Trough fermentation method of mushroom residue-based organic fertilizer

A trough fermentation and organic fertilizer technology, which is applied in the direction of organic fertilizer, organic fertilizer preparation, bio-organic part treatment, etc., can solve the problem of organic fertilizer decomposing, the degree of organic fertilizer decomposing is not mentioned, production Complicated process and other issues, to achieve the effect of good product quality, shortened fermentation time, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

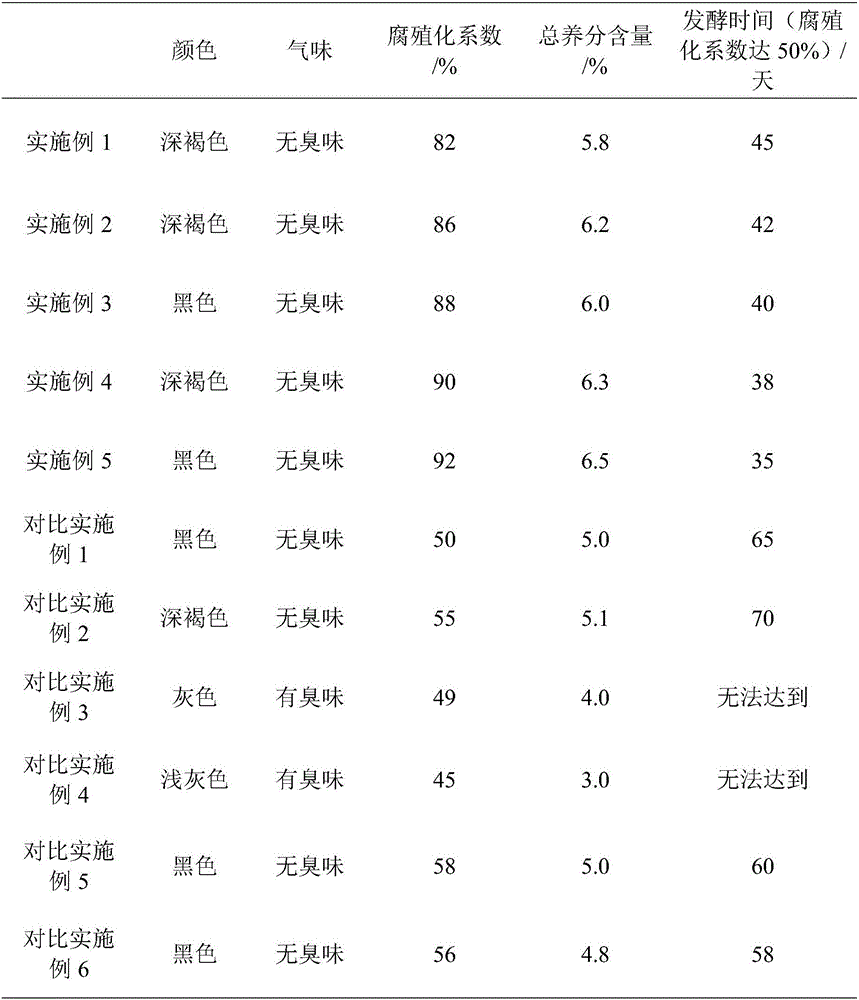

Examples

Embodiment 1

[0028] Carry out tank type fermentation and prepare organic fertilizer according to the following steps:

[0029] (1) Preparation of fermented raw material: by weight, get 50 parts of bacteria residues, 30 parts of pig manure, 20 parts of kitchen waste and mix evenly, add Bacillus subtilis and nitrogen fertilizer, phosphorus fertilizer, potash fertilizer thereinto, adjust the total mixture The C / N ratio is 20, and the total nutrient content is 6.0%;

[0030] (2) tank type fermentation: step (1) gained fermented raw material is carried out into the tank and piled up, and the pile height is set to be 3m, and the water content of fermented raw material is 45%. When the temperature rises to 50°C and lasts for 1 day, use a fertilizer turning machine to turn the fertilizer every 3 days, and the fermentation time is 20 days;

[0031] (3) Stack retting fermentation: after 20 days of trough fermentation, the product of step (2) has no obvious odor, and now it is transferred out from t...

Embodiment 2

[0035] Carry out tank type fermentation and prepare organic fertilizer according to the following steps:

[0036] (1) Preparation of fermented raw material: by weight, get 50 parts of bacteria residues, 30 parts of pig manure, 20 parts of kitchen waste and mix evenly, add Bacillus subtilis and nitrogen fertilizer, phosphorus fertilizer, potash fertilizer thereinto, adjust the total mixture The C / N ratio is 20, and the total nutrient content is 6.0%;

[0037] (2) pre-fermentation: transfer the fermented raw material gained in step (1) to the pre-fermented area for stacking, the height of the heap is set to be 3m, and the water content of the fermented raw material is controlled to be 50%;

[0038] (3) Groove fermentation: when the temperature of the heap at a depth of 30 cm from the top reaches 35°C, transfer the product from step (2) into a fermenter for trough fermentation, set the height of the heap to 3m, and obtain from step (2) The water content of the material is 45%, a...

Embodiment 3

[0043] Carry out tank type fermentation and prepare organic fertilizer according to the following steps:

[0044] (1) Preparation of fermentation raw material: by weight, get 60 parts of bacteria residues, 30 parts of cow dung, 10 parts of kitchen waste and mix evenly, add Bacillus subtilis, Bacillus licheniformis and nitrogen fertilizer, phosphate fertilizer, potassium fertilizer to it, adjust The C / N ratio of the total mixture is 22, and the total nutrient content is 6.3%;

[0045] (2) Tank type fermentation: the fermented material obtained in step (1) is put into the tank and piled up, the height of the heap is set to be 2.5m, and the moisture content of the fermented raw material is 50%. When the body temperature rises to 52°C and continues for 2 days, use a fertilizer turning machine to turn the fertilizer every 4 days, and the fermentation time is 22 days;

[0046] (3) Stack retting fermentation: after 22 days of trough fermentation, the product of step (2) has no obvio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com