Preparation method and application of magnetic recyclable adsorbent

An adsorbent and magnetic technology, applied in the preparation of magnetic recyclable adsorbent and its application field, can solve the problems of small specific surface area, low adsorption capacity, poor selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

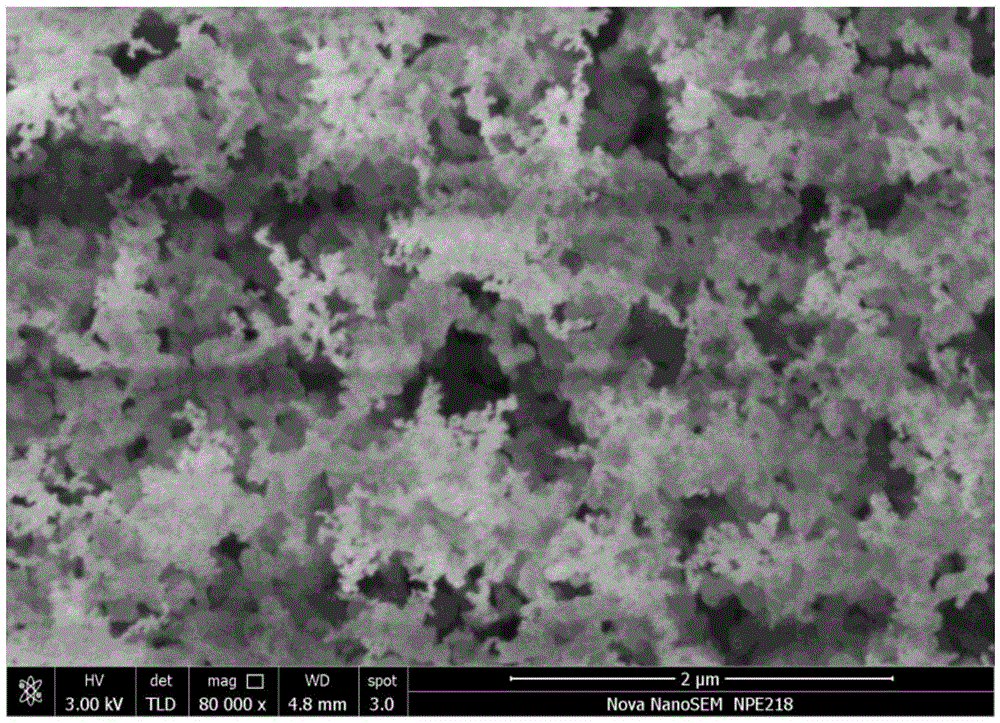

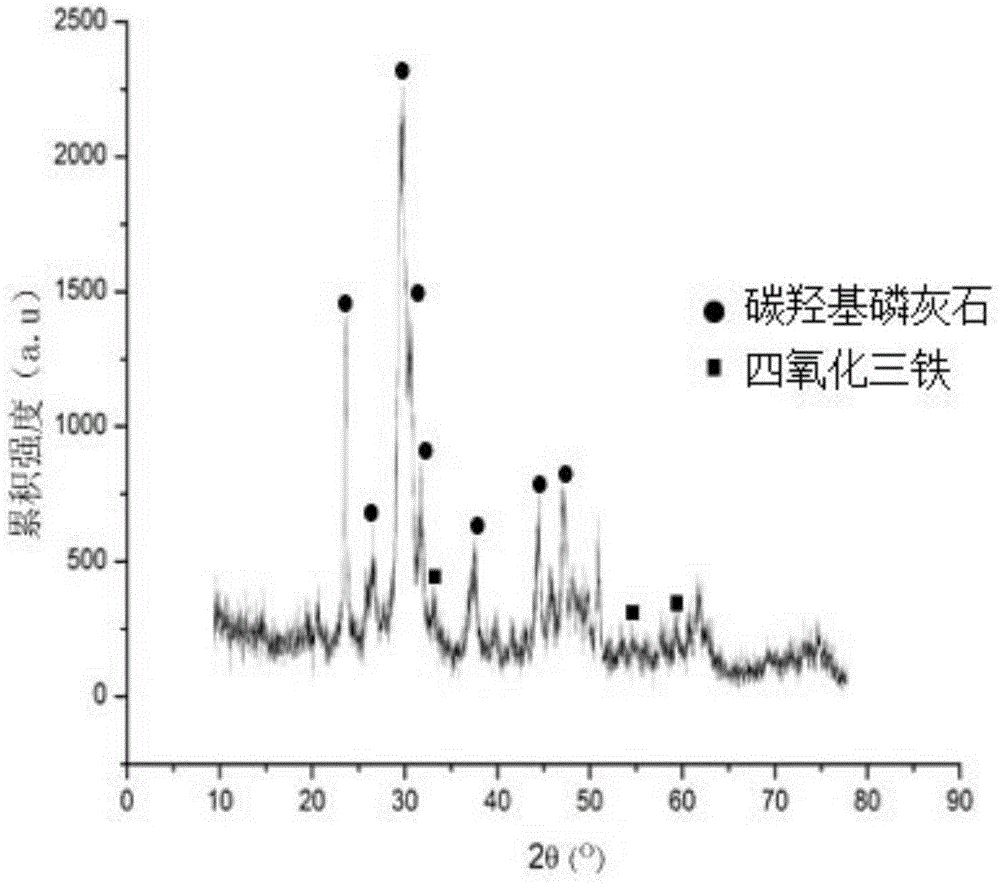

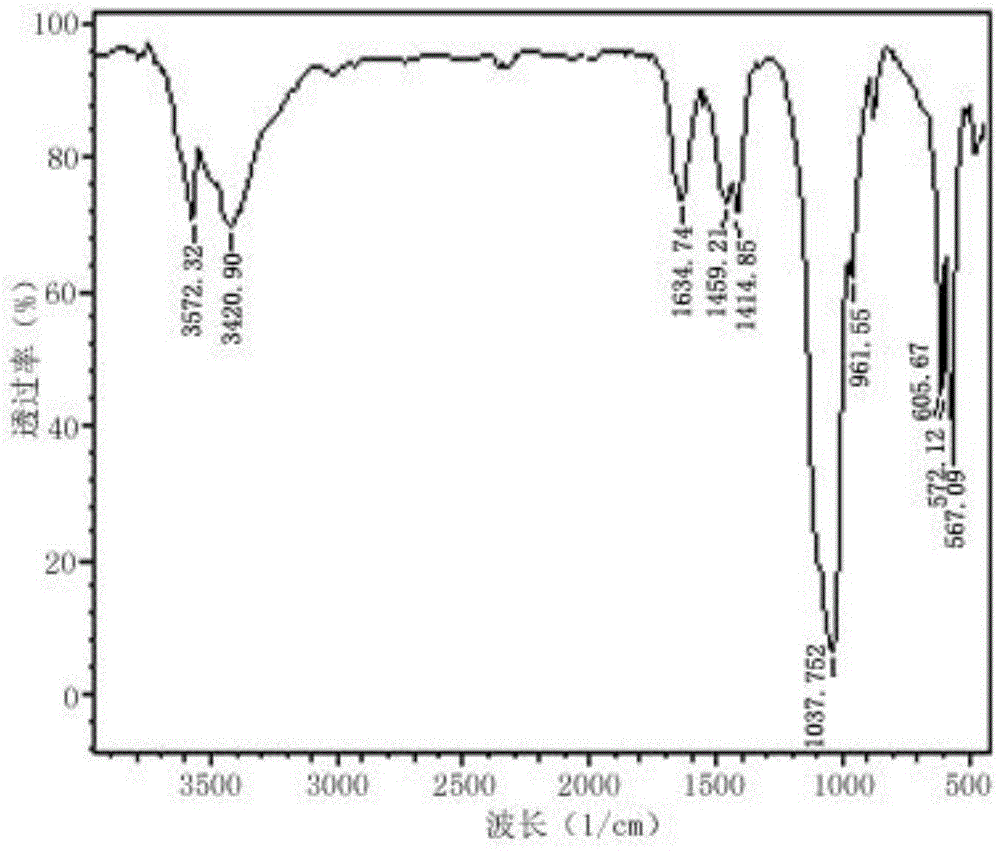

[0033] A magnetic recyclable adsorbent with a specific saturation magnetization of 45-60emu / g and a specific surface area of 250-350g / m 2 , and the ratio of carbonate to phosphate is 1:3.

[0034] A preparation method of a magnetic recyclable adsorbent, the specific preparation steps are:

[0035] (a) Preparation of Hydroxyiron Sol

[0036] The aqueous solution of ferric chloride and ferrous chloride is added to the ethylenediamine solution, the pH of the system is controlled by ethylenediamine to be 8.5-9.0, and then reacted at 60-80°C for 45-60 minutes to prepare the hydroxyl iron sol;

[0037] The molar ratio of described ferric chloride and ferrous chloride is 2: 1;

[0038] The molar concentration of the ferric chloride aqueous solution is 0.1mol / L;

[0039] (b) Preparation of highly carbonate-doped hydroxyapatite-coated hydroxyiron

[0040] After washing the discarded eggshells three times, put them into a solution of formic acid with a mass fraction of 5% and heat...

Embodiment 2

[0052]A magnetic recyclable adsorbent with a specific saturation magnetization of 45-60emu / g and a specific surface area of 250-350g / m 2 , and the ratio of carbonate to phosphate is 1:4.

[0053] A preparation method of a magnetic recyclable adsorbent, the specific preparation steps are:

[0054] (a) Preparation of Hydroxyiron Sol

[0055] The aqueous solution of ferric chloride and ferrous chloride is added to the ethylenediamine solution, the pH of the system is controlled by ethylenediamine to be 8.5-9.0, and then reacted at 60-80°C for 45-60 minutes to prepare the hydroxyl iron sol;

[0056] The molar ratio of described ferric chloride and ferrous chloride is 2: 1;

[0057] The molar concentration of the ferric chloride aqueous solution is 0.3mol / L;

[0058] (b) Preparation of highly carbonate-doped hydroxyapatite-coated hydroxyiron

[0059] After cleaning the discarded eggshells three times, put them in a solution of formic acid with a mass fraction of 8% and heat t...

Embodiment 3

[0069] A magnetic recyclable adsorbent with a specific saturation magnetization of 45-60emu / g and a specific surface area of 250-350g / m 2 , and the ratio of carbonate to phosphate is 1:5.

[0070] A preparation method of a magnetic recyclable adsorbent, the specific preparation steps are:

[0071] (a) Preparation of Hydroxyiron Sol

[0072] The aqueous solution of ferric chloride and ferrous chloride is added to the ethylenediamine solution, the pH of the system is controlled by ethylenediamine to be 8.5-9.0, and then reacted at 60-80°C for 45-60 minutes to prepare the hydroxyl iron sol;

[0073] The molar ratio of described ferric chloride and ferrous chloride is 2: 1;

[0074] The molar concentration of the ferric chloride aqueous solution is 0.5mol / L;

[0075] (b) Preparation of highly carbonate-doped hydroxyapatite-coated hydroxyiron

[0076] After washing the discarded eggshells three times, put them into a formic acid solution with a mass fraction of 5-10% and heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com