Nickel metaphosphate micro-nanomaterial as well as preparation method and application thereof

A nickel metaphosphate micro-nano material technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of potential application research limitations, unreported, complex reaction systems, etc., to achieve large-scale production and application, significant pseudocapacitive properties, and the effect of simple experimental manipulations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

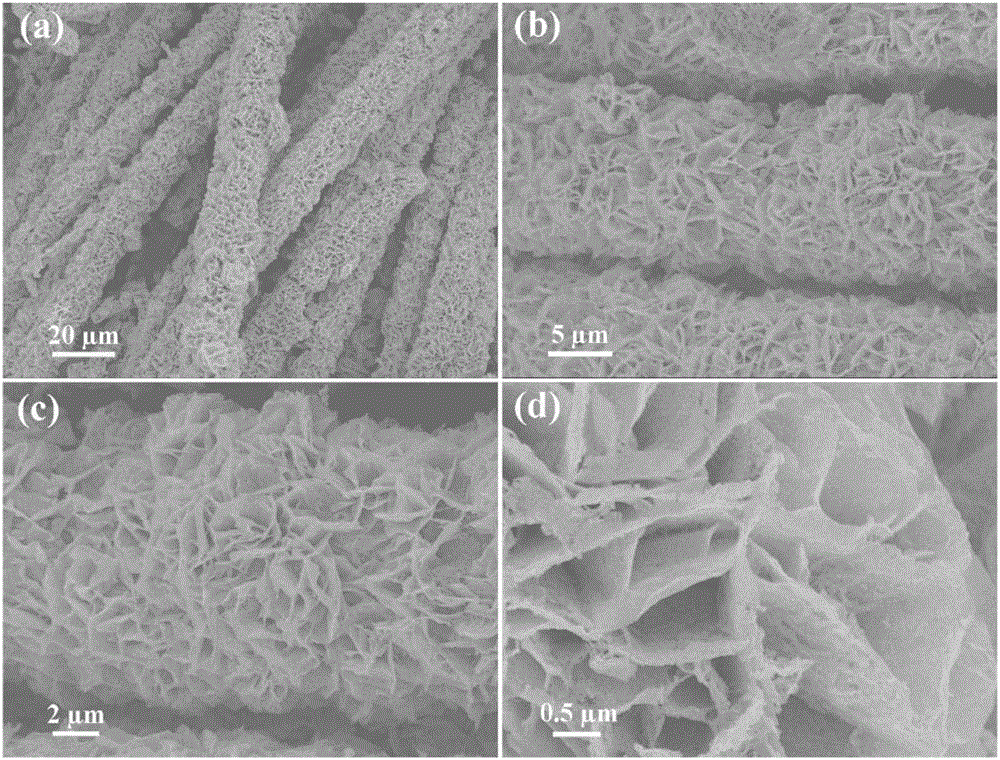

[0043] Stir 1mmol of nickel chloride, 2.5mmol of ammonium fluoride and 5mmol of urea until dissolved in 30mL of deionized water, and then put it into the 2Carbon cloth, let it stand for 2h for use. The carbon cloth was refluxed in concentrated nitric acid for 2 hours in advance, and then it was taken out and washed and vacuum-dried. Then the obtained reaction substrate was transferred to a polytetrafluoroethylene liner, and the polytetrafluoroethylene liner was sealed into a stainless steel mold, heated from room temperature and reacted at 110° C. for 2 h. After the reaction was completed, it was naturally cooled to room temperature, and the carbon cloth was taken out from the polytetrafluoroethylene lining, ultrasonically cleaned with deionized water and ethanol, and dried to obtain a nickel-containing precursor / carbon cloth composite.

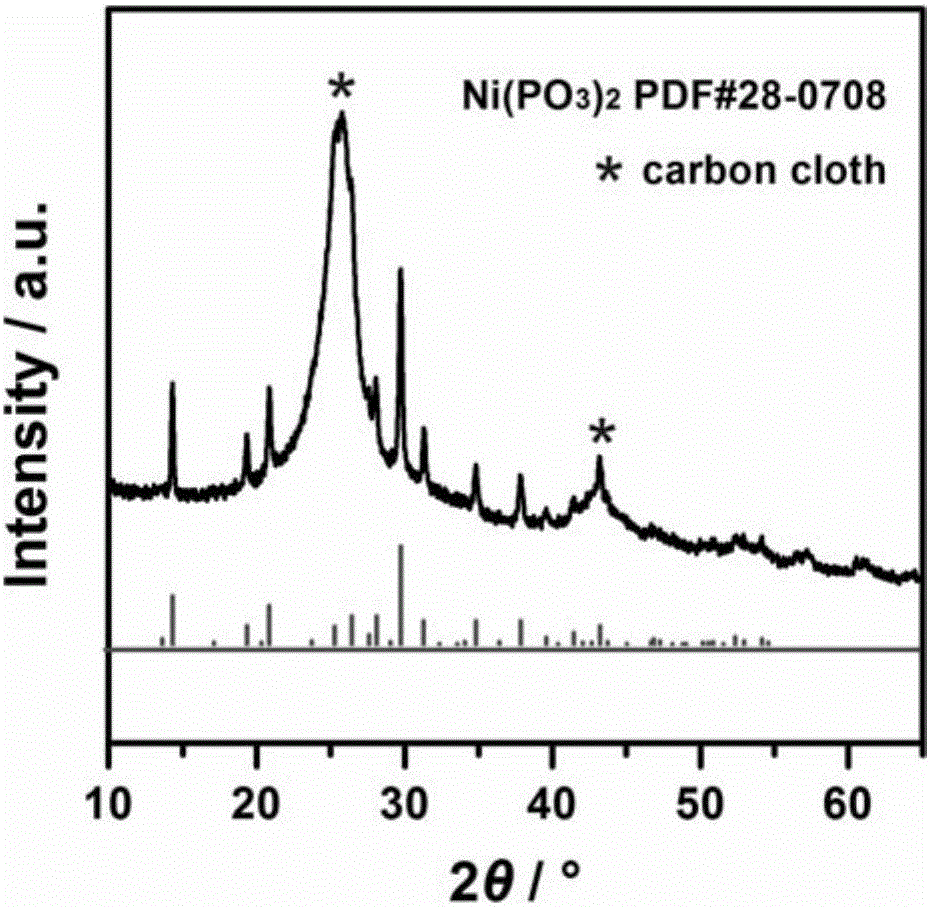

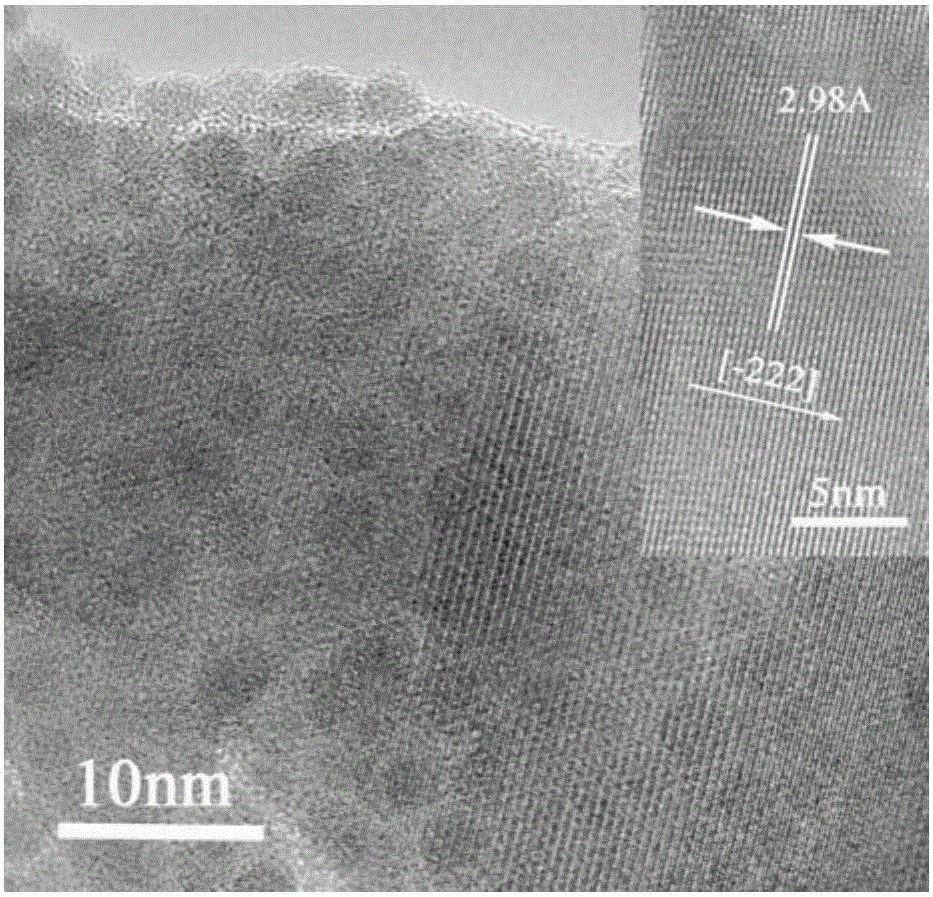

[0044] Put the nickel-containing precursor / carbon cloth composite prepared above into one side of an alumina crucible, and place 5 mmol of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com