Polymer graphene oxide antirust paint

A graphene and anti-rust paint technology, applied in the field of anti-rust paint, can solve the problems of inability to protect metal machinery and equipment well, reduce the service life of machinery and equipment, unfavorable safety production, etc., achieve superior acid and alkali corrosion resistance, improve Adhesive performance, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

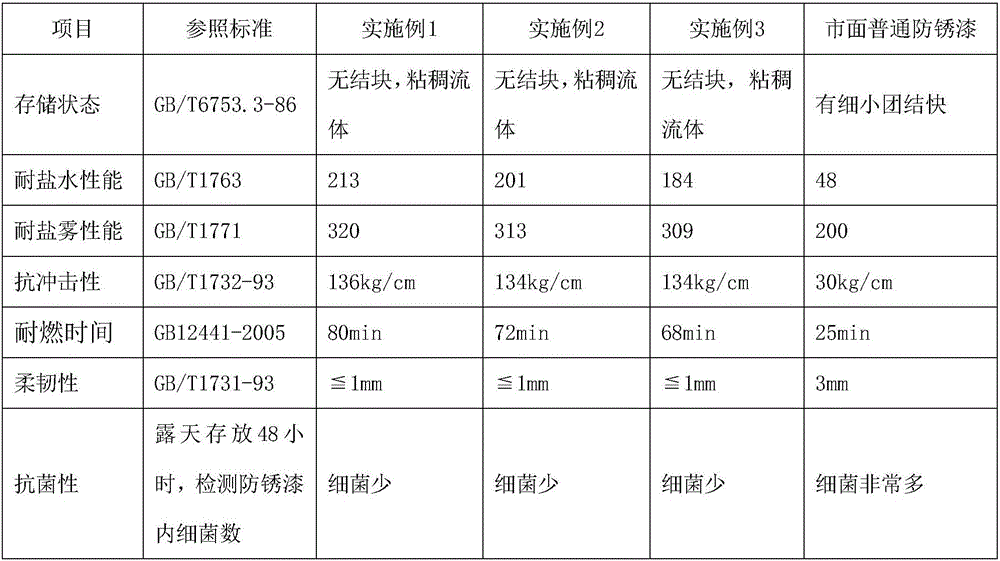

Examples

Embodiment 1

[0013] A polymerized graphene oxide antirust paint, made of the following raw materials in parts by weight: 18 parts of polyvinyl chloride grafted maleic anhydride emulsion, 36 parts of acrylic acid emulsion, 6 parts of succinic acid, 6 parts of epoxy soybean oil, alkyl 3 parts of polyethylene glycol ether, 3 parts of acetyl tris(2-ethylhexyl) citrate, 3 parts of isopropyl myristate, 6 parts of phytic acid ester, 0.8 part of dyclonine hydrochloride, 20- 2.5 parts of 50-mesh medical stone powder, 1.5 parts of sodium fluorosilicate, and 6 parts of polymerized graphene oxide.

[0014] The polymerized graphene oxide is made of the following raw materials in parts by weight: 5 parts of graphene oxide, 1.5 parts of sodium dodecylbenzene sulfonate, 1 part of mercaptobenzothiazole, 0.8 part of jujube tincture, phenyl α-naphthylamine 1.5 parts, 3.5 parts of ethylenediamine tetramethylene phosphonic acid, 0.8 parts of polyadipate-1,4-butylene glycol ester diol; the preparation method is...

Embodiment 2

[0019] A polymerized graphene oxide antirust paint, made of the following raw materials in parts by weight: 10 parts of polyvinyl chloride grafted maleic anhydride emulsion, 32 parts of acrylic acid emulsion, 5 parts of succinic acid, 5 parts of epoxy soybean oil, alkyl 2 parts of polyethylene glycol ether, 2 parts of acetyl tris(2-ethylhexyl) citrate, 2 parts of isopropyl myristate, 5 parts of phytic acid ester, 0.5 part of dyclonine hydrochloride, 20- 2 parts of 50-mesh medical stone powder, 1 part of sodium fluorosilicate, and 4 parts of polymerized graphene oxide.

[0020] The polymerized graphene oxide is made from the following raw materials in parts by weight: 4 parts of graphene oxide, 1 part of sodium dodecylbenzenesulfonate, 0.5 part of mercaptobenzothiazole, 0.5 part of jujube tincture, phenyl α-naphthylamine 1 part, 2.5 parts of ethylenediamine tetramethylene phosphonic acid, 0.5 part of polyadipate-1,4-butylene glycol ester diol; the preparation method is to mix t...

Embodiment 3

[0025] A polymerized graphene oxide antirust paint, made of the following raw materials in parts by weight: 26 parts of polyvinyl chloride grafted maleic anhydride emulsion, 40 parts of acrylic acid emulsion, 8 parts of succinic acid, 8 parts of epoxy soybean oil, alkyl 4 parts of polyethylene glycol ether, 4 parts of acetyl tris(2-ethylhexyl) citrate, 4 parts of isopropyl myristate, 8 parts of phytic acid ester, 1 part of dyclonine hydrochloride, 20- 3 parts of 50-mesh medical stone powder, 2 parts of sodium fluorosilicate, and 8 parts of polymerized graphene oxide.

[0026] The polymerized graphene oxide is made of the following raw materials in parts by weight: 6 parts of graphene oxide, 2 parts of sodium dodecylbenzenesulfonate, 1.5 parts of mercaptobenzothiazole, 1 part of jujube tincture, phenyl α-naphthylamine 2 parts, 4 parts of ethylenediamine tetramethylene phosphonic acid, 1 part of polyadipate-1,4-butylene glycol ester diol; the preparation method is to mix the raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com