Preparation method of titanium-based conductive hydrogel composite coating material

A conductive hydrogel and composite coating technology, which is applied in the direction of electrolytic organic material coating, coating, polyether coating, etc., can solve the problems of carbon nanotubes and their composite materials that are difficult to disperse and easy to agglomerate, and achieve the goal of increasing the base The surface area and electrical conductivity of the material, the effect of high bonding strength and excellent coating bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] After the surface of titanium or titanium alloy is blasted, it is ultrasonically cleaned with ethanol, acetone and deionized water for 10 minutes, and then dried with nitrogen. After gold spraying treatment, ultrasonically clean with ethanol, acetone and deionized water respectively for 10 min, and blow dry with nitrogen gas. The dried titanium or titanium alloy was placed in 0.05mol / L dithiothreitol at 25°C for 5 hours, then dried with nitrogen and soaked in 0.05mol / L n-dodecanethiol at 25°C for 5 minutes, and washed with ethanol After 3 times, blow dry with nitrogen to obtain titanium or its alloy material grafted with mercapto groups on the surface.

Embodiment 2

[0032] After the surface of titanium or titanium alloy is blasted, it is ultrasonically cleaned with ethanol, acetone and deionized water for 10 minutes, and then dried with nitrogen. After gold spraying treatment, ultrasonically clean with ethanol, acetone and deionized water respectively for 10 min, and blow dry with nitrogen gas. The dried titanium or titanium alloy is placed in 60°C, 0.05mol / L dithiothreitol for 1 hour, then dried with nitrogen, soaked in 60°C, 0.05mol / L n-dodecanethiol for 5 minutes, and washed with ethanol After 3 times, blow dry with nitrogen to obtain titanium or its alloy material grafted with mercapto groups on the surface.

Embodiment 3

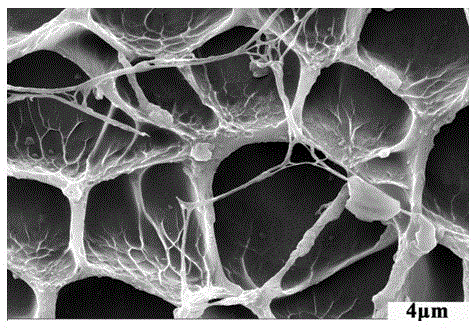

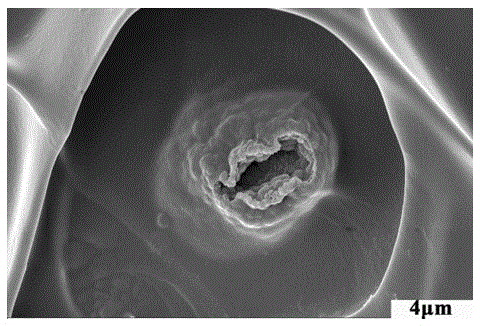

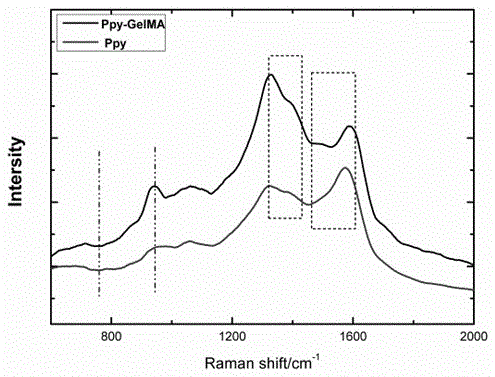

[0034] After the surface of titanium or titanium alloy is blasted, it is ultrasonically cleaned with ethanol, acetone and deionized water for 10 minutes, and then dried with nitrogen. After gold spraying treatment, ultrasonically clean with ethanol, acetone and deionized water respectively for 10 min, and blow dry with nitrogen gas. The dried titanium or titanium alloy was placed in 0.05mol / L dithiothreitol at 25°C for 5 hours, then dried with nitrogen and soaked in 0.05mol / L n-dodecanethiol at 25°C for 5 minutes, and washed with ethanol After 3 times, blow dry with nitrogen to obtain titanium or its alloy material grafted with mercapto groups on the surface. Prepare titanium or its alloy hydrogel coating by enol click reaction with Gelatinmethacrylate (GelMA) hydrogel under ultraviolet light, ultraviolet light for 30s, and ultraviolet light intensity 690mW / cm 2 , the photoinitiator is Igracure2959. Titanium or its alloy hydrogel coating is frozen and dried for 3D.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com