Preparation method of quantum dot self-assembled film

A technology of self-assembled films and quantum dots, which is applied in measurement devices, manufacturing of microstructure devices, and processes for producing decorative surface effects, etc. Achieving the effect of uniform morphology, simple operation and good film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

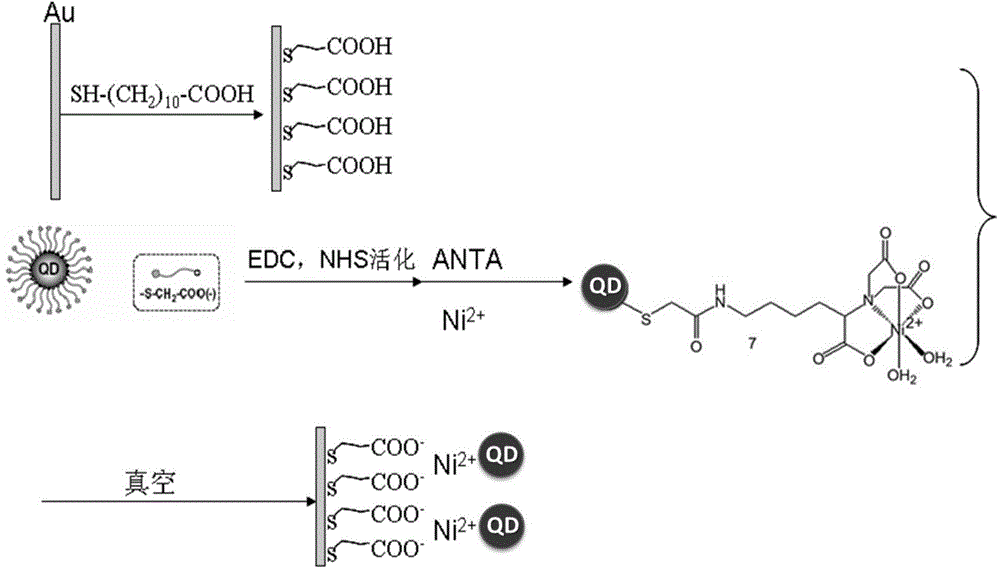

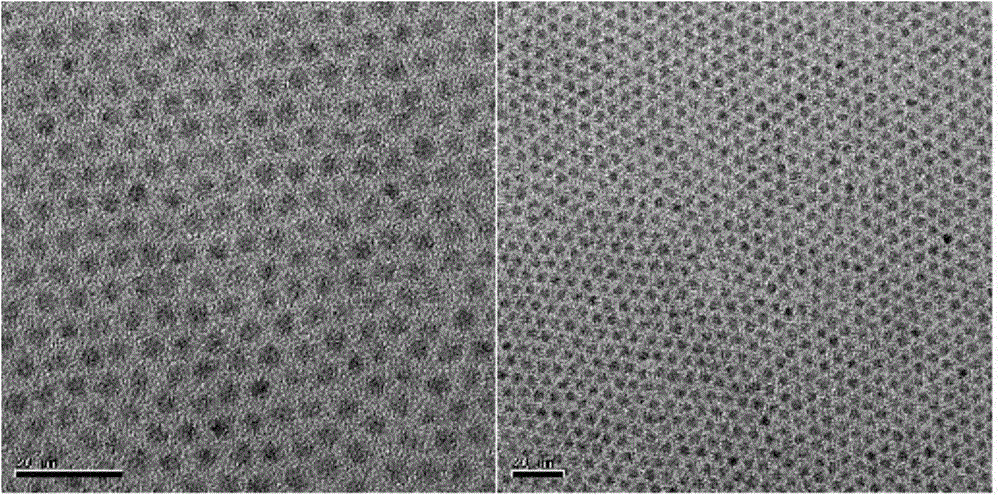

[0058] Example 1 Preparation method of CdSe nanoparticle self-assembled film on the surface of gold-coated glass sheet and application of biological solar cells

[0059] 1. Preparation of oil-soluble CdSe nanoparticles by high temperature oil phase method

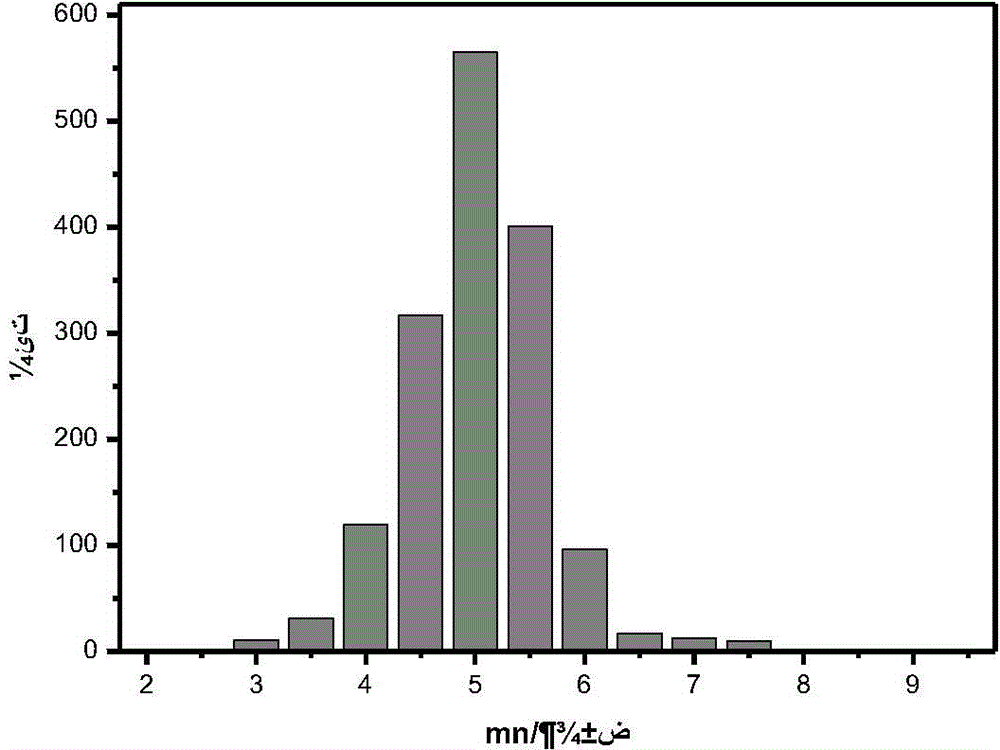

[0060] Mix 2g of trioctylphosphine oxide, 2.8g of dodecylamine, 0.3g of tetradecyl phosphoric acid, and 0.05g of cadmium oxide in a three-necked flask, stir magnetically, vacuumize, protect with inert gas, and heat to 300°C , reacted for 6 hours, added 1 mL of selenium trioctylphosphine solution, reacted for 15 minutes, stopped heating to obtain oil-soluble CdSe nanoparticles with a particle size of 5 nm, and centrifuged to obtain oil-soluble CdSe nanoparticles with a uniform particle size;

[0061] 2. Preparation of water-soluble CdSe nanoparticles by ligand displacement method

[0062] Take the oil-soluble CdSe nanoparticles prepared in step 1, add 4 mL of n-hexane, the concentration of CdSe nanoparticles is 5×10 -3 m...

Embodiment 2

[0071] Example 2 Preparation method of CdTe nanoparticle self-assembled film on the surface of glass sheet with silver-coated gold double metal layer and application of kinetic detection chip based on surface plasmon resonance imaging

[0072] 1. Surface modification of water-soluble CdTe nanoparticles

[0073] After the water-soluble CdTe nanoparticles with carboxy-terminus were prepared from the partner National Center for Nanoscience and Technology, 4 mL of phosphate buffer solution at pH 5.7 was added to obtain a concentration of 2.5 × 10 -3 mol / L water-soluble CdTe nanoparticles, add 1 mL of 0.2 mol / LEDC solution and 0.05 mol / L NHS solution, react for 60 minutes, and centrifuge to obtain water-soluble CdTe nanoparticles with activated carboxyl groups. for 10 -2 mol / L NTA aqueous solution 2mL, react for 2h, add 6×10 -2 mol / LNiSO 4 Alkaline solution 1mL, centrifuged to obtain surface-modified NTA and Ni 2+ CdTe nanoparticles;

[0074] 2. Modification of the surface o...

Embodiment 3

[0081] Example 3 Preparation method of CdSe / ZnS nanoparticle self-assembled film on gold-coated glass surface and application of biomolecular interaction chip based on surface fluorescence enhancement

[0082] 1. Surface modification of water-soluble CdSe / ZnS nanoparticles

[0083] Add water-soluble CdSe / ZnS nanoparticles with carboxyl terminals (purchased from the National Nanoscience Center) to 2 mL of phosphate buffer solution with a pH of 5.7 to obtain a concentration of 5 × 10 -3 mol / L water-soluble CdSe / ZnS nanoparticles, adding concentration of 0.2mol / LEDC solution and concentration of 0.05mol / LNHS solution 1mL, reacted for 60min, centrifuged to obtain activated carboxyl water-soluble CdSe / ZnS nanoparticles, the Nanoparticles were added at a concentration of 10 -2 mol / L NTA aqueous solution 4mL, react for 3h, add 1×10 -2 mol / LNi 2 Cl alkaline solution 1mL, centrifuged to obtain surface-modified NTA and Ni 2+CdSe / ZnS nanoparticles;

[0084] 2. Modification of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com