Preparation method of magnetic immobilized lipase capable of being used in organic media

A technology for immobilizing lipase and lipase, applied in the directions of biochemical equipment and methods, immobilization on or in inorganic carriers, enzymes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

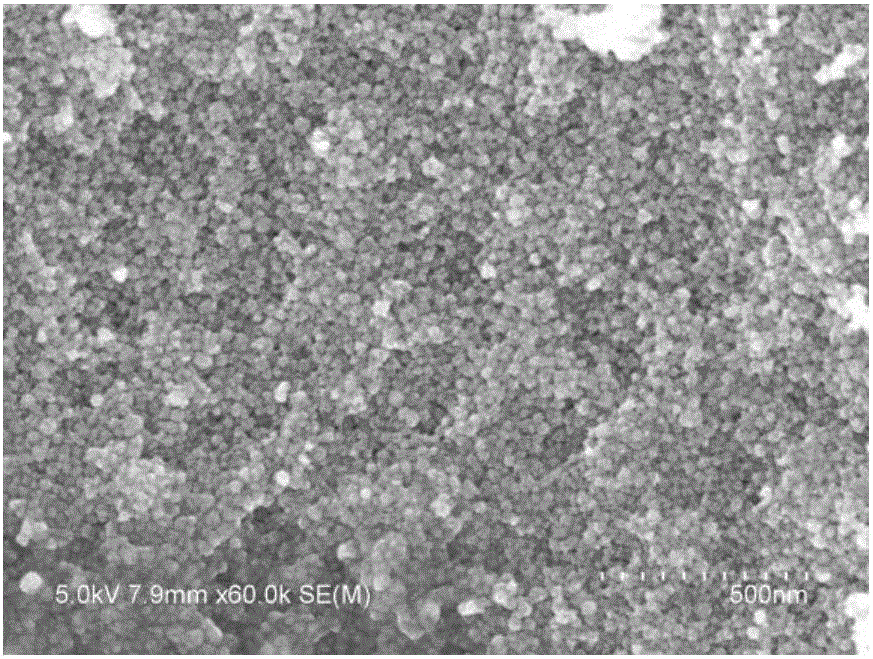

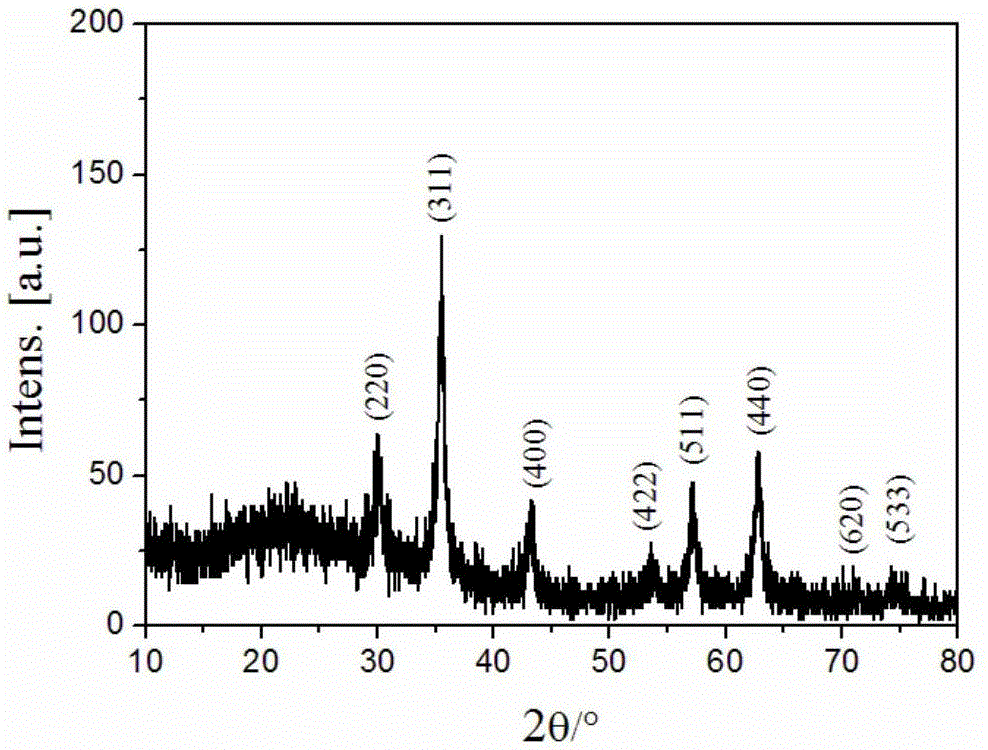

[0050] In the preparation method of magnetically immobilized lipase provided by the invention, the magnetic Fe 3 o 4 / P(St-AA) nanospheres were synthesized by the following method:

[0051] Step 1. Weigh 1059.5 mg of iron acetylacetonate and add it to 20 mL of diphenyl ether, then add 2 mL of oleylamine, 1 mL of ethylene glycol, and 2 mL of oleic acid, stir evenly, and react for 0.5 h at 200 ° C in a nitrogen atmosphere , and then reflux at 250° C. for 2 hours, stop heating, cool to room temperature, magnetically separate the black product, and wash with ethanol three times to obtain ferric oxide nanoparticles coated with oleic acid-oleylamine;

[0052] Step 2. Add 36mL sodium lauryl sulfate solution (mass concentration, 0.1mol / L) in the iron ferric oxide nano-particle of oleic acid-oleylamine wrapping obtained in step 1, after stirring and mixing, then Disperse under ultrasonic conditions for 15 minutes to prepare a magnetic ferric oxide emulsion;

[0053] Step 3. Add 90 m...

Embodiment 2

[0067] Magnetic Fe 3 o 4 The preparation of / P(St-AA) nanospheres is the same as in Example 1.

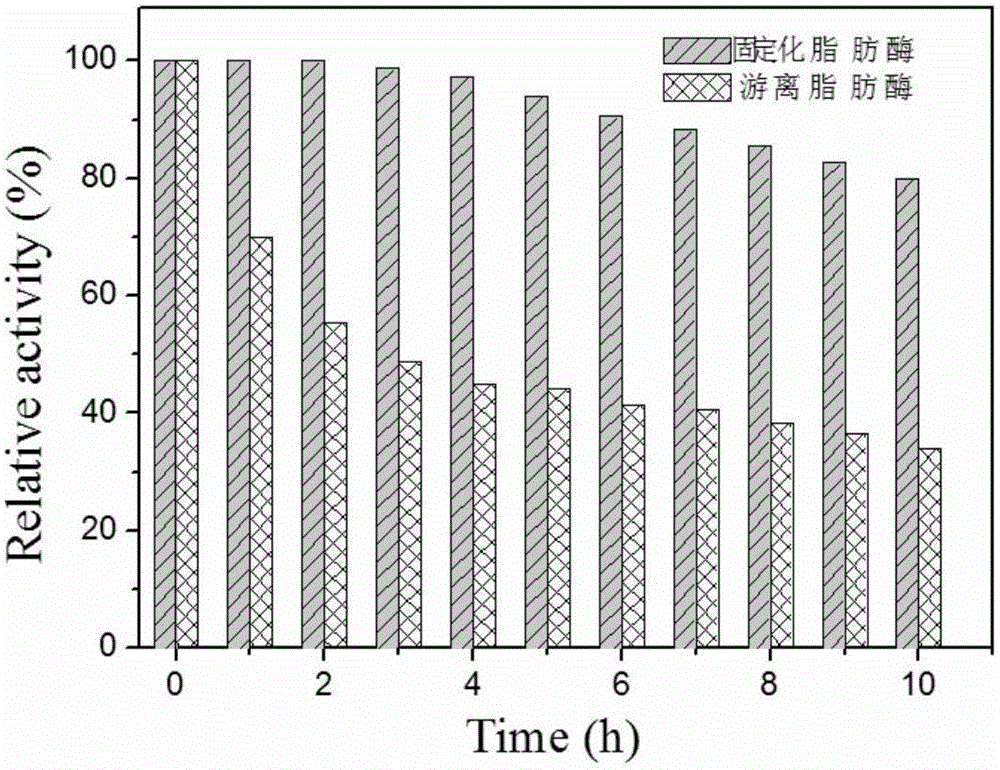

[0068] Magnetic Fe 3 o 4 The operation process of / P(St-AA) nanosphere immobilized lipase is as follows:

[0069] Step 1. The freeze-dried lipase powder derived from porcine pancreas is prepared into a 1 mg / mL lipase solution with pH=7.4 phosphate buffer, and stored in a refrigerator at 4°C for later use;

[0070] Step 2. take by weighing the magnetic Fe that 100mg above-mentioned method makes 3 o 4 / P(St-AA) nanospheres, sequentially added 191.7mg 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride, 57.6mg N-hydroxysuccinimide and 20mL morpholine Ethansulfonic acid buffer solution (0.1mol / L, pH=6.0), ultrasonically dispersed for 2min, and reacted at 25°C for 3h, the obtained product was magnetically separated and washed to obtain activated magnetic polystyrene nanospheres.

[0071] Step 3. Add 40mL of the above-mentioned lipase solution to the above-mentioned activat...

Embodiment 3

[0075] In the preparation method of magnetically immobilized lipase provided by the invention, the magnetic Fe 3 o 4 / PS-CH 2 Cl nanospheres were synthesized by the following method:

[0076] According to step 1 and step 2 of Example 1, a magnetic iron ferric oxide emulsion was prepared; 72 mg of sodium lauryl sulfate and 5 mL of p-chloromethyl styrene were added successively to 24 mL of water, and after stirring and mixing evenly, the Disperse for 20 minutes to prepare a p-chloromethylstyrene monomer emulsion; mix the obtained magnetic iron ferric oxide emulsion and p-chloromethylstyrene monomer emulsion evenly, and add 30mg Potassium persulfate initiator, after reacting at 80°C for 2 hours, then add 30mg of potassium persulfate initiator, and react at 80°C for another 20h, after the reaction is completed, naturally cool to room temperature, and the obtained precipitate is subjected to magnetic separation, Magnetic Fe after washing and drying 3 o 4 / PS-CH 2 Cl nanospher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com