Polycrystalline silicon wafer texturing auxiliary and application method thereof

A polycrystalline silicon wafer and application method technology, applied in the field of solar cells, can solve problems such as difficulty in adapting to polycrystalline silicon wafers, sensitive surface conditions of silicon wafers, large equipment investment, etc., so as to improve experimental repeatability, improve texturing uniformity, and improve texturing. The effect of surface uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Configure the texturing liquid: the proportion and method are the same as in Comparative Example 1.

[0040] 2) Prepare auxiliary agent: Add 10% hydrogen peroxide by volume, 0.1mol / L silver nitrate, 1% ammonium fluoride by mass and 100ppm ethylene glycol in deionized water in sequence, and stir evenly to prepare auxiliary agent .

[0041] 3) Texturing: Add 1% volume ratio auxiliary agent to the texturing liquid and stir evenly, immerse the polysilicon wafer cut by the mortar into the texturing liquid, control the temperature at 30°C, and the reaction time is 240s. After the reaction was completed, the silicon wafer was immersed in an aqueous sodium hydroxide solution with a temperature of 25°C and a mass concentration of 0.5% to remove the porous structure on the surface for 180 s.

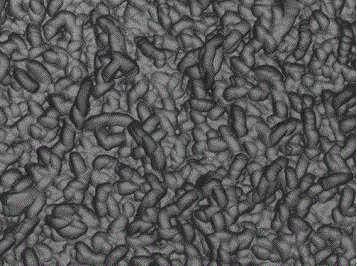

[0042]After the texturing is completed, the silicon wafer is cleaned and dried, and its surface reflectance is measured to be about 8%. The photo of its surface morphology is as follows...

Embodiment 2

[0044] 1) Configure the texturing liquid: the proportioning and method are the same as in Comparative Example 1.

[0045] 2) Preparation of auxiliary agents: Add 15% volume ratio of hydrogen peroxide, 0.2mol / L silver nitrate, 1% mass ratio of ammonium bifluoride and 100ppm ethylene glycol in deionized water in sequence, and stir evenly to prepare auxiliary agents.

[0046] 3) Texturing: add 2% volume ratio of auxiliary agent to the texturing liquid and stir evenly, immerse the diamond wire-cut polysilicon wafer in the texturing liquid, the temperature is controlled at 40°C, and the reaction time is 300s. After the reaction was completed, the silicon wafer was immersed in a sodium hydroxide solution with a temperature of 25 °C and a mass concentration of 1% to remove the porous structure on the surface for 240 s.

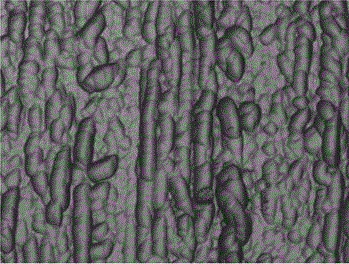

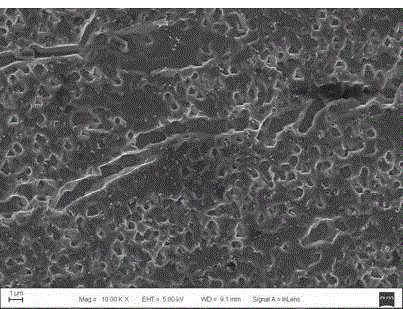

[0047] After the texturing is completed, the silicon wafer is cleaned and dried, and its surface reflectance is measured to be about 15%, and its appearance is as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com