Anatase phase titanium dioxide nanosheet array preparing method

A nanosheet array and titanium dioxide technology, which is applied in the field of nanotechnology material synthesis, can solve the problems of inability to obtain high photoelectric conversion efficiency, small specific surface area of nanosheet films, and difficulty in preparing photovoltaic cell devices, and achieves the advantages of device preparation and orientation. Consistent, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

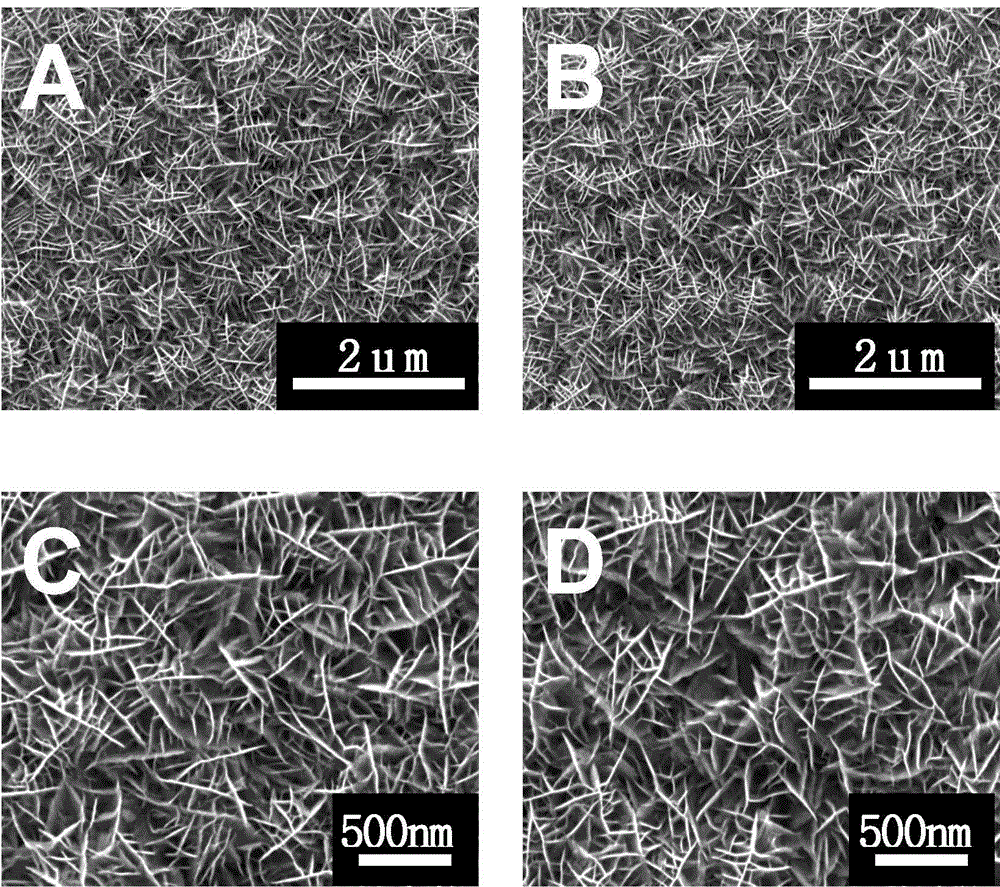

Image

Examples

Embodiment 1

[0023] Titanium isopropoxide is dissolved in a mixed solvent composed of triethanolamine and water, the molar ratio of titanium isopropoxide, triethanolamine, and water is 1:48:2514, and the concentration of disodium edetate is 0.6mol / L. The concentration of trisodium citrate is 0.4mol / L, heated and stirred at 50°C for 15 minutes, and prepared as a reaction solution containing titanium precursor;

[0024] The tin-doped indium oxide glass was ultrasonically cleaned in acetone, isopropanol, absolute ethanol and deionized water for 15 minutes in sequence, and dried, and placed in a hydrothermal reaction kettle, and the titanium precursor reaction solution was added to the reaction kettle, 200 The reaction was heated at ℃ for 9 hours. After the reaction was completed, the conductive glass substrate was taken out from the reaction kettle, rinsed, and dried to obtain a sodium titanate nanosheet array film;

[0025] The titanate nanosheet array was cation-exchanged with 0.2mol / L dilu...

Embodiment 2

[0028] Dissolve tetra-n-butyl titanate in a mixed solvent composed of triethanolamine and water, the molar ratio of titanium isopropoxide, triethanolamine, and water is 1:16:838, and the concentration of disodium edetate is 0.1mol / L, the concentration of sodium oxalate is 0.2mol / L, heated and stirred at 60°C for 20min, and made into a reaction solution containing titanium precursor;

[0029] The fluorine-doped tin oxide glass was ultrasonically cleaned in acetone, isopropanol, absolute ethanol, and deionized water for 20 minutes in sequence, and dried, and placed in a hydrothermal reaction kettle, and the titanium precursor reaction solution was added to the reaction kettle, and the reaction solution was 210 ℃ for heating and reacting for 15 hours. After the reaction was completed, the conductive glass substrate was taken out from the reaction kettle, rinsed, and dried to obtain a sodium titanate nanosheet array film;

[0030] The titanate nanosheet array was cation-exchanged...

Embodiment 3

[0033] Dissolve tetra-n-butyl titanate in a mixed solvent composed of triethanolamine and water, the molar ratio of titanium isopropoxide, triethanolamine, and water is 1:4:111, and the concentration of disodium edetate is 0.9mol / L, the concentration of disodium phthalate is 0.5mol / L, heated and stirred at 70°C for 30min, and made into a reaction solution containing titanium precursor;

[0034] The tin-doped indium oxide glass was ultrasonically cleaned in acetone, isopropanol, absolute ethanol and deionized water for 30 minutes in sequence, and dried, and placed in a hydrothermal reaction kettle, and the titanium precursor reaction solution was added to the reaction kettle, 220 The reaction was heated at ℃ for 24 hours. After the reaction was completed, the conductive glass substrate was taken out from the reaction kettle, rinsed, and dried to obtain a sodium titanate nanosheet array film;

[0035] The titanate nanosheet array was cation-exchanged with 0.6mol / L dilute hydroc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com