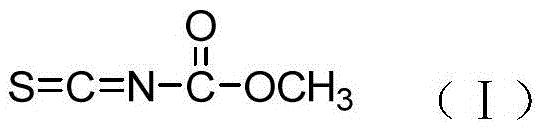

Method for preparing isothiocyano methyl formate

A technology of methyl formate and isothiocyanate, which is applied in the field of preparation of methyl isothiocyanate, can solve the problems of long reaction time, cumbersome operation, and high water requirement, so as to improve reaction safety and reduce reaction by-products , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Preparation of solid catalyst polyvinyl chloride supported N-alkyl-N-methylaniline (MA-PVC solid catalyst for short)

[0023] Install a stirrer, a reflux condenser, a thermometer, and an air guide tube on a 100mL four-necked reaction bottle. Under nitrogen protection, add 30.0gNaH (petroleum ether was used to wash away the mineral oil in advance), 300mL tetrahydrofuran (sodium metal-diphenyl Methanone was treated into a blue liquid and redistilled) and 50.9g (99%, 0.5mol) of N-methylaniline, heated to reflux, and a THF solution of 300g of PVC resin was added (PVC was dissolved in THF in advance and bubbled with nitrogen for 30min To remove the oxygen in the solution, containing 200g of PVC resin), the solution gradually turns brownish red, and the reaction is kept under reflux for 20h. Cool down, add water, filter out the catalyst, wash the catalyst once with 300g of water and once with 200mLTHF, and dry to obtain a solid catalyst polyvinyl chloride suppor...

Embodiment 2~28

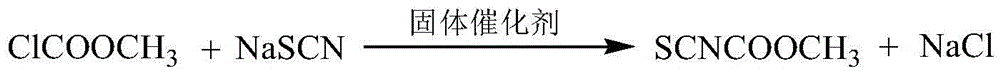

[0024] Embodiment 2~28 prepares methyl isothiocyanate

Embodiment 2

[0026] Pack 80 g of the MA-PVC solid catalyst prepared in Example 1 into a jacketed glass tubular reactor with a length of 80 cm and an inner diameter of 20 mm. The upper and lower ends of the catalyst are filled with magnetic rings, and the temperature of the jacket is controlled at 0°C. Utilize metering pump with 500.0g20.0% sodium thiocyanate aqueous solution (98.0%, 1.21mol, industrial product), 121.3g methyl chloroformate (99.0%, 1.27mol, industrial product) with 450.0g / h, 109.2 respectively g / h into the continuous reactor. Keep the feed rate and make the material stay in the reactor for 10min to obtain 142.5g of methyl isothiocyanate product, content 97.5% (GC, external standard method), yield 98.1% (calculated as sodium thiocyanate), catalyst can Continuous use for 300h, direct incineration after the catalytic effect declines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com