A kind of styrene-acrylic emulsion and the scrub-resistant high PVC interior wall latex paint prepared by it

A technology of latex paint and styrene-acrylic emulsion for interior walls, applied in latex paint, coating, etc., can solve many problems and achieve the effects of improving bearing capacity, simple process and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

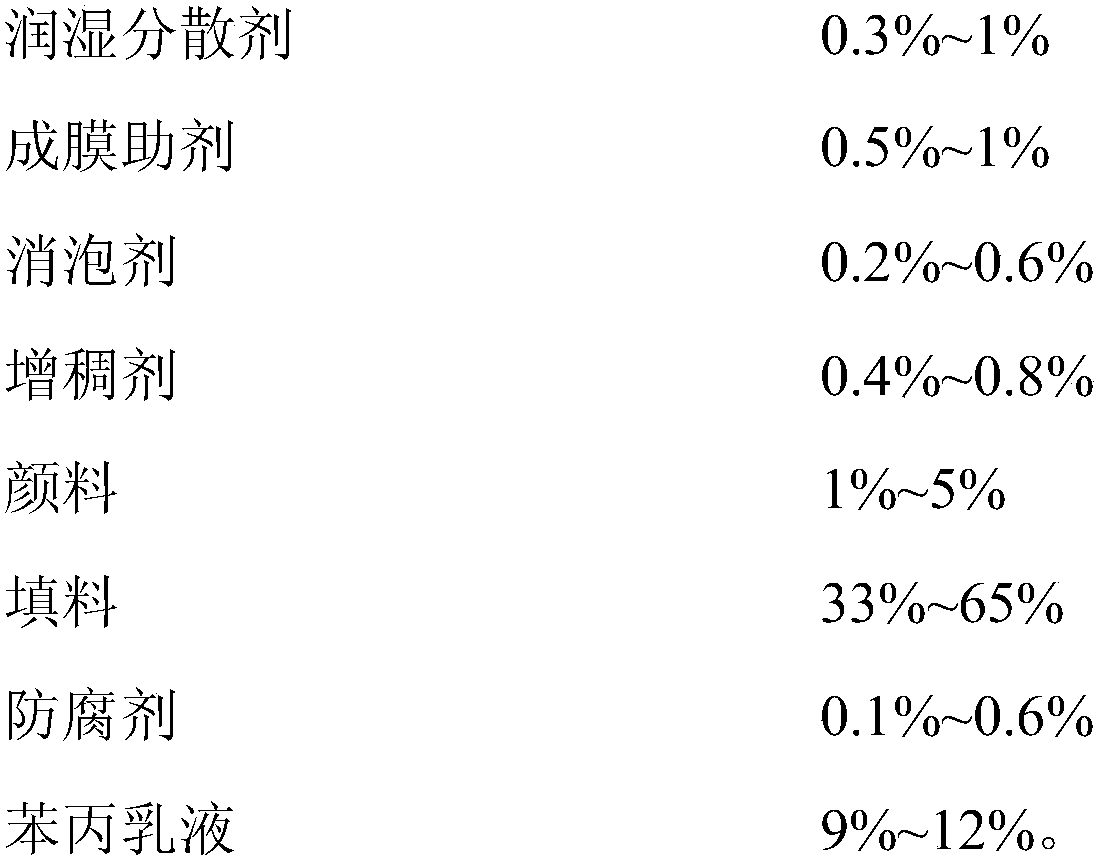

Image

Examples

Embodiment 1

[0050] The styrene-acrylic emulsion (i.e. styrene-acrylate emulsion) is prepared by semi-continuous seed emulsion polymerization, and the used raw material components and weight are as follows:

[0051] Polymerized main monomer: 60g styrene (St), 40g butyl acrylate (BA)

[0052] Other materials: 2g methacrylic acid (MAA), 0.3g functional polymerized monomer 2-acrylamide-2-methylpropanesulfonic acid sodium salt (COPS-2), 0.7g anion-nonionic composite emulsifier isomerization Alcohol polyoxyethylene ether ammonium sulfate (KL-525), 1g crosslinking monomer (SOE-40), 0.5g ammonium persulfate (APS), 0.4g sodium bicarbonate, 100g deionized water;

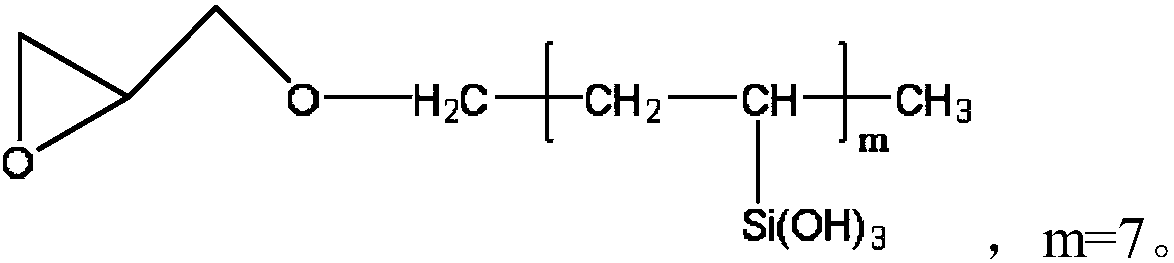

[0053] Wherein, the cross-linking monomer SOE-40 is a product of Foshan Daoning Chemical Co., Ltd., and the specific structural formula of the cross-linking monomer (SOE-40) is:

[0054]

[0055] The preparation method of the self-made styrene-acrylic emulsion for preparing the high PVC interior wall glue coating with excellent scrub ...

Embodiment 2

[0067] The styrene-acrylic emulsion (i.e. styrene-acrylate emulsion) is prepared by semi-continuous seed emulsion polymerization, and the used raw material components and weight are as follows:

[0068] Polymerized main monomer: 60g styrene (St), 40g butyl acrylate (BA)

[0069] Other materials: 2g methacrylic acid (MAA), 0.3g functional polymerized monomer 2-acrylamide-2-methylpropanesulfonic acid sodium salt (COPS-2), 0.7g anion-nonionic composite emulsifier isomerization Alcohol polyoxyethylene ether ammonium sulfate (KL-525), 2g cross-linking monomer (SOE-40), 0.5g ammonium persulfate (APS), 0.4g sodium bicarbonate, 100g deionized water;

[0070] Wherein, the structure of the crosslinking monomer is the same as in Example 1.

[0071] The preparation method of the self-made styrene-acrylic emulsion for preparing the high PVC interior wall glue coating with excellent scrub resistance is as follows:

[0072] (1) Add pH buffer, anionic-nonionic emulsifier (KL-525), initiator...

Embodiment 3

[0083] The styrene-acrylic emulsion (i.e. styrene-acrylate emulsion) is prepared by semi-continuous seed emulsion polymerization, and the used raw material components and weight are as follows:

[0084] Polymerized main monomer: 60g styrene (St), 40g butyl acrylate (BA)

[0085] Other materials: 2g methacrylic acid (MAA), 0.3g functional polymerized monomer 2-acrylamide-2-methylpropanesulfonic acid sodium salt (COPS-2), 0.7g anion-nonionic composite emulsifier isomerization Alcohol polyoxyethylene ether ammonium sulfate (KL-525), 2g cross-linking monomer (link-78), 0.5g ammonium persulfate (APS), 0.4g sodium bicarbonate, 100g deionized water;

[0086] Wherein, the cross-linking monomer link-78 is a product of Foshan Daoning Chemical Co., Ltd., and the specific structural formula of the cross-linking monomer (link-78) is:

[0087]

[0088] The preparation method of the self-made styrene-acrylic emulsion for preparing the high PVC interior wall glue coating with excellent sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com