Color chain extender, co-polymerized color polyurethane emulsion, color polyurethane-acrylate copolymer emulsion, and preparation method thereof

A technology of polyurethane emulsion and polyurethane prepolymer, applied in the field of color chain extenders, can solve problems such as affecting the mechanical properties of polyurethane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] Specifically, the preparation method of the colored chain extender comprises the following steps:

[0019] S11, dissolving the dye raw material and the hydroxyl functional reagent in a solvent;

[0020] S12, react at 20°C-130°C for 1 hour-8 hours to obtain the colored chain extender.

[0021] In step S11, the molar ratio of the hydroxyl functional reagent to the dye raw material is 1 / 1 to 6 / 1, preferably, the molar ratio of the hydroxyl functional reagent to the dye raw material is 2 / 1 to 3 / 1. The mass ratio of the solvent to the dye raw material is 5 / 1 to 50 / 1, preferably, the mass ratio of the solvent to the dye raw material is 15 / 1 to 25 / 1.

[0022] The dye raw materials are anthraquinone dyes, such as 1-nitroanthraquinone, 1-methylamino-4-bromoanthraquinone, 1-(4-acyl chloride) benzamidoanthraquinone, etc.; azo dyes, Such as 7-benzamido-3-phenylazo-4-(6-chloro)hexyloxy-2-naphthalenesulfonate sodium, 4-methyl-2-(4-benzamido)phenyl Azo-1-(6-chloro)hexyloxybenzene, ...

specific Embodiment

[0057] The present invention will be further described below in conjunction with specific examples, but the specific examples do not limit the present invention in any way.

[0058] The experimental methods described in the following examples are conventional methods unless otherwise specified.

[0059] The raw materials described in the following examples, wherein 1-(4-acyl chloride) benzamidoanthraquinone, 7-benzamido-3-phenylazo-4-(6-chloro)hexyloxy- 2-sodium naphthalenesulfonate, 4-methyl-2-(4-benzamido)phenylazo-1-(6-chloro)hexyloxybenzene, 5-(3-methoxy)propylamino -8-(2-methyl-4-nitro)phenylazo-1-(6-chloro)hexyloxybenzene was synthesized according to the method in Chinese patent (application number: 201310073995.X), and others were obtained from commercial way to get.

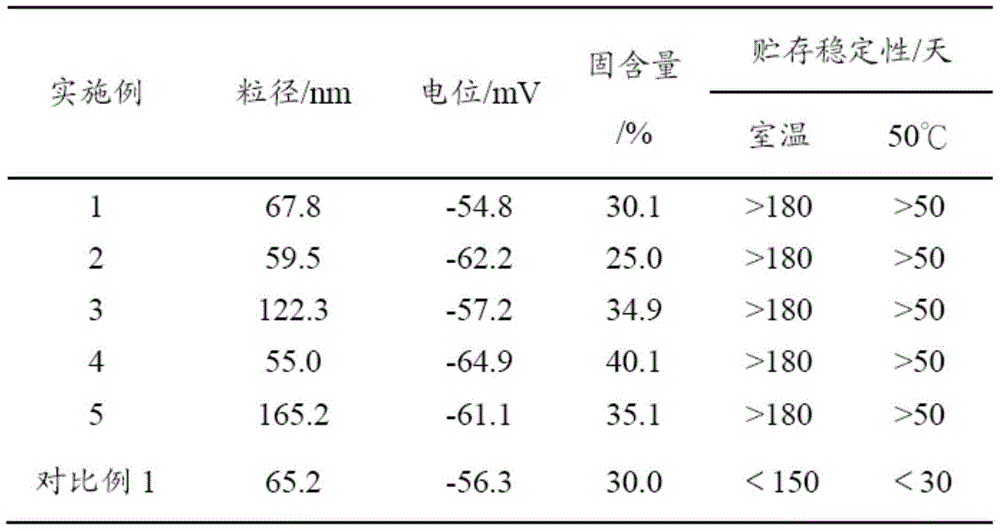

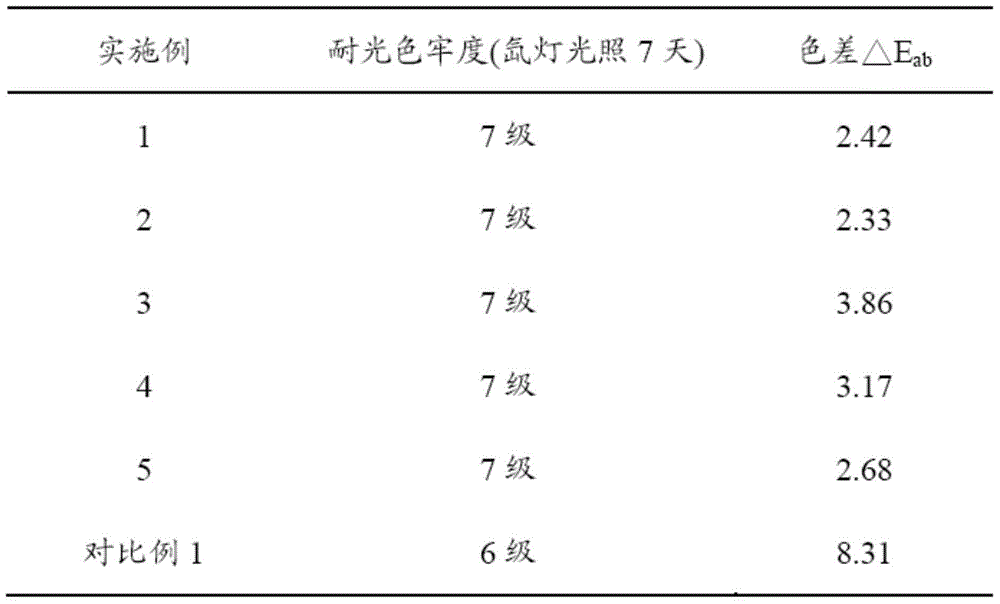

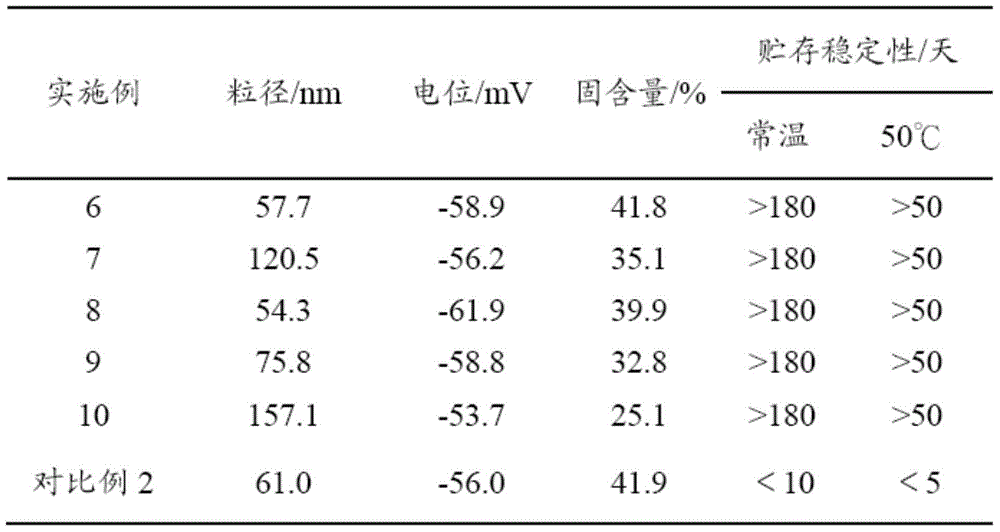

[0060] In all following examples: the solid content of the emulsion is measured by gravimetric method; the latex particle size and potential are measured at 25°C on the Zetasize3000HS laser particle siz...

Embodiment 1

[0062] Embodiment 1—copolymerization type red polyurethane emulsion

[0063] (1) Synthesis of the red chain extender (A): 3.80 grams of 1-nitroanthraquinone, 5.47 grams of 2-amino-1,3-propanediol and 1.59 grams of sodium carbonate were added to a 150 ml single-necked flask, and then 75 milliliter of ethylene glycol dimethyl ether, stirred and heated to 85 ° C for 2.5 hours. After cooling to room temperature, 300 ml of water was added, allowed to stand, filtered, and the filter cake was washed three times with distilled water, then vacuum-dried to obtain a red chain extender (A).

[0064] (2) Preparation of copolymerized red polyurethane emulsion: Add 15 grams of polyether polyol N210, 13 grams of isophorone diisocyanate and 2 drops of dibutyltin dilaurate into a three-necked flask, stir and heat to 80°C and react 2 Hours; then add 1.61 grams of dimethylolpropionic acid, 1.73 grams of 1,6-hexanediol and 0.09 grams of red chain extender (A) for chain extension reaction, react f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com