Multifunctional additive for lubricating oil

A multifunctional, lubricating oil technology, applied in the field of lubricating oil, can solve the problem of single performance, achieve superior flame retardancy, and improve product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

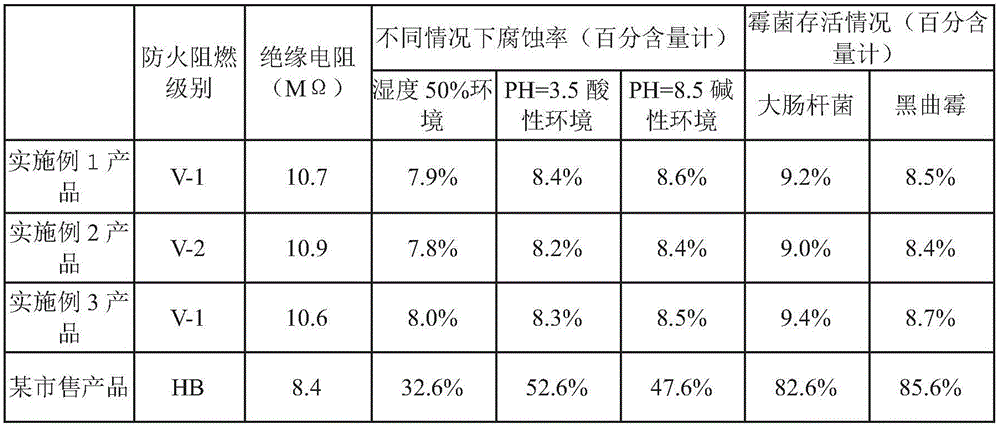

Examples

Embodiment 1

[0016] The lubricating oil multifunctional additive in the present embodiment is made up of the component of following mass fraction: polycarbonate 30 parts, bisphenol A polycarbonate 28 parts, terpene resin 28 parts, rosemary essential oil 26 parts, partial 28 parts of vinyl chloride, 28 parts of hydrogenated soybean oil, 26 parts of dimethyl carbonate, 28 parts of tung oil, 28 parts of hexadecyl bromide, 26 parts of sodium diacetate, 26 parts of ketoconazole, 26 parts of chitin, pine 28 parts of smoke ink, 26 parts of barium titanate powder, 24 parts of carbon powder, 28 parts of chromium carbide powder, 26 parts of silicon carbide powder, 24 parts of aluminum carbide powder, 26 parts of boron carbide powder, 24 parts of tungsten carbide powder, three Gan 24 parts of alcohol diisocaprylate, 26 parts of dibasic lead stearate, 26 parts of ammonium polyphosphate, 26 parts of ammonium dihydrogen phosphate, 26 parts of calcium dodecylbenzenesulfonate, 26 parts of sodium petroleum ...

Embodiment 2

[0022] The lubricating oil multifunctional additive in the present embodiment is made up of the following components in parts by mass: 32 parts of polycarbonates, 30 parts of bisphenol A polycarbonates, 30 parts of terpene resins, 28 parts of rosemary essential oils, partial 30 parts of vinyl chloride, 30 parts of hydrogenated soybean oil, 28 parts of dimethyl carbonate, 30 parts of tung oil, 30 parts of hexadecyl bromide, 28 parts of sodium diacetate, 28 parts of ketoconazole, 28 parts of chitin, pine 30 parts of smoke ink, 28 parts of barium titanate powder, 26 parts of carbon powder, 30 parts of chromium carbide powder, 28 parts of silicon carbide powder, 26 parts of aluminum carbide powder, 28 parts of boron carbide powder, 26 parts of tungsten carbide powder, three Gan 26 parts of alcohol diisocaprylate, 28 parts of dibasic lead stearate, 28 parts of ammonium polyphosphate, 28 parts of ammonium dihydrogen phosphate, 28 parts of calcium dodecylbenzenesulfonate, 28 parts of ...

Embodiment 3

[0028] The lubricating oil multifunctional additive in the present embodiment is made up of the following components in parts by mass: 34 parts of polycarbonates, 32 parts of bisphenol A polycarbonates, 32 parts of terpene resins, 30 parts of rosemary essential oils, 32 parts of vinyl chloride, 32 parts of hydrogenated soybean oil, 30 parts of dimethyl carbonate, 32 parts of tung oil, 32 parts of hexadecyl bromide, 30 parts of sodium diacetate, 30 parts of ketoconazole, 30 parts of chitin, pine 32 parts of smoke ink, 30 parts of barium titanate powder, 28 parts of carbon powder, 32 parts of chromium carbide powder, 30 parts of silicon carbide powder, 28 parts of aluminum carbide powder, 30 parts of boron carbide powder, 28 parts of tungsten carbide powder, triganium 28 parts of alcohol diisocaprylate, 30 parts of dibasic lead stearate, 30 parts of ammonium polyphosphate, 30 parts of ammonium dihydrogen phosphate, 30 parts of calcium dodecylbenzenesulfonate, 30 parts of sodium p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com