Compound mouldproof additive for alfalfa hay

A technology of alfalfa hay and additives, which is applied in application, animal feed, animal husbandry, etc. It can solve the problems of compounding natural substances and chemical components that have not been reported, so as to enhance the immunity of livestock, reduce the activity of mold, and strengthen the animal body. The effect of immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Preliminary Screening of Distribution Ratio of Each Group

[0029] According to the synergy and interaction between raw materials, all the ratios (a total of 16 ratio combinations) with good antibacterial and anti-mold effects are designed in theory. Among them, Hay Armer is a kind of alfalfa antifungal agent commonly used in the industry imported from abroad; Eucommia extract is produced by Shaanxi Yuquan Biotechnology Co., Ltd., with a chlorogenic acid content of ≥10%; montmorillonite is Ningcheng County Tianyuan Montmorillonite Development Co., Ltd. Production. Each antifungal agent composition ratio is shown in Table 1 to make 16 kinds of hay antifungal additives, which are stored at room temperature.

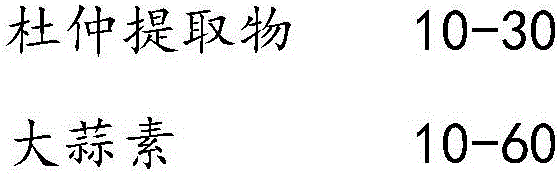

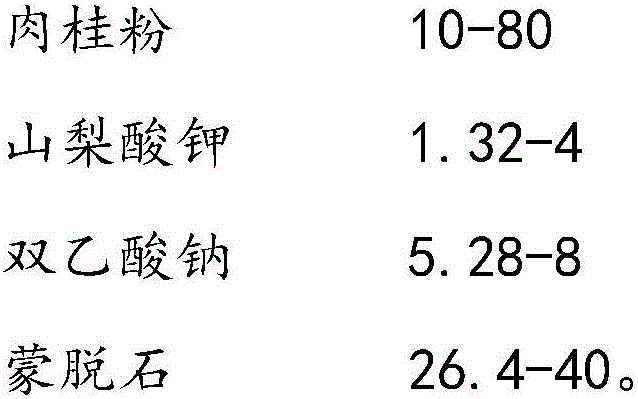

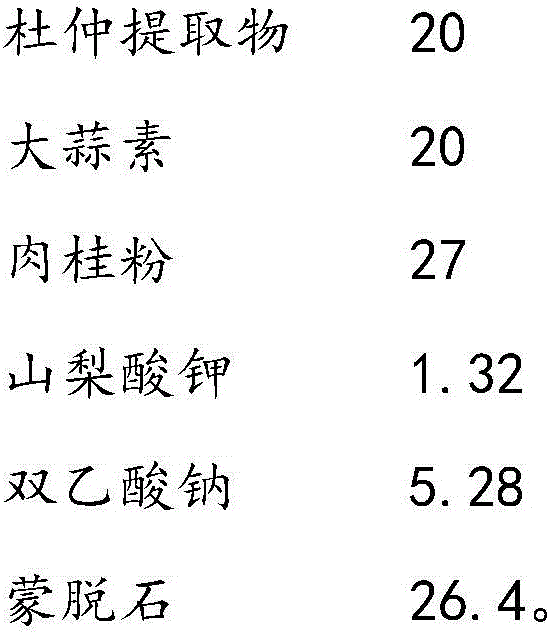

[0030] Table 1. Additive ratio for preliminary screening

[0031]

[0032]

[0033] The 1:10000 dilution multiple mold dilution was prepared by using moldy hay as raw material. The preparation method is as follows: Weigh 25g of alfalfa hay with mo...

Embodiment 2

[0043] Embodiment 2: the high-moisture baling screening of additive ratio

[0044] The better ratio CA1, CA2, and CA3 initially screened out in Example 1 are evenly sprinkled on the alfalfa hay bales with a water content of about 28% according to 0.15%, 0.3%, and 0.45% of the hay quality respectively; Hay Armer (HA ) evenly spread on the alfalfa hay bales according to 0.3% of the hay mass (see Table 4 for the settings of all treatment groups). Afterwards, bales were carried out, and hay bales with a high moisture content of 27-28% moisture content (CKg) and a low moisture content of 17% moisture content (CKd) without additives were set as two controls. Each treatment was repeated 5 times, and each bundle weighed about 20kg, a total of 60 bundles. From the date of baling, the temperature of the bale was measured with a thermocouple at 10:00 every morning until the temperature of all bales became stable. Five bales of hay were measured for each treatment, and each bale of hay w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com