Nickel manganese/carbon nanotube composite catalyst and preparation and application thereof

A carbon nanotube composite and carbon nanotube technology, which is applied to functional catalysts and their preparation and application fields, can solve the problems of limiting metal-air battery efficiency, unfavorable industrial-scale preparation, complex catalyst preparation process, etc., and achieves excellent charge-discharge performance. and stability, excellent electrochemical performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

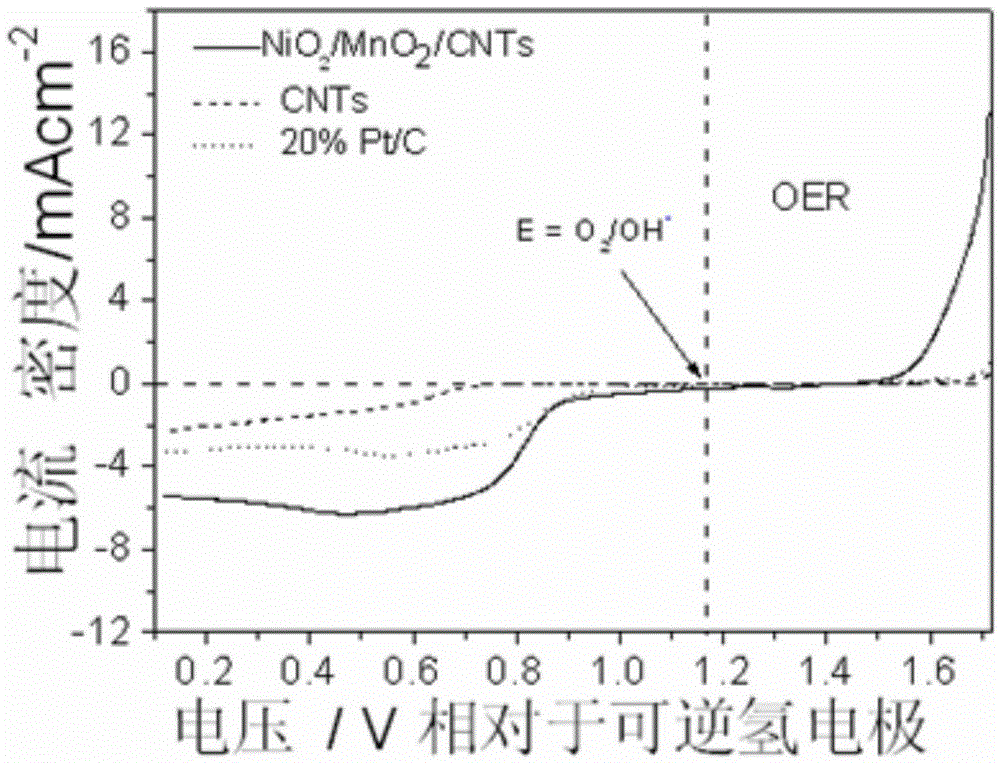

[0032] Bifunctional catalysts, including carbon nanotubes and nickel manganese oxide (NiMnO 4 ) spinel. The nickel manganese oxide (NiMnO 4 ) spinel is a nano particle with a diameter of 20-150nm, and is uniformly loaded on the carbon nanotube.

[0033] The preparation method of catalyst is:

[0034] The first step: configure the potassium permanganate solution that the mass ratio of potassium permanganate and water is 1.4g:100, add the concentrated hydrochloric acid that potassium permanganate solution and concentrated hydrochloric acid ratio are 101.4g:4ml to the high In the potassium manganate solution, continue to stir until the mixture is uniform, transfer the resulting mixture to an autoclave at 145°C for a hydrothermal reaction for 10 hours, cool to room temperature, wash with ethanol and deionized water for 5 times, and then dry at 80°C In 24 hours, the manganese dioxide precursor was obtained;

[0035]Step 2: Weigh 0.125g of the above-mentioned manganese dioxide p...

Embodiment 2

[0040] Bifunctional catalysts, including carbon nanotubes and nickel manganese oxide (NiMnO 4 ) spinel. The nickel manganese oxide (NiMnO 4 ) spinel spinel is a nano particle with a diameter of 20-150nm, and is uniformly loaded on carbon nanotubes.

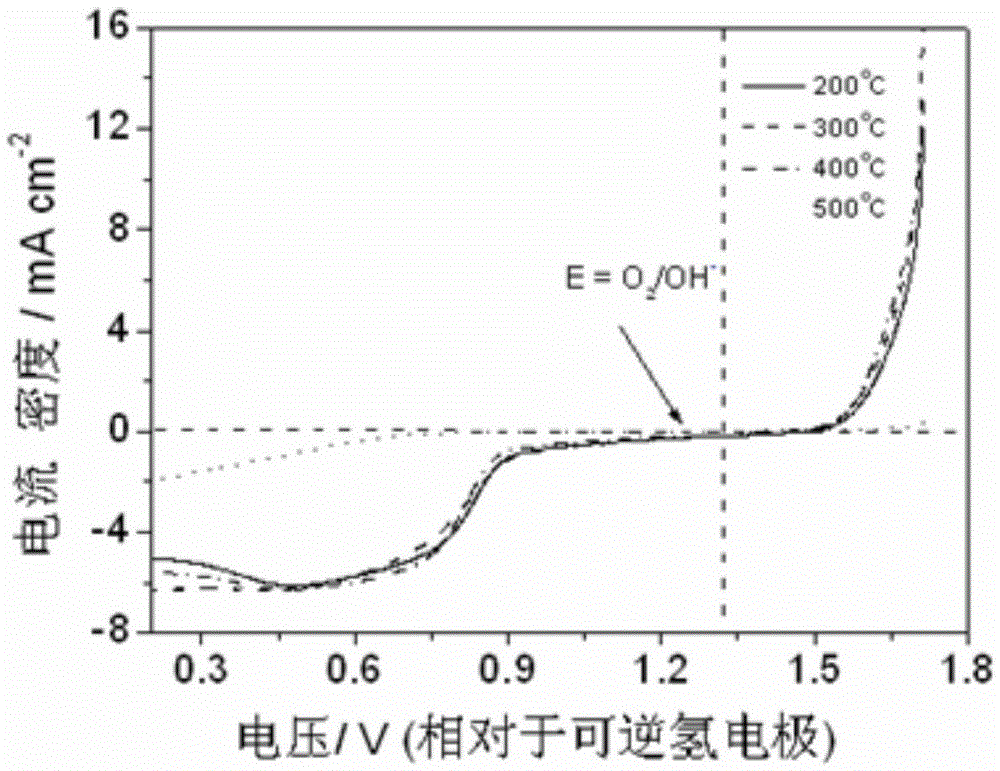

[0041] Preparation of catalytic composites at different calcination temperatures:

[0042] The first step: configure the potassium permanganate solution that the mass ratio of potassium permanganate and water is 1.4g:100, add the concentrated hydrochloric acid that potassium permanganate solution and concentrated hydrochloric acid ratio are 101.4g:4ml to the high In the potassium manganate solution, continue to stir until the mixture is uniform, transfer the resulting mixture to an autoclave at 145°C for a hydrothermal reaction for 10 hours, cool to room temperature, wash with ethanol and deionized water for 5 times, and then dry at 80°C In 24 hours, the manganese dioxide precursor was obtained;

[0043] Step 2: Weigh 0.125g o...

Embodiment 3

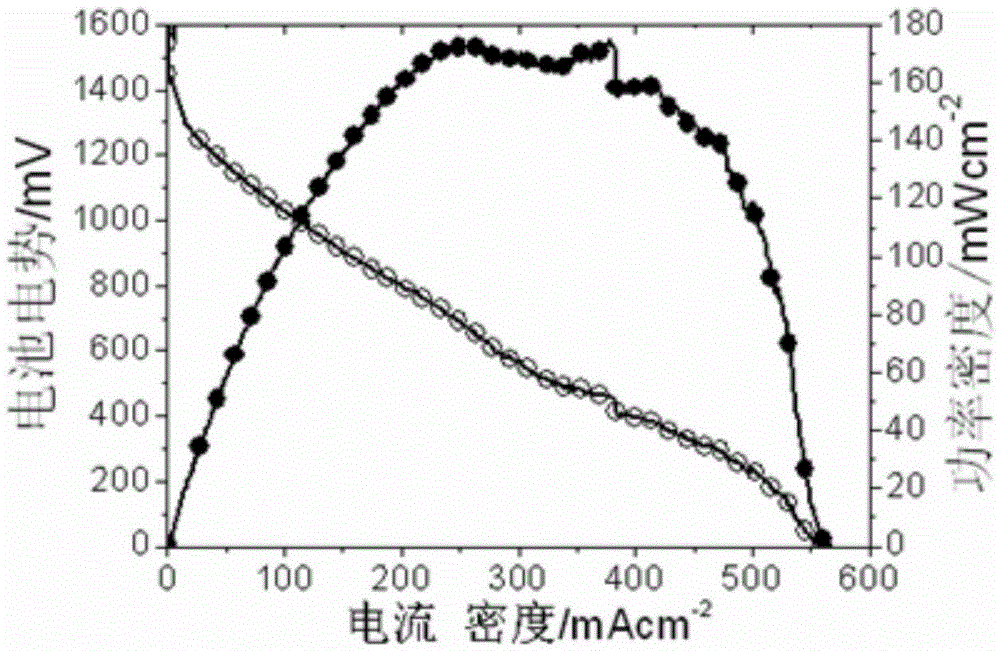

[0048] The catalyst powder of the embodiment 1 of 5mg is dissolved in the 5% Nafion solution of 1ml ethanol and 8 μ l, forms homogeneous catalyst slurry by ultrasonic 40 minutes, then sprays on the carbon paper through hydrophobic treatment, and the control catalyst load is 2mg / cm 2 The air electrode was prepared by drying at 60°C for 40 minutes. At the same time, the zinc foil with the same area as the carbon paper was used as the negative electrode. Batteries, tested using the Gradient Current Mode using the fuel cell activation system:

[0049] At normal temperature and pressure, test the power generation curve and polarization curve such as image 3 As shown, it can be seen that the open circuit voltage of a single cell can reach 1395mV, and the maximum power generation density can reach 172mW / cm 2 . When the voltage is 1V, the current density is 135.9mAcm -2 , the corresponding power generation density reaches 135.9mW / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com