DNA encoding microsphere and synthetic method thereof

A technology for coding microspheres and synthesis methods, which is applied in the fields of DNA preparation, recombinant DNA technology, DNA/RNA fragments, etc., can solve the problems of high cost and complex synthesis of DNA-coded microspheres, and achieves a small number, simple and reliable design, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

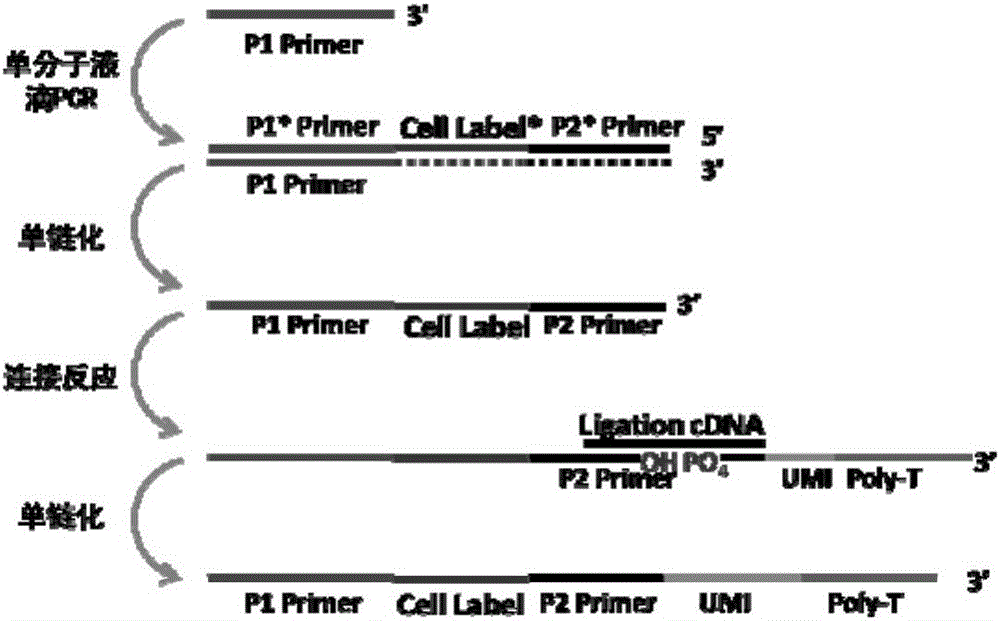

Method used

Image

Examples

Embodiment 1

[0065] Synthesis and purification of embodiment 1 nucleic acid molecule

[0066] Using common controllable microporous glass beads (CPG) as a solid phase carrier and DNA monomer bases as raw materials, the DNA sequences shown in Table 1 were synthesized from the 3' end to the 5' end on a DNA synthesizer. After the synthesis, the above CPG was transferred to a 2 mL clean and sterilized Eppendorf tube, and 0.5 mL of methylamine:ammonia = 1:1 solution was added, and the DNA was cleaved from the CPG by ammonolysis at 65°C for 30 min. After ammonium hydrolysis, extract the supernatant, wash the CPG with a small amount of ultrapure water, and combine the supernatant. Add 2.5 times the volume of frozen absolute ethanol and 0.1 times the volume of 3mol / L NaCl to the system, and carry out alcohol precipitation in a -20°C refrigerator for 30 minutes. After the alcohol precipitation is complete, centrifuge at 14,000rpm for 10min and discard the supernatant. The obtained crude product w...

Embodiment 2 10

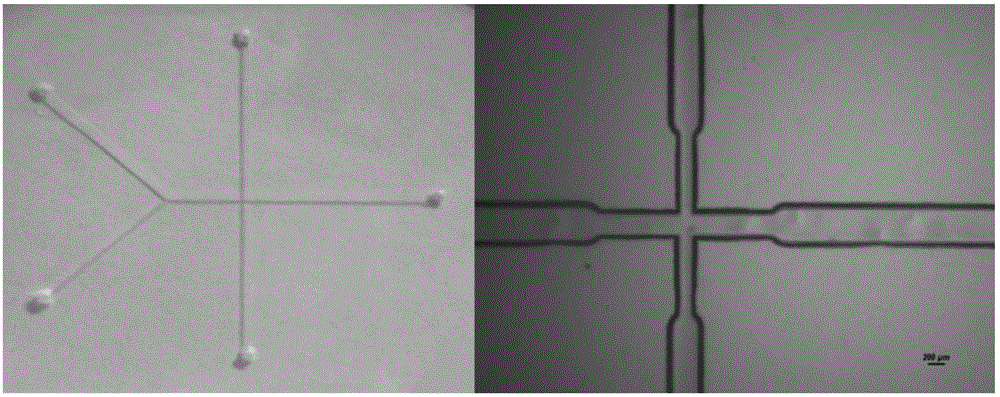

[0067] Example 2 Fabrication of a cross-shaped glass microfluidic chip

[0068] Use AutoCAD software to draw the two-dimensional structure of the chip and make a mask. Use soft lithography technology to transfer the pattern to the chrome plate glass, develop the hard film and remove the chrome layer, then place the chip in the etching solution (HF:HNO 3 :H 2 O=1:2:17) and etch for 100min, the chip structure can be obtained, and the remaining photoresist and chromium layer can be removed. Drill holes with a 1.8mm drill bit. Then put the chip into piranha washing solution (concentrated sulfuric acid / H 2 o 2 , v:v=3:1) to heat for 40min to ensure the cleanliness of the chip. Ultrapure water, acetone, ultrapure water, sulfuric acid, and ultrapure water were used to ultrasonically clean the chip in sequence to ensure the cleanliness of the chip. The etched glass chip and the flat glass of the same material are fixed together with iron clips, and placed in a muffle furnace wit...

Embodiment 3

[0070] The generation of embodiment 3 polyacrylamide microspheres

[0071] Prepare the oil phase and dispersed phase in advance, wherein the proportioning of each component in the oil phase is: 40% (w / w) Dow Corning 5225C, 30% (w / w) Dow Corning 749, 30% (w / w) silicone oil Ar20, The dispersed phase is 20% (w / v) acrylamide, 0.1% N,N'-methylene acrylamide, 0.14% (w / v) ammonium persulfate, and 16 μM acrydite-modified primer aqueous solution. The process of generating uniformly sized acrylamide droplets on the cross-flow focusing chip prepared in Example 2: the acrylamide solution as the dispersed phase and the mixed silicone oil as the continuous phase in the syringe were respectively transferred from the chip by using the Harvard ultra-high pressure precision syringe pump Horizontal channel and vertical channel injection on both sides. The flow rate of the oil phase is 1mL / h, and the flow rate of the water phase is 0.1mL / h. The generated acrylamide droplets are collected into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com