Organic solar cell with nano-particle close-packed structure

An organic solar cell, nanoparticle technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as low carrier mobility, low utilization of solar spectrum, constraints, etc. Achieve the effects of high carrier mobility, expanded selection range, and high absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation of an inverted organic solar cell with a nanoparticle close-packed structure, the specific process is as follows:

[0023] 1. The ITO glass is ultrasonically cleaned with electronic cleaning solution / deionized water / alcohol / acetone / isopropanol in sequence, and blown dry with nitrogen.

[0024] 2. Spin-coat a zinc oxide (ZnO) electron transport layer with a thickness of 30nm on the ITO glass, and anneal at 200°C for one hour.

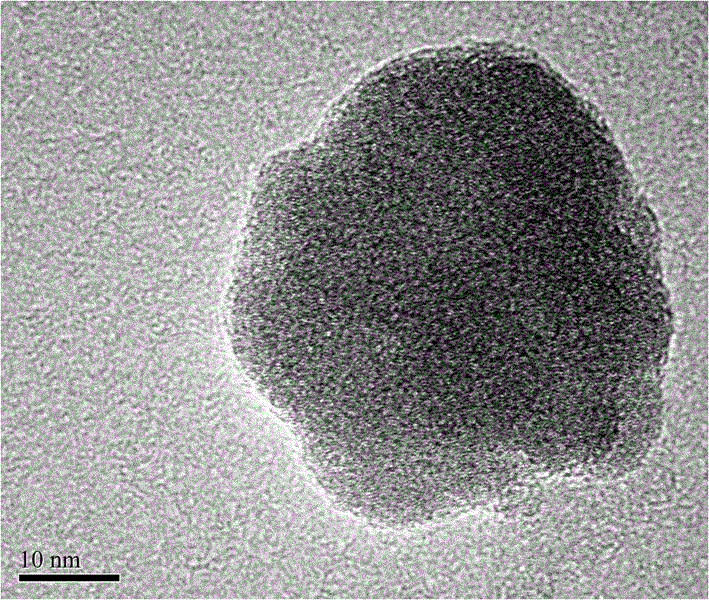

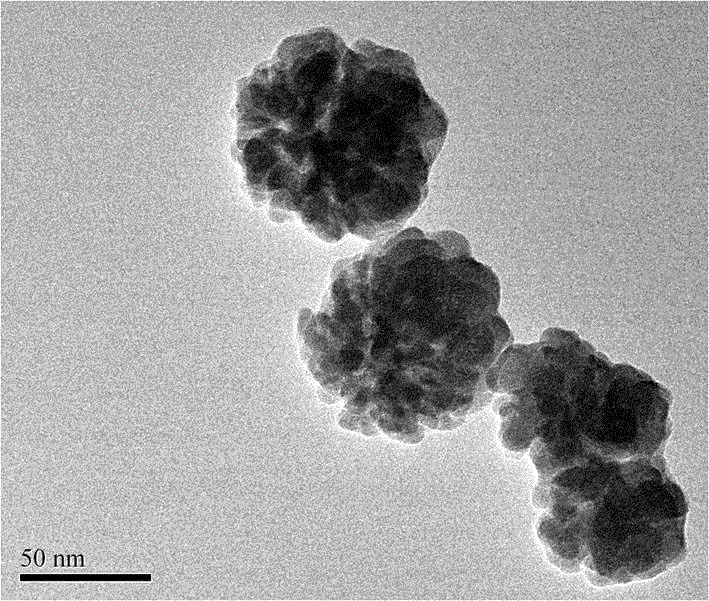

[0025] 3. Prepare spherical germanium nanoparticles with a diameter of 40-100nm, hydrogen bond passivation on the surface, under low temperature conditions by using flat plate capacitively coupled PECVD technology.

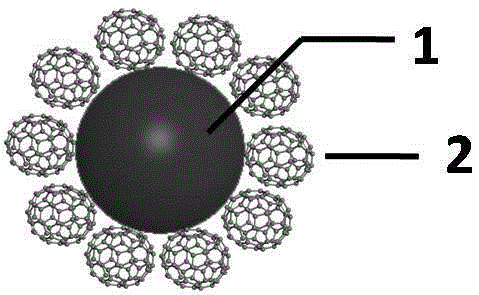

[0026] 4. The germanium nanoparticles were dispersed in 1,2-dichlorobenzene to form a colloidal solution with a concentration of 5 mg / mL; the PC 70 BM was dissolved in the colloidal solution, heated and stirred at 90°C for 12 hours to form a stable active layer solution.

[0027] 5. Spin-coat an active layer with a t...

Embodiment 2

[0031] The preparation of positive structure organic solar cells with nanoparticle close-packed structure, the specific process is as follows:

[0032] 1. The ITO glass is ultrasonically cleaned with electronic cleaning solution / deionized water / alcohol / acetone / isopropanol in sequence, and blown dry with nitrogen.

[0033]2. Spin-coat a layer of poly(3,4-hexenedioxythiophene)-polystyrenesulfonic acid (PEDOT:PSS) hole transport layer with a thickness of 40nm on the ITO glass, and anneal at 100°C for 10 minutes .

[0034] 3. Prepare spherical germanium nanoparticles with a diameter of 40-100nm, hydrogen bond passivation on the surface, under low temperature conditions by using flat plate capacitively coupled PECVD technology.

[0035] 4. The germanium nanoparticles were dispersed in 1,2-dichlorobenzene to form a colloidal solution with a concentration of 5 mg / mL; the PC 70 BM was dissolved in the colloidal solution, heated and stirred at 90°C for 12 hours to form a stable activ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com