Preparation method of polysialic acid-hyaluronic acid composite gel, obtained product and application

A technology of polysialic acid and hyaluronic acid, which is applied in the direction of medical preparations of non-active ingredients, liquid delivery, and pharmaceutical formulations, and can solve problems such as reducing user acceptance, lack of a good solution, and increasing user pain , to achieve the effect of easy operation, excellent biocompatibility, and less side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

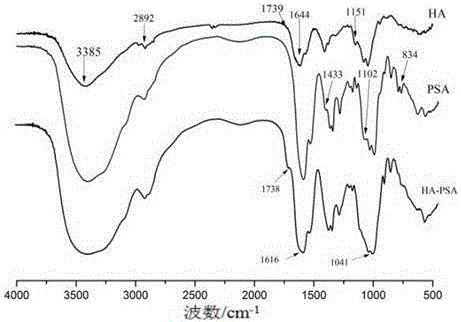

[0057] Take 1.5g PSA (molecular weight 50KDa), dissolve it in 10ml sodium carbonate-sodium bicarbonate buffer solution (pH10), add 0.6ml epichlorohydrin and 1ml sodium hydroxide solution (0.5% mass volume concentration), then stir at 35°C React for 4 hours. After the reaction, the excess epichlorohydrin is removed in vacuum, and then the mixture of water: ethanol (volume ratio 1:4) is precipitated. The precipitate obtained is centrifuged and mixed with water: ethanol (volume ratio 1:4). The solution was repeatedly purified to obtain activated PSA.

[0058] With the ratio of PSA:HA mass ratio of 2:1, the activated PSA was added to 20ml of HA solution with a concentration of 1.5% (g / ml) (HA molecular weight was 1500KDa. The HA solution was prepared with pH6.0 phosphate buffer as the solvent), stirred and reacted at 30°C for 56 hours, after the reaction, the reaction solution was concentrated under reduced pressure to 1 / 4 of the original volume, and the concentrated solution was ...

Embodiment 2

[0061] Take 1.5g polysialic acid (molecular weight 10kDa) and dissolve it in 10ml sodium carbonate-sodium bicarbonate buffer solution (pH8.5~11), then add 0.8ml epichlorohydrin and 2ml sodium hydroxide solution (0.2% mass volume concentration ), magnetically stirred at 35°C for 4 hours, then removed excess epichlorohydrin in vacuum, concentrated the solution to 1 / 4 of its original volume under reduced pressure, and precipitated with a mixture of water:ethanol (volume ratio 1:4) , the resulting precipitate was purified by repeated precipitation and purification with ethanol aqueous solution to obtain activated polysialic acid.

[0062] With the ratio of PSA:HA mass ratio of 2:1, the activated PSA was added to 20ml of HA solution with a concentration of 1.5% (g / ml) (HA molecular weight was 1000KDa. The HA solution was prepared with pH6.0 phosphate buffer as the solvent), stirred and reacted at 30°C for 56 hours, after the reaction, the reaction solution was concentrated under re...

Embodiment 3

[0064] Take 0.5g polysialic acid (molecular weight 100kDa) dissolved in 9ml sodium carbonate-sodium bicarbonate buffer (pH10), then add 0.3ml epichlorohydrin and 1ml sodium hydroxide solution (2% mass volume concentration), at 45 Stir magnetically at ℃ for 3 hours, then remove excess epichlorohydrin in vacuum, concentrate the solution to 1 / 3 of the original volume under reduced pressure, and conduct precipitation with a mixture of water: ethanol (volume ratio 1:4), and the obtained precipitate is used The ethanol aqueous solution was repeatedly precipitated and purified to obtain activated polysialic acid.

[0065] With the ratio of PSA:HA mass ratio of 1:1, add activated PSA to 30ml of HA solution with a concentration of 1% (g / ml) (HA molecular weight is 3000KDa. The HA solution is citric acid-lemon at pH 4.0 Sodium acid buffer solution as the solvent), stirred and reacted at 25°C for 96 hours, after the reaction, the reaction solution was concentrated under reduced pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com