Preparation method and application of polycarboxylate water reducer containing phosphate groups

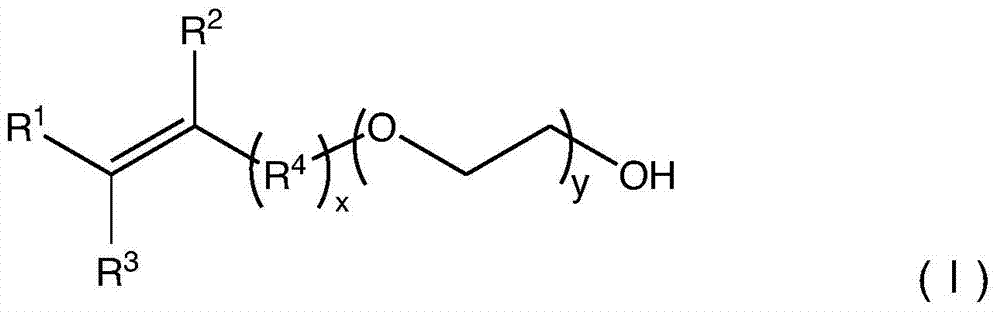

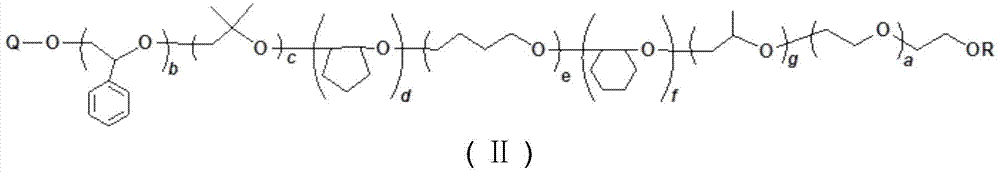

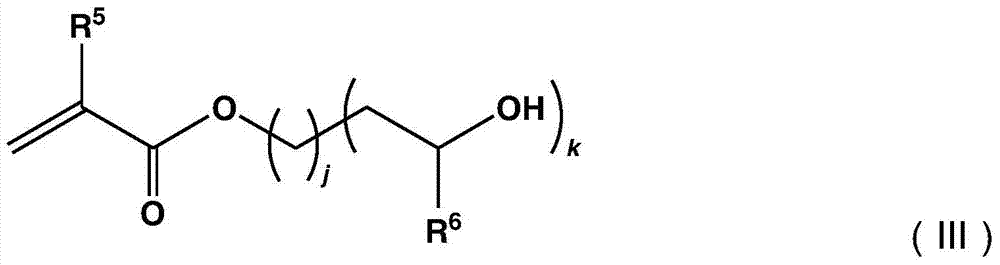

A phosphate-based, polycarboxylic acid technology, applied in the field of concrete admixtures, can solve the problems of inability to accurately control the structure and molecular weight of the water-reducing agent, cumbersome steps, and low water-reducing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Synthesis of methyl-terminated polyether with a molecular weight of 2006.

[0060] Polyether preparation:

[0061] The initiator is allyl alcohol, and the catalyst is sodium methoxide. Weigh 58g (1mol) of allyl alcohol and 3g of sodium methoxide, put the above materials into the reactor, and vacuumize the reactor to -0.1MPa at room temperature. Then the temperature of the reaction kettle was raised to 100° C., and 50 g of ethylene oxide was introduced into the reaction kettle. When the pressure in the reaction kettle dropped and the temperature rose, it indicated that the polymerization reaction started. Continue to feed 1892g of ethylene oxide into the reactor. During the feeding process, keep the temperature of the reactor between 100-120°C and the pressure between 0.2-0.4MPa. After the addition of ethylene oxide is completed, keep the temperature at 100°C for about 1h . When the pressure of the reactor no longer decreases, reduce the temperature of the reactor to ...

Embodiment 2

[0072] Synthesis of a methyl-terminated block polyether with a molecular weight of 4800.

[0073] Polyether preparation:

[0074] Initiator 10-undecenol, catalyst sodium hydride (60%). Weigh 85 g (0.5 mol) of 10-undecenol and 2 g of sodium hydride, put the above materials into the reactor, and vacuumize the reactor to -0.1 MPa at room temperature. Then the temperature of the reaction kettle is raised to 100°C, and 82.86g of epoxycyclohexane is passed into the reaction kettle. When the pressure in the reaction kettle drops and the temperature rises, it indicates that the polymerization reaction starts. The internal pressure no longer drops. Then continuously feed 2232.14g of ethylene oxide into the reactor, keep the temperature of the reactor between 100-120°C and the pressure between 0.2-0.4MPa during the feeding process, and keep the temperature at 100°C after the feeding of ethylene oxide is completed About 1h. When the pressure of the reactor is no longer reduced, reduc...

Embodiment 3

[0081] Synthesis of polycarboxylate superplasticizer prepolymer:

[0082] Add 200g (0.1mol) of unsaturated polyether M1, 21.5g (0.25mol) of methyl acrylate, 0.058g (0.001mol) of allyl alcohol into a glass reaction flask equipped with a thermometer, stirrer, and peristaltic pump feeding system , while adding 44g of petroleum ether, heating up to 30°C to dissolve while stirring, then adding 1.15g (0.007mol) of azobisisobutyronitrile, and stirring evenly. Then weigh 0.14g (0.0018mol) of mercaptoethanol, add it to 22g of petroleum ether, stir to make a uniform solution, and use the peristaltic pump feeding system to drop it into the reaction bottle at a constant speed. The dropping time is 2h, and the dropping is completed. After incubation, the reaction was carried out for 2 hours. Tested by GPC, the molecular weight is 25000, and the molecular weight distribution is 1.71.

[0083] Phosphorylation modification:

[0084] Weigh 0.12g (0.00102mol) of 85% phosphoric acid and 0.22g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com