Concrete additive for hydraulic engineering

A concrete admixture and water conservancy engineering technology, applied in the field of water conservancy engineering, can solve the problems of non-corrosion resistance, complex formula, and the admixture may not be suitable, and achieve the effect of reducing the water-cement ratio, reducing the penetration rate, and improving the degree of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

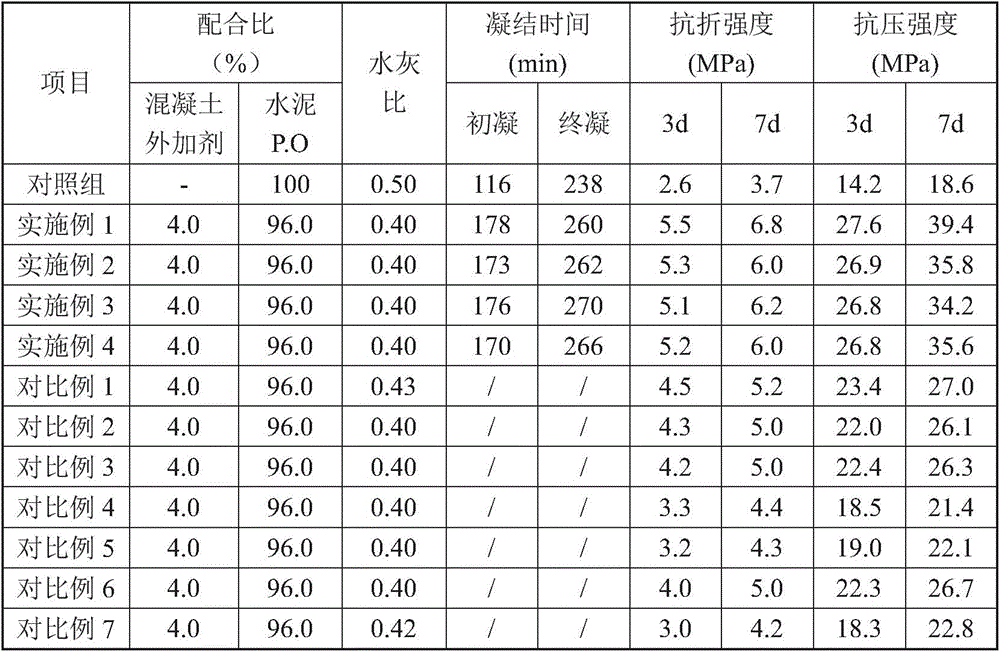

Embodiment 1

[0019] Embodiment 1, concrete admixture for hydraulic engineering of the present invention

[0020] Formula (by weight percentage): 30% of beta-naphthalene sulfonate sodium formaldehyde condensate, 26% fatty alcohol polyoxyethylene ether sulfonate sodium, 8% heavy alkylbenzene sulfonate sodium, 20% polyvinyl alcohol, stearin Acid 12% and Sulfate 4%.

[0021] The polyoxyethylene number of the fatty alcohol polyoxyethylene ether sodium sulfonate is 5, and the carbon number of the alkyl group is 16.

[0022] The sulfate is composed of copper sulfate, calcium sulfate and ammonium sulfate in a weight ratio of 1:2:0.6.

[0023] Preparation method: S1. Weigh polyvinyl alcohol and stearic acid, add water 10 times the weight of polyvinyl alcohol, adjust the pH to 10, start stirring and heating, control the temperature at 75°C, react for 3 hours, then stop heating, add Sulphate, stirred for 30 minutes to obtain a gel-like substance, and the gel-like substance was dried at 90-100°C to ...

Embodiment 2

[0025] Embodiment 2, concrete admixture for hydraulic engineering of the present invention

[0026] Formula (by weight percentage): 26% of β-naphthalene sulfonate sodium formaldehyde condensate, 28% of fatty alcohol polyoxyethylene ether sulfonate, 12% of heavy alkylbenzene sulfonate, 18% of polyvinyl alcohol, stearin Acid 10% and Sulfate 6%.

[0027] The polyoxyethylene number of the fatty alcohol polyoxyethylene ether sodium sulfonate is 5, and the carbon number of the alkyl group is 14.

[0028] The sulfate is composed of copper sulfate, calcium sulfate and ammonium sulfate in a weight ratio of 1:3:0.8.

[0029] Preparation method: S1. Weigh polyvinyl alcohol and stearic acid, add water 12 times the weight of polyvinyl alcohol, adjust the pH to 9, start stirring and heating, control the temperature at 80°C, react for 2 hours, then stop heating, add Sulphate, stirred for 20 minutes to obtain a gel-like substance, which was dried at 90-100°C to obtain a white powder;

[00...

Embodiment 3

[0031] Embodiment 3, concrete admixture for hydraulic engineering of the present invention

[0032] Formula (by weight): 32% of β-naphthalene sulfonate sodium formaldehyde condensate, 22% fatty alcohol polyoxyethylene ether sulfonate sodium, 6% heavy alkylbenzene sulfonate sodium, 22% polyvinyl alcohol, stearin Acid 14% and Sulfate 4%.

[0033] The polyoxyethylene number of the fatty alcohol polyoxyethylene ether sodium sulfonate is 5, and the carbon number of the alkyl group is 18.

[0034] The sulfate is composed of copper sulfate, calcium sulfate and ammonium sulfate in a weight ratio of 1:3:0.4.

[0035] Preparation method: S1. Weigh polyvinyl alcohol and stearic acid, add water 11 times the weight of polyvinyl alcohol, adjust the pH to 10, start stirring and heating, control the temperature at 70°C, react for 3 hours, then stop heating, add Sulphate, stirred for 30 minutes to obtain a gel-like substance, and the gel-like substance was dried at 90-100°C to obtain a white...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com