Heat sink material for semiconductors

A heat sink material and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as insufficient bonding between the wrapping layer and the substrate, poor mechanical properties, poor insulation, and affecting thermal conductivity. , to achieve the effect of good mechanical properties, excellent insulation and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The preparation method of the semiconductor heat sink material comprises the following steps:

[0071] S1: the preparation of the matrix, including the following steps:

[0072] S11: Dissolving sodium carbonate and zirconium dioxide sol in water 6-8 times the total mass fraction, then putting in cellulose, soaking for 6-7 hours, and drying at 68-72°C until the water content is ≤8%. To obtain mixture I, mix and grind mixture I and dimethyl itaconate for 3-6 hours to obtain mixture II;

[0073] S12: Add graphite, aluminum oxide, aluminum nitride, silicon nitride, carbon nanotubes, silicon dioxide, kaolin, magnesium oxide, light calcium, binder, coupling agent, compatibilizer, antioxidant, Stabilizer, bridging agent, regulator, strengthening agent, coagulant, toughening agent, stabilizer, terminator, 300-500 parts of water, microwave power 100-300W, temperature 650-700°C, speed 100 Stirring at -400r / min for 3-6h, and then drying the resultant to a water content of ≤8%, t...

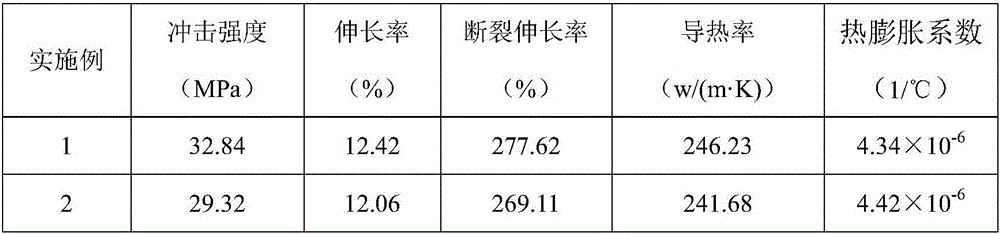

Embodiment 1

[0088] A heat sink material for semiconductors, made of the following raw materials in units of weight: 220 parts of a base, 12 parts of a wrapping layer;

[0089] The matrix is made of the following raw materials in units of weight: 65 parts of graphite, 8 parts of aluminum oxide, 10 parts of aluminum nitride, 12 parts of silicon nitride, 6 parts of carbon nanotubes, 8 parts of silicon dioxide, 3 parts of kaolin, 1.5 parts of magnesium oxide, 2.5 parts of sodium carbonate, 5 parts of zirconia sol, 4 parts of light calcium, 12 parts of cellulose, 4 parts of dimethyl itaconate, 9 parts of binder, coupling agent 1.5 parts, compatibilizer 1.5 parts, antioxidant 1.2 parts, stabilizer 1.2 parts, bridging agent 0.9 parts, regulator 0.7 parts, strengthening agent 0.5 parts, coagulant 0.5 parts, toughening agent 0.3 parts, stabilizer 0.3 parts part, 0.2 part of terminator;

[0090] The coupling agent is an epoxy silane coupling agent;

[0091] Described compatibilizer is maleic an...

Embodiment 2

[0126] A heat sink material for semiconductors, made of the following raw materials in units of weight: 150 parts of a substrate, 8 parts of a wrapping layer;

[0127] The matrix is made of the following raw materials in units of weight: 50 parts of graphite, 6 parts of aluminum oxide, 8 parts of aluminum nitride, 10 parts of silicon nitride, 4 parts of carbon nanotubes, 5 parts of silicon dioxide, 2 parts of kaolin, 1 part of magnesium oxide, 2 parts of sodium carbonate, 4 parts of zirconia sol, 3 parts of light calcium, 9 parts of cellulose, 3 parts of dimethyl itaconate, 5 parts of binder, coupling agent 1 part, compatibilizer 1 part, antioxidant 0.8 part, stabilizer 0.8 part, bridging agent 0.6 part, regulator 0.5 part, strengthening agent 0.4 part, coagulant 0.4 part, toughening agent 0.2 part, stabilizer 0.2 part part, 0.1 part of terminator;

[0128] The coupling agent is an epoxy silane coupling agent;

[0129] Described compatibilizer is maleic anhydride graft com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com