Method for treating heavy metal wastewater

A technology for heavy metals and wastewater, applied in biological treatment devices, chemical instruments and methods, biological water/sewage treatment, etc., to achieve the effects of improving water-soluble swelling, increasing tolerance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

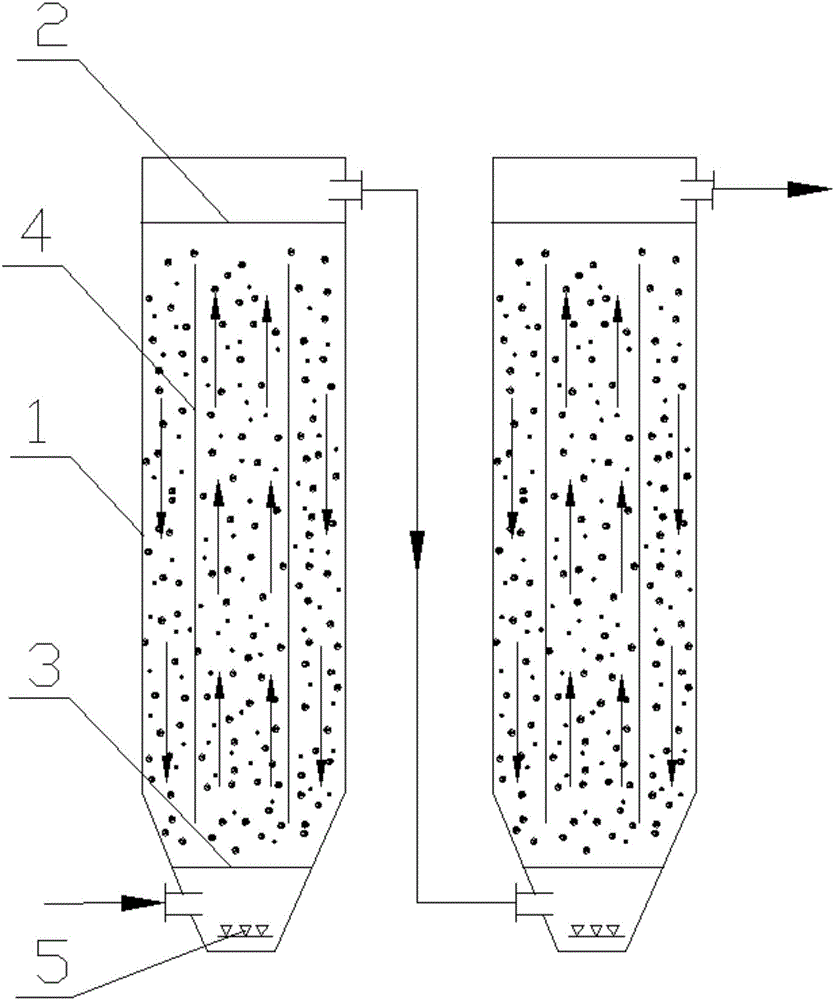

Image

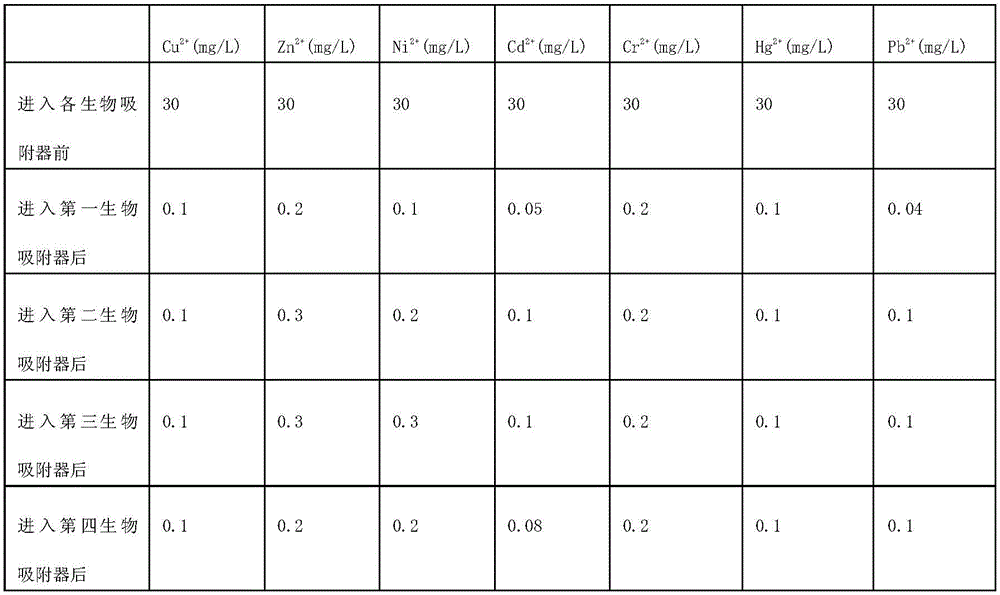

Examples

Embodiment 1

[0027] The mixed fermentation culture process of embodiment 1 class Pseudomonas alcaligenes and Saccharomyces cerevisiae comprises the following steps:

[0028] 1) Cultivation of Saccharomyces cerevisiae seed solution

[0029] Saccharomyces cerevisiae slant strains were inoculated on the first-level seed medium for shake flask culture. After culturing for 24 hours at 27-30°C with a rotation speed of 260rmp, they were inoculated in the second-level seed medium for fermentation tank cultivation at 30°C with a rotation speed of 260rmp and aeration Amount of 2.5 ~ 3m 3 After 24 hours of cultivation per hour, the seed liquid of Saccharomyces cerevisiae was obtained, wherein the primary seed medium was: yeast extract 5g / L, peptone 6g / L, glucose 20g / L; the secondary seed medium was: glucose 40g / L , yeast extract 5g / L, peptone 5g / L, (NH4)2SO42g / L, MgSO4 7H2O0.25g / L, NaCl0.15g / L, KH2PO42.8g / L.

[0030] 2) The cultivation of Pseudomonas alcaligenes seed solution

[0031] Inoculate th...

Embodiment 2

[0034] Embodiment 2 A preparation method of immobilized cell spheres, comprising the following steps:

[0035] A) After mixing polyvinyl alcohol, calcium alginate, acryloyl and water at a mass ratio of 12:1:4:100, polyvinyl alcohol hydrosol is obtained, and the alkali-like pseudomonas collected after mixed fermentation culture Bacteria and Saccharomyces cerevisiae cells were added to polyvinyl alcohol hydrosol to form a mixed solution, wherein the addition amount of Pseudomonas alcaligenes and Saccharomyces cerevisiae cells met the product of adding 5g wet weight per 100mL of polyvinyl alcohol hydrosol. Alkaline Pseudomonas and Saccharomyces cerevisiae mixed bacteria; B) Add the mixed solution to the solution containing 4w / v% N'-methylene bisacrylamide and 1.5w / v% CaSO with a peristaltic pump 4 In a saturated boric acid solution, gel balls are formed, placed at -20°C for 5-10 hours, thawed at room temperature, and then cooled at -10°C for 1-2 hours, after thawing at room tempe...

Embodiment 3

[0036] Embodiment 3 A preparation method of immobilized cell spheres, comprising the following steps:

[0037] A) After mixing polyvinyl alcohol, calcium alginate, acryloyl and water at a mass ratio of 6:0.5:3:100, polyvinyl alcohol hydrosol is obtained, and the alkali-like pseudomonas collected after mixed fermentation culture Bacteria and Saccharomyces cerevisiae cells were added to polyvinyl alcohol hydrosol to form a mixed solution, and the addition amount of Pseudomonas alcaligenes and Saccharomyces cerevisiae cells was controlled to meet the production of 4g wet weight per 100mL of polyvinyl alcohol hydrosol. Alkali Pseudomonas and Saccharomyces cerevisiae mixed bacteria; then the mixed solution was added to the solution containing 3w / v% N'-methylene bisacrylamide and 1w / v% CaSO with a peristaltic pump 4 In a saturated boric acid solution, gel balls are formed, placed at -20°C for 5-10 hours, thawed at room temperature, and then cooled at -10°C for 1-2 hours, after thawi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com