Bismuth oxyiodide / nitrogen doped graphene composite photocatalyst and preparation method thereof

A graphene composite, bismuth iodide technology, applied in the field of photocatalysis, can solve problems such as the composite rate limiting photocatalytic performance, and achieve the effects of excellent electron transport performance, large specific surface area, and improved photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

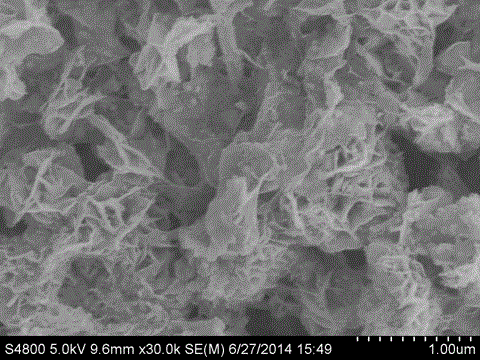

[0043] The first step: 1) Graphene oxide was prepared by the Hume method using graphite powder as raw material, and after repeated suction filtration and washing with deionized water and ethanol, a graphene oxide suspension (2mg / mL) was obtained with deionized water as solvent ;2) Mix 50mL of graphene oxide suspension with 1g of urea (that is, the mass ratio of graphene oxide to urea is 0.1:1) and stir for more than 12 hours, then dry and grind to obtain a mixed solid powder of graphene oxide and urea;3 ) annealing the mixed solid powder above at 1100° C. in a vacuum environment less than 1 Pa to obtain N-doped graphene.

[0044] The second step: 1) Dissolve 1.66g (10mM) potassium iodide in 30mL of ethylene glycol, add 30mg of N-doped graphene obtained in the first step, and ultrasonically disperse for 2 hours to obtain liquid A. 4.85g (10mM) bismuth nitrate pentahydrate (the amount of potassium iodide and other substances, and the mass ratio of N-doped graphene to bismuth nit...

Embodiment 2

[0047] The first step: 1) Graphene oxide was prepared by the Hume method using graphite powder as raw material. After repeated suction filtration and washing with deionized water and ethanol, graphene oxide suspension (1mg / mL) was obtained with deionized water as solvent. ); 2) Mix 100mL of graphene oxide suspension with 1g of urea (that is, the mass ratio of graphene oxide to urea is 0.1:1) and stir for more than 12 hours, then dry and grind to obtain a mixed solid powder of graphene oxide and urea ; 3) annealing the above mixed solid powder at 1100° C. in a vacuum environment less than 1 Pa to obtain N-doped graphene.

[0048] The second step: 1) Dissolve 0.83g (5mM) potassium iodide in 30mL of ethylene glycol, add 30mg of N-doped graphene obtained in the first step, and ultrasonically disperse for 2 hours to obtain liquid A. Dissolve 2.42g (5mM) bismuth nitrate pentahydrate in 30mL ethylene glycol to obtain liquid B, in which the mass ratio of N-doped graphene to bismuth ni...

Embodiment 3

[0051] The first step: 1) Graphene oxide is prepared by the Hume method using graphite powder as raw material. After repeated suction filtration and washing with deionized water and ethanol, graphene oxide suspension (2mg / mL) is obtained with deionized water as solvent ); 2) Mix 50mL of graphene oxide suspension with 1g of urea (that is, the mass ratio of graphene oxide to urea is 0.1:1) and mix and stir for more than 12 hours, then dry and grind to obtain a mixed solid powder of graphene oxide and urea ; 3) annealing the above mixed solid powder at 1100° C. in a vacuum environment less than 1 Pa to obtain N-doped graphene.

[0052] The second step: 1) Dissolve 0.42g (2.5mM) potassium iodide in 30mL of ethylene glycol, add 50mg of N-doped graphene obtained in the first step, and ultrasonically disperse for 2 hours to obtain liquid A. Dissolve 1.21g (2.5mM) bismuth nitrate pentahydrate in 30mL ethylene glycol to obtain liquid B, in which the mass ratio of N-doped graphene to bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com