A kind of composite biofiller and preparation method thereof

A technology of biological fillers and pellets, applied in the field of ceramic fillers, can solve the problems of large proportion of inorganic fillers, difficulty in forming fluid state, small specific surface area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

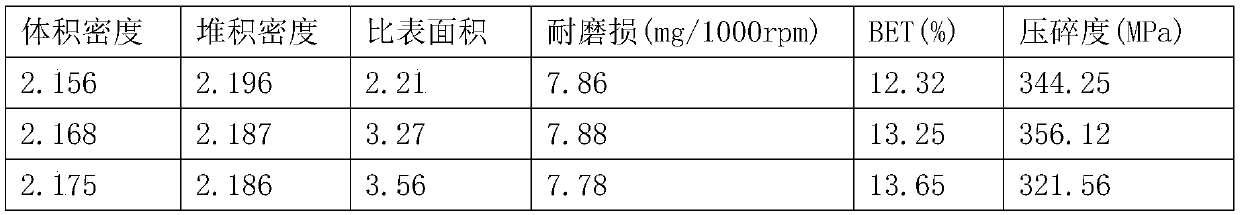

Embodiment 1

[0047] Attapulgite and bituminous coal are both 200 mesh. Mix 60% of attapulgite with 40% of bituminous coal (mass ratio), and prepare pellets with a particle size of 6-8mm by using a disc granulator. Put the sample in a tray to dry naturally for 24 hours, put it in a ceramic crucible, heat it up to 120°C in a constant temperature blast drying oven, take it out after drying for 2 hours, and put it directly in a box-type resistance furnace for sintering for 2 hours, the sintering temperature is 1000 ℃, keep warm for 20min and then cool down to room temperature naturally to make the required filler.

Embodiment 2

[0049] Attapulgite and bituminous coal are both 200 mesh. Mix 70% of attapulgite with 30% of bituminous coal (mass ratio), and prepare pellets with a particle diameter of 6-8mm by using a disc granulator. Put the sample in a tray to dry naturally for 24 hours, put it in a ceramic crucible, heat it up to 120°C in a constant temperature blast drying oven, take it out after drying for 2 hours, and put it directly in a box-type resistance furnace for sintering for 2 hours, the sintering temperature is 1000 ℃, keep warm for 20min and then cool down to room temperature naturally to make the required filler.

Embodiment 3

[0051] Attapulgite and bituminous coal are both 200 mesh. Mix 80% of attapulgite with 20% of bituminous coal (mass ratio), and prepare pellets with a particle size of 6-8mm by using a disc granulator. Put the sample in a tray to dry naturally for 24 hours, put it in a ceramic crucible, heat it up to 120°C in a constant temperature blast drying oven, take it out after drying for 2 hours, and put it directly in a box-type resistance furnace for sintering for 2 hours, the sintering temperature is 1000 ℃, keep warm for 20min and then cool down to room temperature naturally to make the required filler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com