Nano-silicon-carbon compound and preparation method and application thereof

A technology of carbon composite and nano-silicon, which is applied in the comprehensive field of biological waste resources, can solve the problems of low conductivity of Si, insufficient reaction of silicon, and easy aggregation of silicon, etc., and achieves simple and easy preparation methods, wide sources of raw materials, and high specific surface area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) 5g of rice husk is acid boiled to remove inorganic salt ion impurities, and then dried after repeated cleaning;

[0025] (2) Grinding the rice husk boiled with acid in (1) into powder and carbonizing at 600° C. for 6 hours in an inert atmosphere to obtain a black product;

[0026] (3) Mix 2.1 g of the black product in (2) with 1.2 g of aluminum and 10 g of aluminum chloride (AlCl 3 ) and mix evenly, then put the mixture into a tube furnace and heat it to 200°C for 3 hours at a heating rate of 5°C / min, and take it out after the product is cooled to room temperature with the furnace;

[0027] (4) Pickling the product obtained in (3) with hydrochloric acid, washing, filtering, and drying to obtain a nano-silicon-carbon composite product.

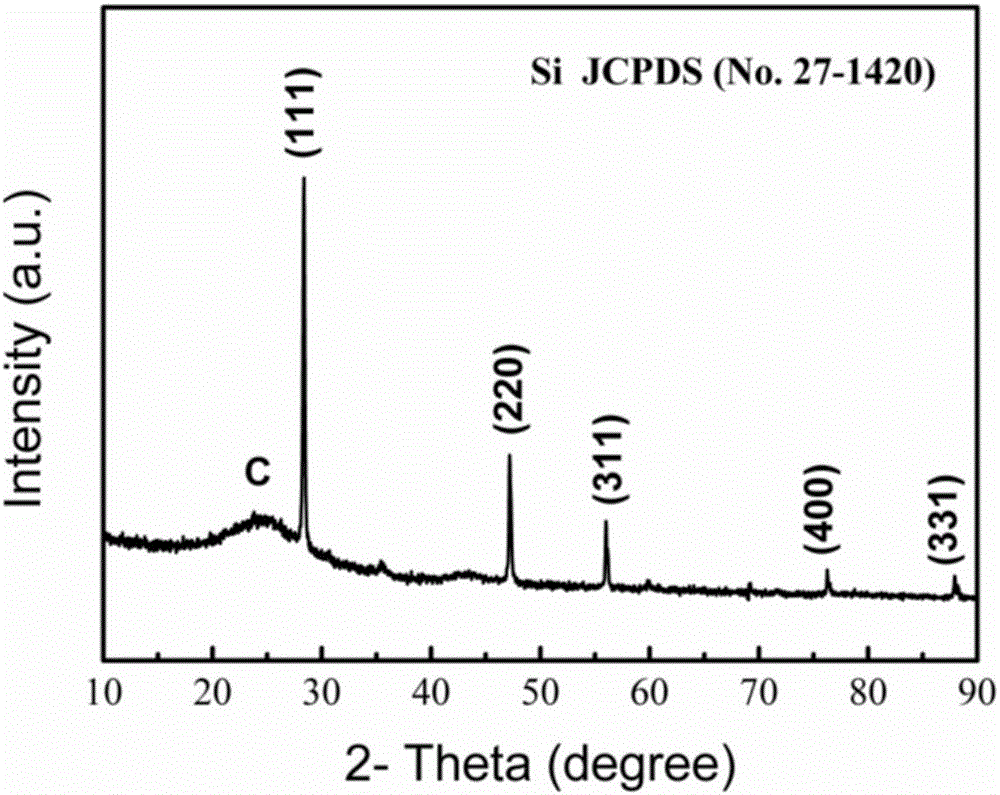

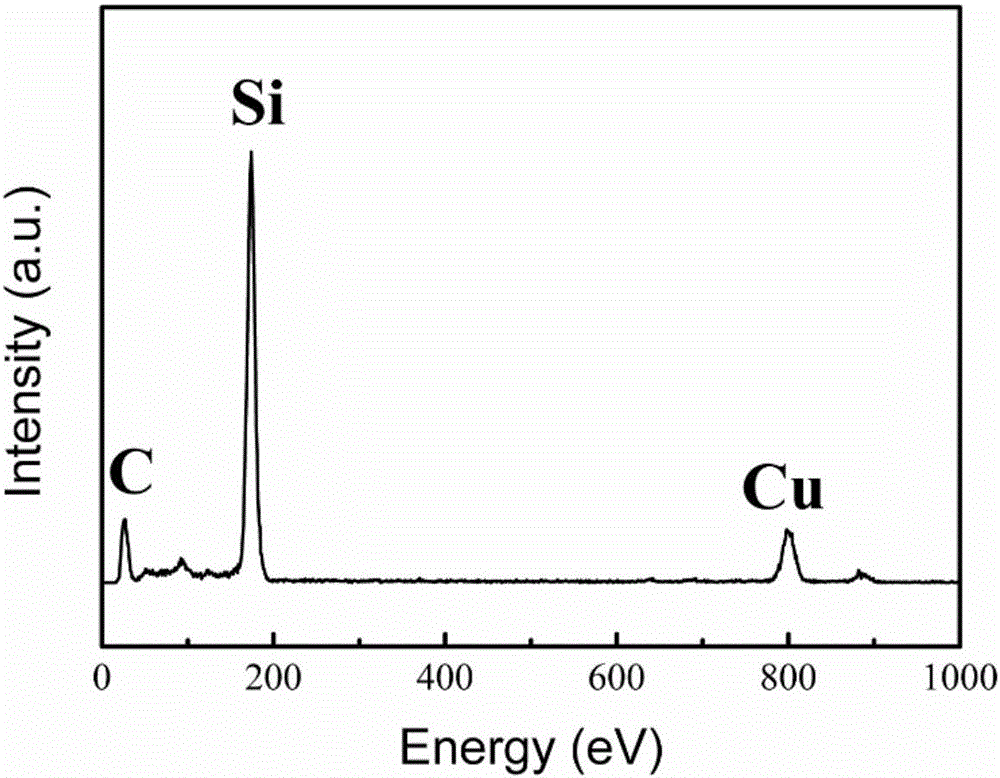

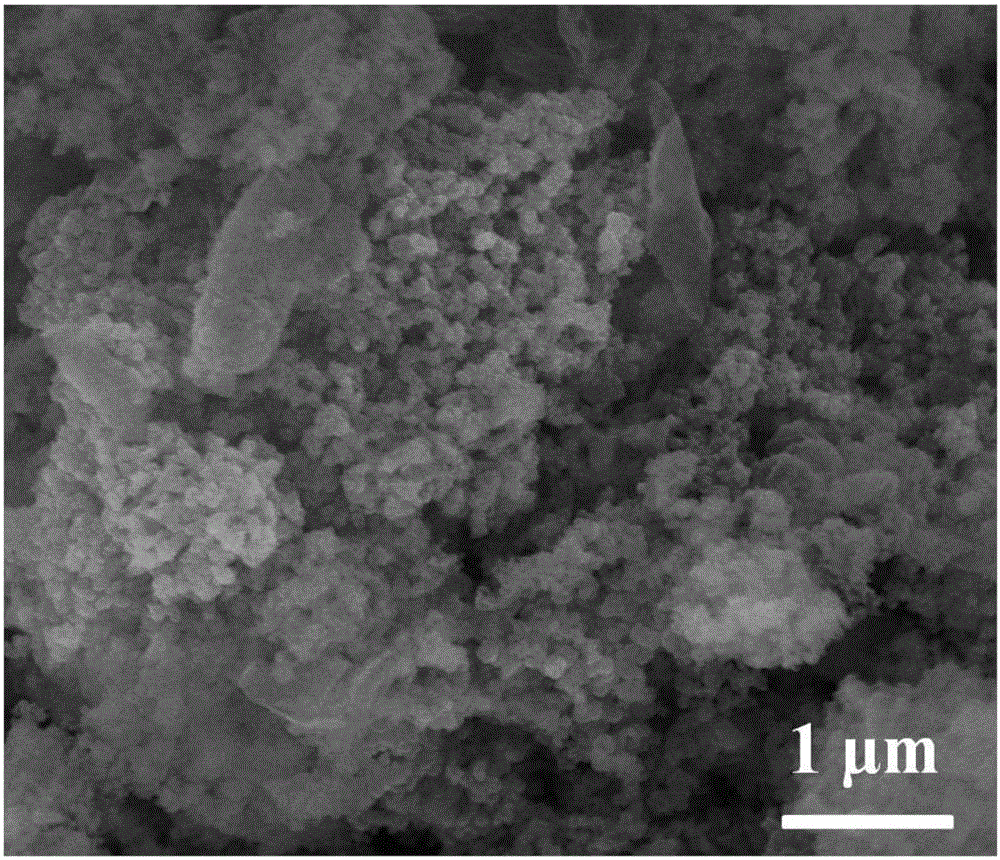

[0028] Depend on figure 1 The XRD diffraction pattern of XRD shows that at 28.4 °, 47.3 ° and 56.1 °, the three strong peaks correspond to the three strong peaks of silicon (JCPDSNo.27-1402), and there is no impurity phase substant...

Embodiment 2

[0030] (1) 5g of bamboo leaf acid is boiled to remove inorganic salt ion impurities, and then dried after repeated cleaning;

[0031] (2) Grinding the bamboo leaves boiled with acid in (1) into powder and carbonizing at 400° C. for 12 hours in an inert atmosphere to obtain a black product;

[0032] (3) Mix 2.8g of the black product in (2) with 2g magnesium and 20g zinc chloride (ZnCl 2 ) and mix evenly, then put the mixture into a tube furnace and heat it to 150°C at a heating rate of 3°C / min for 12 hours, and take it out after the product is cooled to room temperature with the furnace;

[0033] (4) Pickling the product obtained in (3) with hydrochloric acid, washing, filtering, and drying to obtain a nano-silicon-carbon composite product.

Embodiment 3

[0035] (1) 5g of stalks are acid boiled to remove inorganic salt ion impurities, and then dried after repeated washing;

[0036] (2) Grinding the acid-cooked straw in (1) into powder and carbonizing it at 500° C. for 9 hours in an inert atmosphere to obtain a black product;

[0037] (3) Mix 1.5g of the black product in (2) with 1.9g iron and 15g aluminum chloride (AlCl 3 ) and mix evenly, then put the mixture into a tube furnace and heat it to 250°C at a heating rate of 10°C / min for 6 hours, and take it out after the product is cooled to room temperature with the furnace;

[0038] (4) Pickling the product obtained in (3) with hydrochloric acid, washing, filtering, and drying to obtain a nano-silicon-carbon composite product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com