the granular Au nanocrystal sol 8mL, add 0.2mL of oleylamine, silver nitrate methanol of 10mg / mL After the solution was 1 mL, it was sealed in a 20 mL capacity s...

Embodiment 3

[0095] 1. Preparation of granular AuCdS nanocrystals

[0096] (1) At room temperature, stir 0.72mL of oleic acid, 1mL of 1mol / L sodium hydroxide solution, 4mL of acetonitrile and 4mL of water evenly, then add 30mg of chloroauric acid and stir to form a uniform and transparent microemulsion, add 0.1mol / L 80 μL of ascorbic acid solution and 13 mL of cyclohexane, and continue to stir for 6 hours, add 8 mg of chloroauric acid, 40 μL of 0.1 mol / L ascorbic acid solution, continue to stir for 3 hours, stand still, take the organic layer liquid after layering; add to the organic layer liquid Ethanol 39mL, and centrifuged at 2000rpm for 7min to obtain 8nm granular Au nanocrystals;

[0097] (2) Disperse the granular Au nanocrystals in 30mL of toluene to obtain the granular Au nanocrystal sol, the concentration is 1mg / mL, take the granular Au nanocrystal sol 8mL, add 0.2mL of oleylamine, silver nitrate methanol of 10mg / mL After 1mL of the solution, seal it in a 20mL screw bottle, heat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com