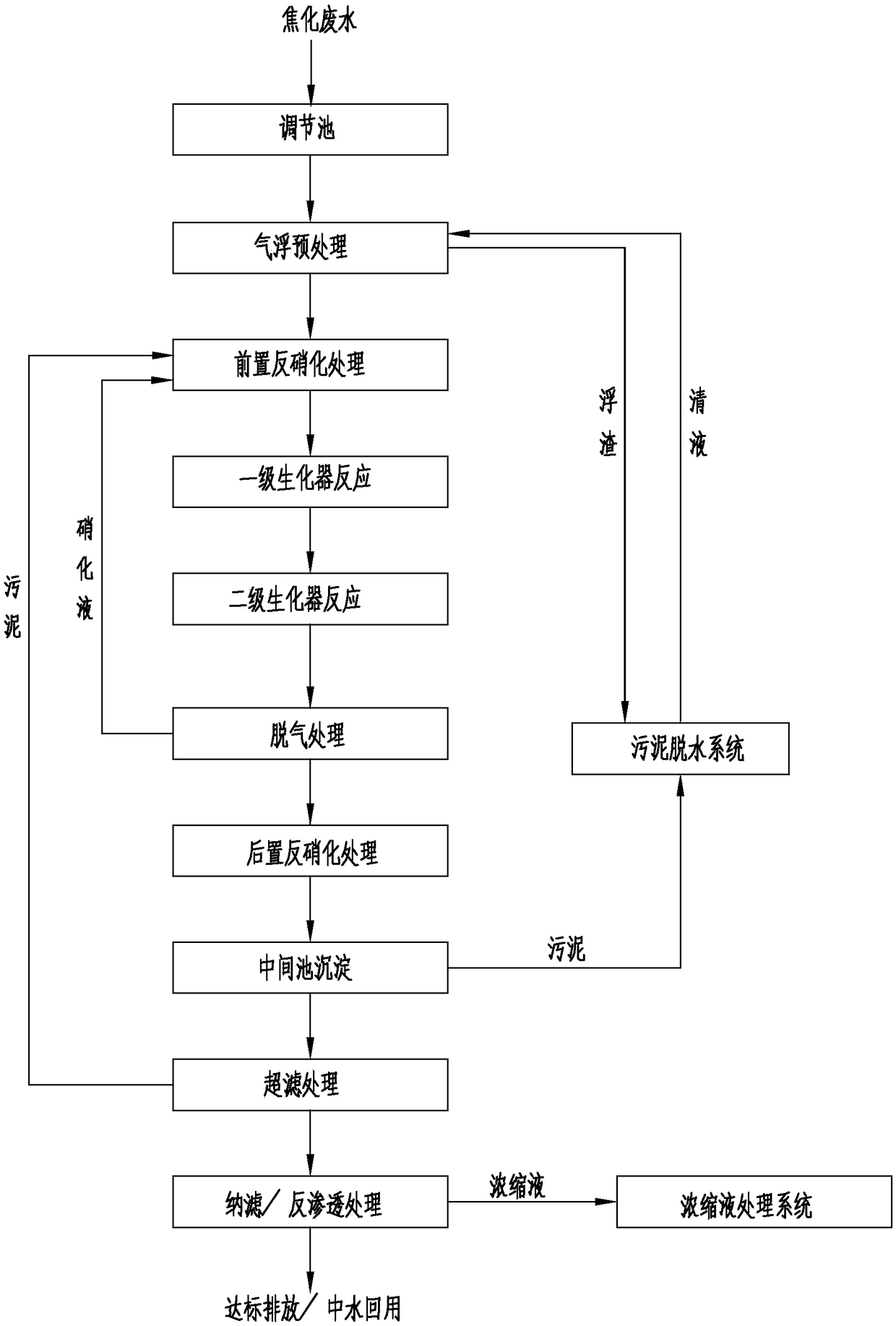

Treatment method of coking wastewater based on jet biochemical reactor

A biochemical reactor, coking wastewater technology, applied in chemical instruments and methods, biological water/sewage treatment, anaerobic digestion treatment, etc., can solve difficult to guarantee treatment effect, increase operating cost, low volume load and sludge load problems, to achieve the effect of improving efficiency and oxygen utilization, reducing treatment costs, and low sludge production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The coking wastewater is sent to the regulating tank for water quality and quantity adjustment. The water quality is 4500mg / L of COD, 800mg / L of BOD, 450mg / L of ammonia nitrogen, 700mg / L of volatile phenol, 30mg / L of cyanide, and the total Nitrogen concentration 500mg / L, SS concentration 50mg / L. Pass the coking wastewater in the regulating tank into the air flotation machine, the hydraulic retention time is 1h, the separated effluent is sent to the pre-denitrification tank, and the scum is sent to the sludge dewatering system, and it is tested according to the GB16171-2012 standard. The removal rate of oil and SS in coking wastewater is 90%, the removal rate of COD is 10%, the removal rate of BOD is 10%, the removal rate of ammonia nitrogen is 11%, the removal rate of total nitrogen is 10%, and the removal rate of volatile phenol is 14%. The removal rate of cyanide was 33%.

[0047] The pre-denitrification tank of the effluent after air flotation treatment is fully mix...

Embodiment 2

[0054] The coking wastewater is sent to the regulating tank for water quality and quantity adjustment. The water quality is 4500mg / L of COD, 800mg / L of BOD, 500mg / L of ammonia nitrogen, 700mg / L of volatile phenol, 30mg / L of cyanide, and the total Nitrogen concentration 500mg / L, SS concentration 50mg / L. The coking wastewater in the regulating tank is passed into the air flotation machine, the hydraulic retention time is 1.2h, the separated effluent is sent to the pre-denitrification tank, the scum is sent to the sludge dewatering system, and the mixing is added to the air flotation machine Coagulant and flocculant, according to mass percentage, the addition amount of coagulant is 0.005% of the total amount of coking wastewater, and the addition amount of flocculant is 0.01% of the total amount of coking wastewater. And tested according to the GB16171-2012 standard, the removal rate of oil and SS in coking wastewater after treatment is 92%, the removal rate of COD is 15%, the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com