Molybdenum carbide/ graphene/carbon nanofiber composite material, and preparation method thereof

A technology of carbon nanofibers and composite materials, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, electrical components, etc., can solve the problems of reducing the exposure of electrochemical active sites, reducing catalytic properties, etc., and achieve easy operation , The preparation process is simple, the effect of good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

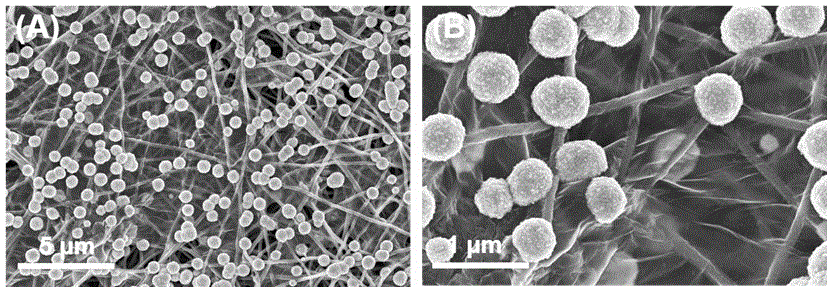

[0038] Embodiment 1, the present embodiment comprises the following steps:

[0039] (1) Add 1 g polyacrylonitrile powder to 10 mL N , N - In the dimethylformamide solvent, keep stirring to prepare a uniform viscous dispersion;

[0040] (2) The obtained polyacrylonitrile dispersion was subjected to electrospinning, and the adjustment process parameters were: electrostatic field voltage 20 kV, spinning speed 0.3 mm min -1 , the receiving distance is 20 cm, and the polyacrylonitrile nanofiber membrane is prepared;

[0041] (3) The obtained polyacrylonitrile spun membrane was pre-oxidized in an air atmosphere, the pre-oxidation temperature was 250 °C, and the heating rate was 1 °C min -1 , the preoxidation time is 1h, and the preoxidized polyacrylonitrile nanofiber membrane is prepared;

[0042] (4) The obtained pre-oxidized polyacrylonitrile nanofiber membrane was mixed with 2 mg mL -1 Soak in graphene oxide solution for 12 h to prepare polyacrylonitrile nanofiber / graphene ox...

Embodiment 2

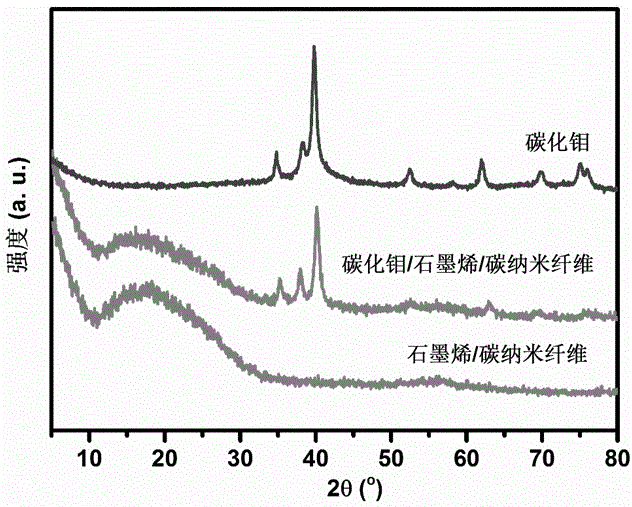

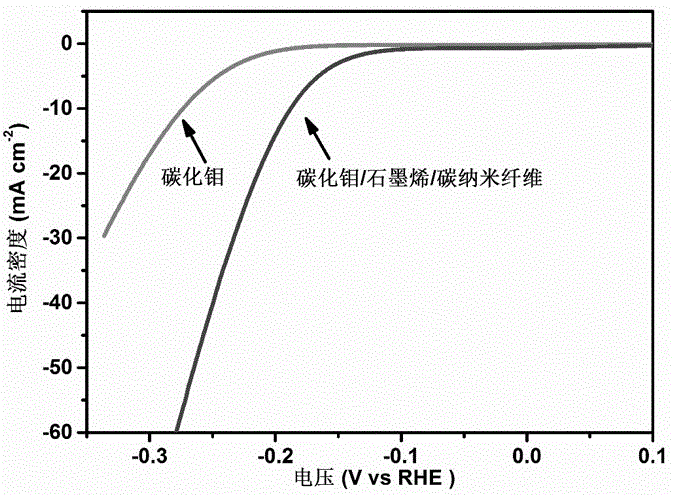

[0048] Example 2. Change the mass of ammonium heptamolybdate in Example 1 to 200 mg, and the mass of glucose to 50 mg, and the rest are the same as in Example 1. The composite material finally obtained is denoted as GCNF@Mo 2 C-2.

Embodiment 3

[0049] Example 3. Change the mass of ammonium heptamolybdate in Example 1 to 400 mg, and the mass of glucose to 100 mg, and the rest are the same as in Example 1. The composite material finally obtained is denoted as GCNF@Mo 2 C-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com